Nano activator of lead-acid storage battery and preparation method of nano activator

A lead-acid battery, activator technology, applied in lead-acid batteries, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problem of short service life of lead-acid batteries, incomplete repair function of repair fluid, The problems of long preparation period, etc., can inhibit the increase of particles, improve the electron transfer efficiency at the interface, and avoid the reaction between oxygen and negative spongy lead.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

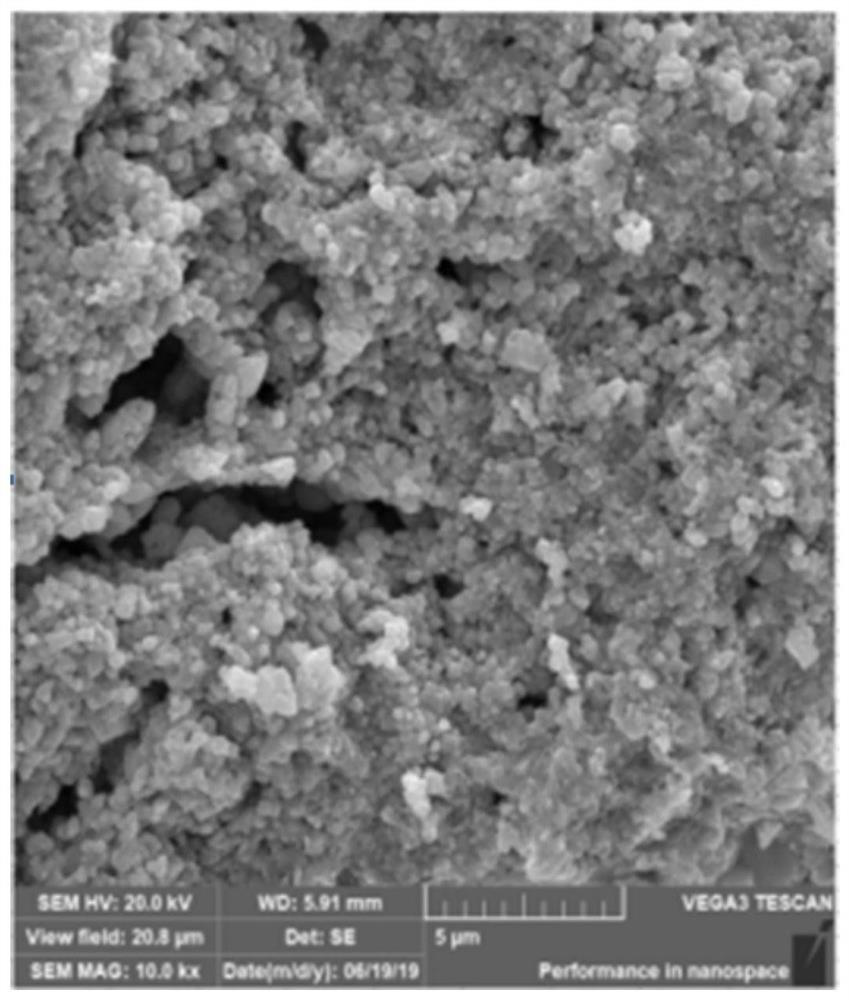

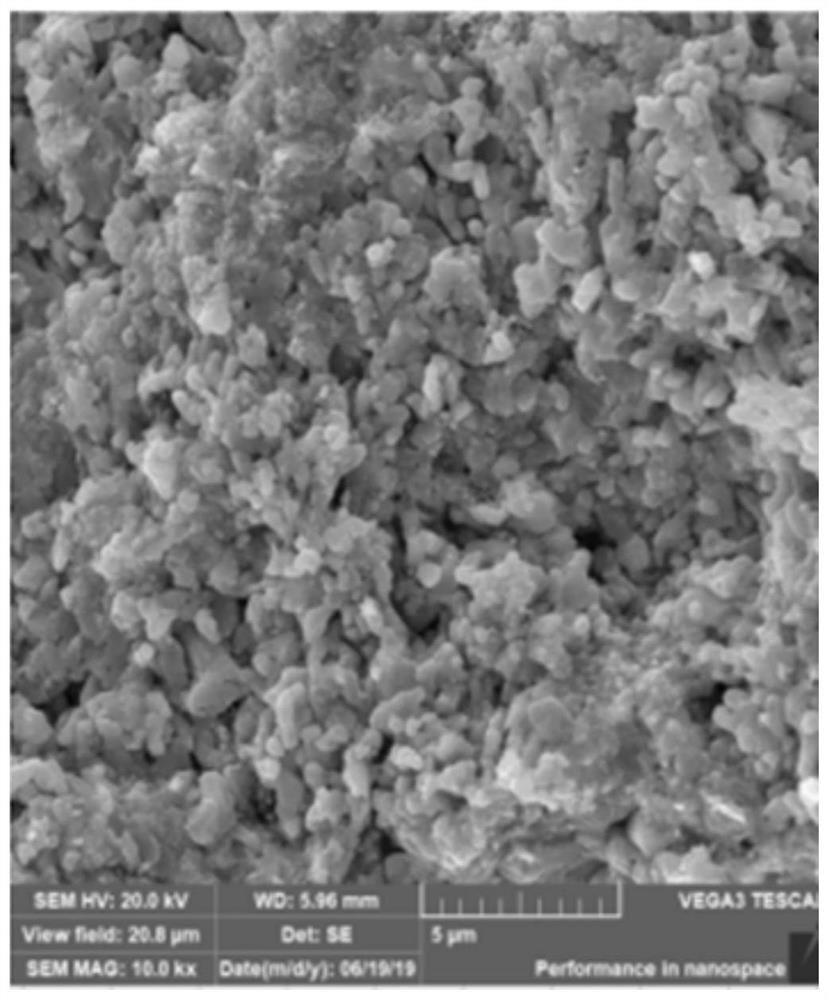

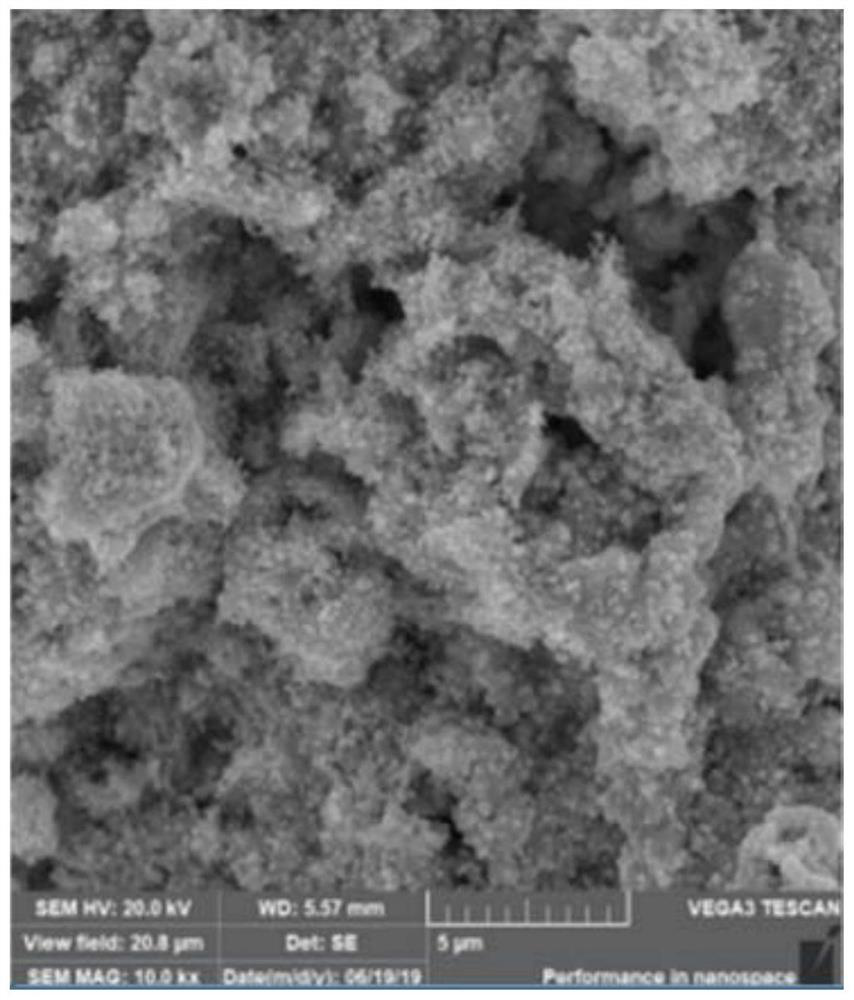

Image

Examples

Embodiment 1

[0031] A nanometer activator for a lead-acid battery, comprising the following raw materials by weight percentage: 6 parts of soluble metal salts, 0.5 parts of stannous sulfate, 3 parts of sodium polyvinyl sulfate, 5 parts of water-absorbing amine polymers, and 0.6 parts of polyvinylpyrrolidone parts, 0.3 parts of nano graphene oxide, 20 parts of sulfuric acid solution, 0.5 part of reducing agent, 4 parts of ammonium acetate, 45 parts of distilled water, wherein the soluble metal salt is the mixed salt of potassium sulfate, sodium