Inner mixed and inner parallel hybrid lead-carbon battery and preparation method of negative electrode

A lead-carbon battery and hybrid technology, which can be used in the manufacture of lead-acid battery electrodes, hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., and can solve the problems of reducing the performance of the negative electrode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

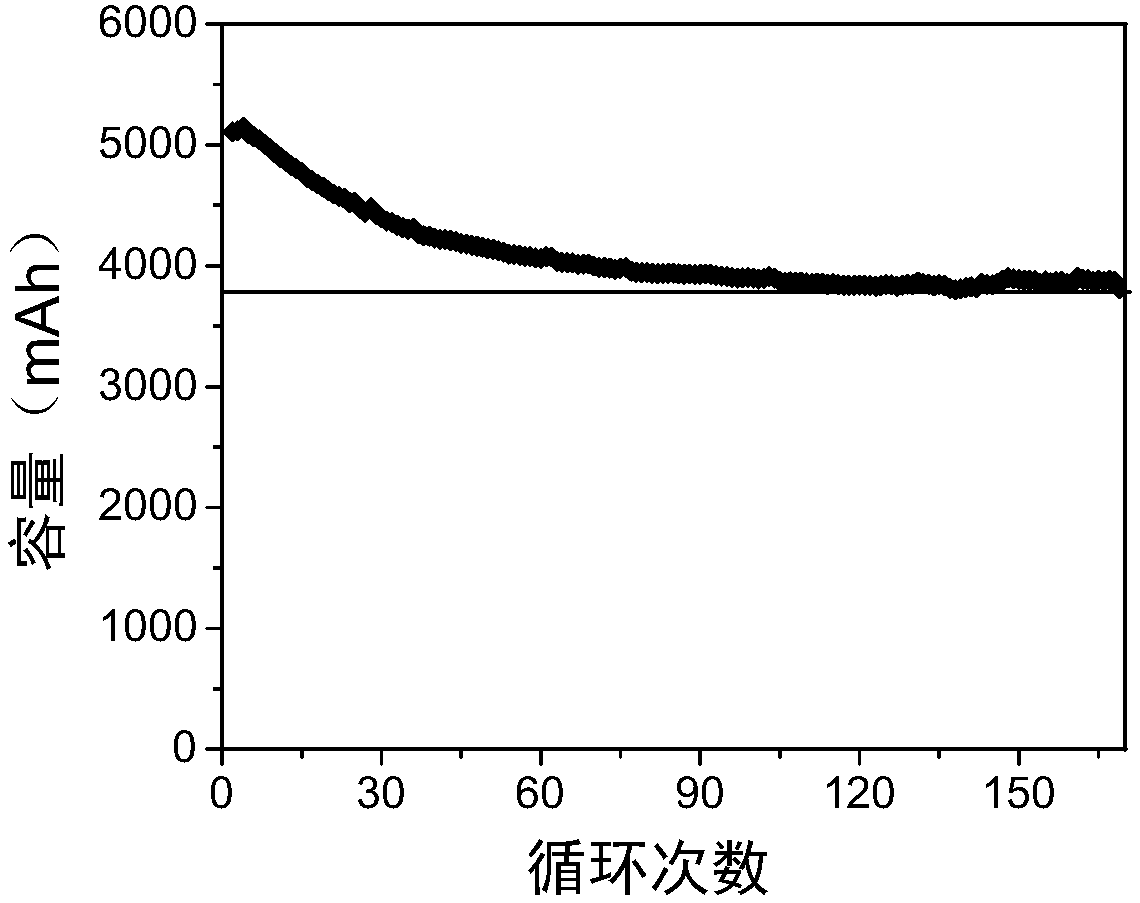

[0075] Take by weighing 2g of modified activated carbon-based composite additives, 0.5g of barium sulfate, 0.05g of short polypropylene fibers and 100g of lead powder with a length of 2mm, premix with a high-speed shear mixer, the rotating speed of the stirring paddle is 39000 rpm, and stir The time is 5 minutes. Add 10 g of water and a density of 1.25 g / cm to the resulting mixture 3 3g of sulfuric acid, fully stirred to obtain lead paste. Scrape-coat the lead paste on the grid, the thickness of the active material on the green electrode sheet is 1.5 mm, and cure and dry to obtain the lead-carbon battery composite negative electrode green electrode sheet. The curing temperature is 50°C, the relative humidity of the curing room is 90-100%, and the curing time is 24 hours; the drying temperature is 80°C, the relative humidity of the drying room is 2 . The prepared activated carbon negative plate was dried at 80 °C for 12 h. Then 2 pieces of negative plates of internal mixed l...