sulfate, zinc sulfate, the potassium sulfate, sulfuric acid The mass ratio of sodium and zinc sulfate is 1.5:1:1.2; the water-absorbing amine polymers include polyacrylamide, polyacrylamide, and acrylic acid / acrylamide copolymer, which are copolymerized with polyacrylamide, polyacrylamide, and acrylic acid / acrylamide. The mass ratio of the materials is 1:1.2:1.0; the reducing agent is sodium p-hydroxybenzenesulfonate; the concentration of sodium polyv...

Embodiment 2

[0037]A nanometer activator for a lead-acid battery, comprising the following raw materials in percentage by weight: 8 parts of soluble metal salts, 0.8 parts of stannous sulfate, 6 parts of sodium polyvinyl sulfate, 7 parts of water-absorbing amine polymers, and 0.9 parts of polyvinylpyrrolidone parts, 0.55 parts of nano graphene oxide, 33 parts of sulfuric acid solution, 0.75 parts of reducing agent, 7 parts of ammonium acetate, 60 parts of distilled water, wherein the soluble metal salt is the mixed salt of potassium sulfate, sodium sulfate, copper sulfate, calcium chloride, the The mass ratio of potassium sulfate, sodium sulfate, copper sulfate, and calcium chloride is 1.5:1:1.2:1.3; the water-absorbing amine polymers include polyacrylamide, polyacrylamide, and acrylic acid / acrylamide copolymer. , polyacrylamide, acrylic acid / acrylamide copolymer mass ratio of 1:1.5:1.2; the reducing agent is sodium p-hydroxybenzenesulfonate and sodium hydroxymethanesulfonate; the concentra...

Embodiment 3

[0043] A nanometer activator for a lead-acid battery, comprising the following raw materials by weight percentage: 12 parts of soluble metal salts, 1 part of stannous sulfate, 8 parts of sodium polyvinyl sulfate, 9 parts of water-absorbing amine polymers, and 1.2 parts of polyvinylpyrrolidone parts, 0.8 parts of nano graphene oxide, 40 parts of sulfuric acid solution, 1 part of reducing agent, 10 parts of ammonium acetate, 75 parts of distilled water, wherein the soluble metal salts are potassium sulfate, sodium sulfate, zinc sulfate, copper sulfate, calcium chloride, chlorine The mixed salt of barium chloride, the mass ratio of the potassium sulfate, sodium sulfate, zinc sulfate, copper sulfate, calcium chloride, barium chloride is 1.5:1:1.2:1:1.2:1; Acrylic amine, polyacrylamide, acrylic acid / acrylamide copolymer, the mass ratio of the polyacrylamide, polyacrylamide, acrylic acid / acrylamide copolymer is 1:1.8:1.5; the reducing agent is sodium methylolsulfonate; The concentra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com