Embodiment 2

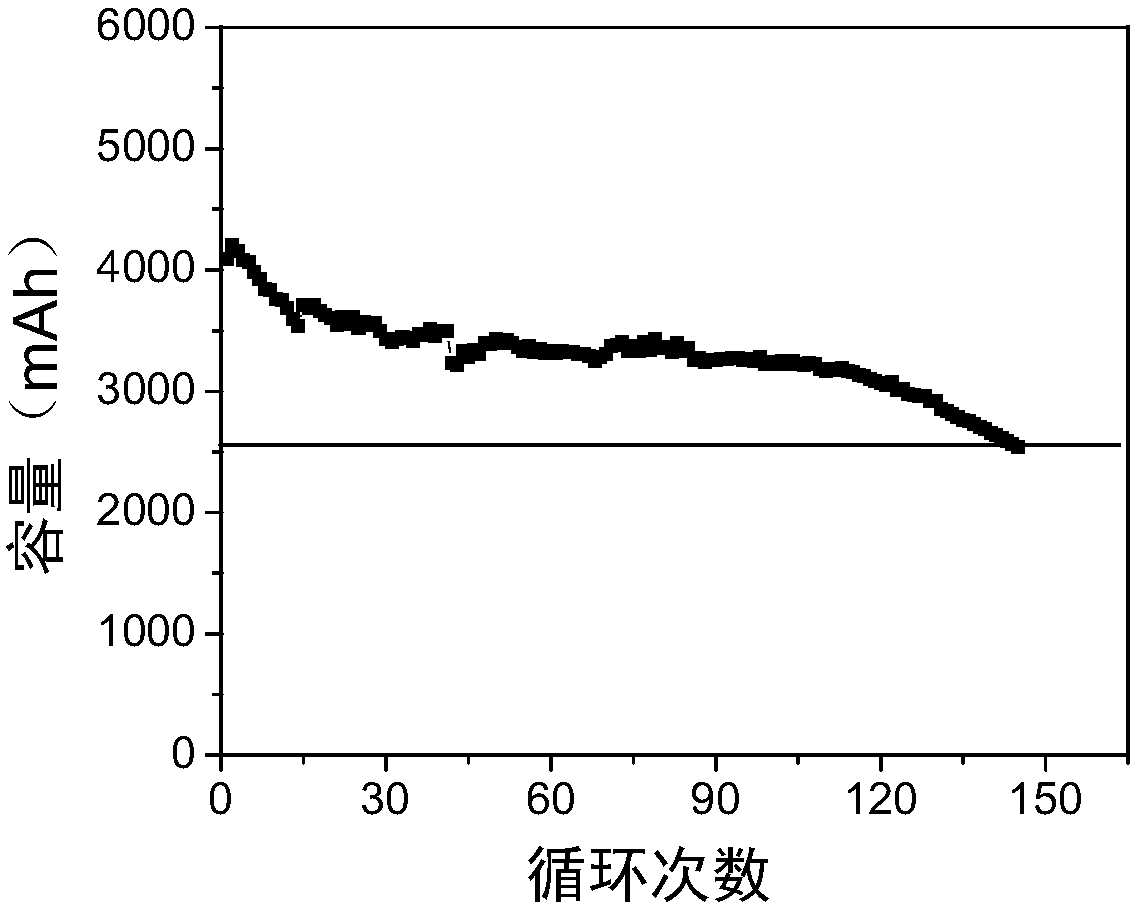

[0077] Take by weighing 2g of modified activated carbon-based composite additives, 0.5g of barium sulfate, 0.05g of short polypropylene fibers and 100g of lead powder with a length of 2mm, premix with a high-speed shear mixer, the rotating speed of the stirring paddle is 39000 rpm, and stir The time is 5 minutes. Add 10 g of water and a density of 1.25 g / cm to the resulting mixture 3 3g of sulfuric acid, fully stirred to obtain lead paste. Scrape the lead paste into 50% of the grid on the grid, and the thickness of the active material on the green electrode sheet is 1.5mm. Take by weighing activated carbon 85g, conductive agent 10g and binding agent 5g, mix uniformly to obtain charcoal paste; The charcoal paste obtained is coated on the negative electrode grid, and the coating amount of charcoal paste is 0.03g / cm 2 . After solidification and drying, the lead-carbon battery composite negative electrode green sheet is obtained. The curing temperature is 50°C, the relative hu...

Embodiment 3

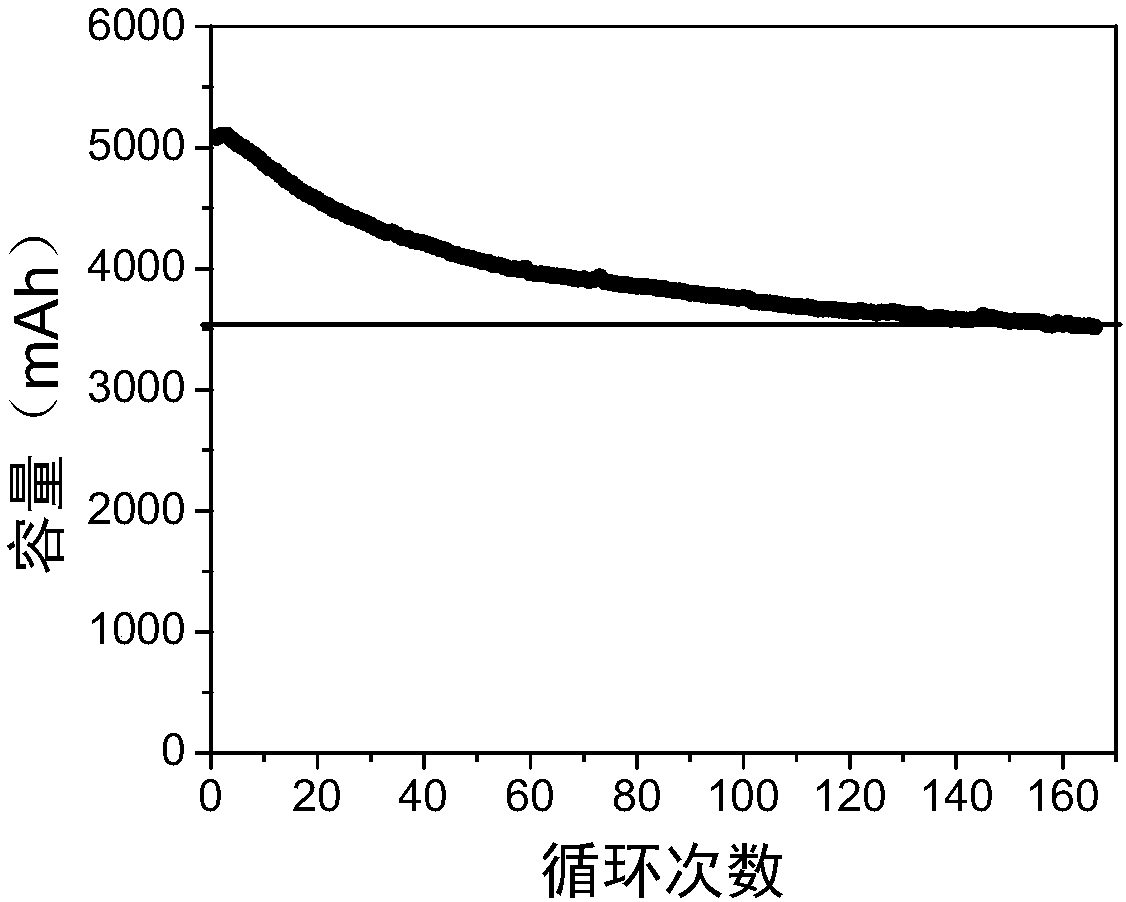

[0079] Take by weighing 2g of modified activated carbon-based composite additives, 0.5g of barium sulfate, 0.05g of short polypropylene fibers and 100g of lead powder with a length of 2mm, premix with a high-speed shear mixer, the rotating speed of the stirring paddle is 39000 rpm, and stir The time is 5 minutes. Add 10 g of water and a density of 1.25 g / cm to the resulting mixture 3 3g of sulfuric acid, fully stirred to obtain lead paste. Scrape-coat the lead paste on the grid, the thickness of the active material on the green electrode sheet is 1.5 mm, and cure and dry to obtain the lead-carbon battery composite negative electrode green electrode sheet. The curing temperature is 50°C, the relative humidity of the curing room is 90-100%, and the curing time is 24 hours; the drying temperature is 80°C, the relative humidity of the drying room is 2 . The prepared negative electrode plate coated with carbon paste was dried at 80° C. for 12 hours to obtain an internally mixed i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com