Super-junction device

A super-junction device and device technology, applied in the field of semiconductor integrated circuits, can solve the problems of increasing device cost, increasing device specific on-resistance, and high cost, and achieve the effects of reducing epitaxial cost, increasing breakdown voltage, and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

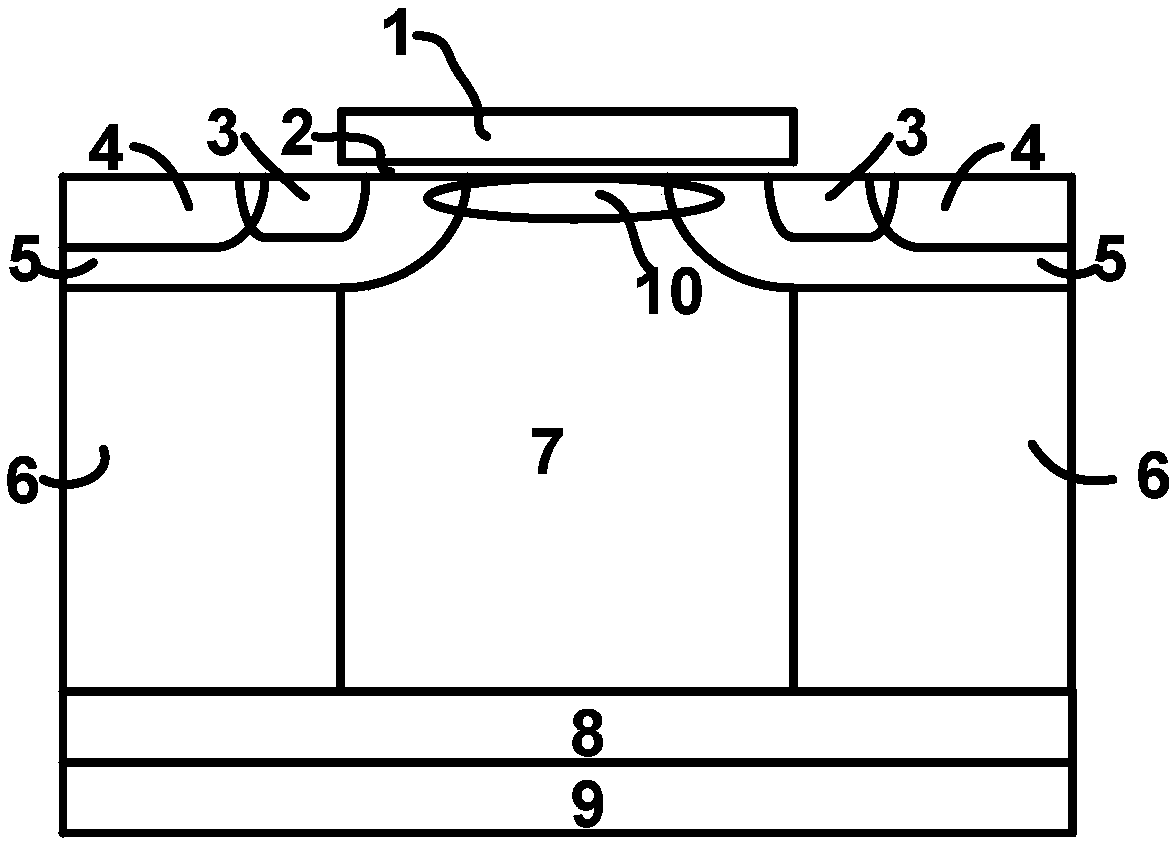

[0074] The three structures are compared below, and the thickness of the drift region of the three structures, that is, the N-type column 7 plus the buffer layer, is 60 μm. The depth of the groove, that is, the P-type pillar 6 is 40 μm. The width of the opening at the top of the trench and the distance between the trenches are the same, and the angle of trench etching and the doping dose of the filled P-type columns are the same.

[0075] The first structure: the width of the drift region, that is, the longitudinal thickness is 40 μm, the width of the buffer layer, that is, the longitudinal thickness is 20 μm, and the doping concentration of the drift region and the buffer layer are the same, that is, 2.93e15 / cm 3 .

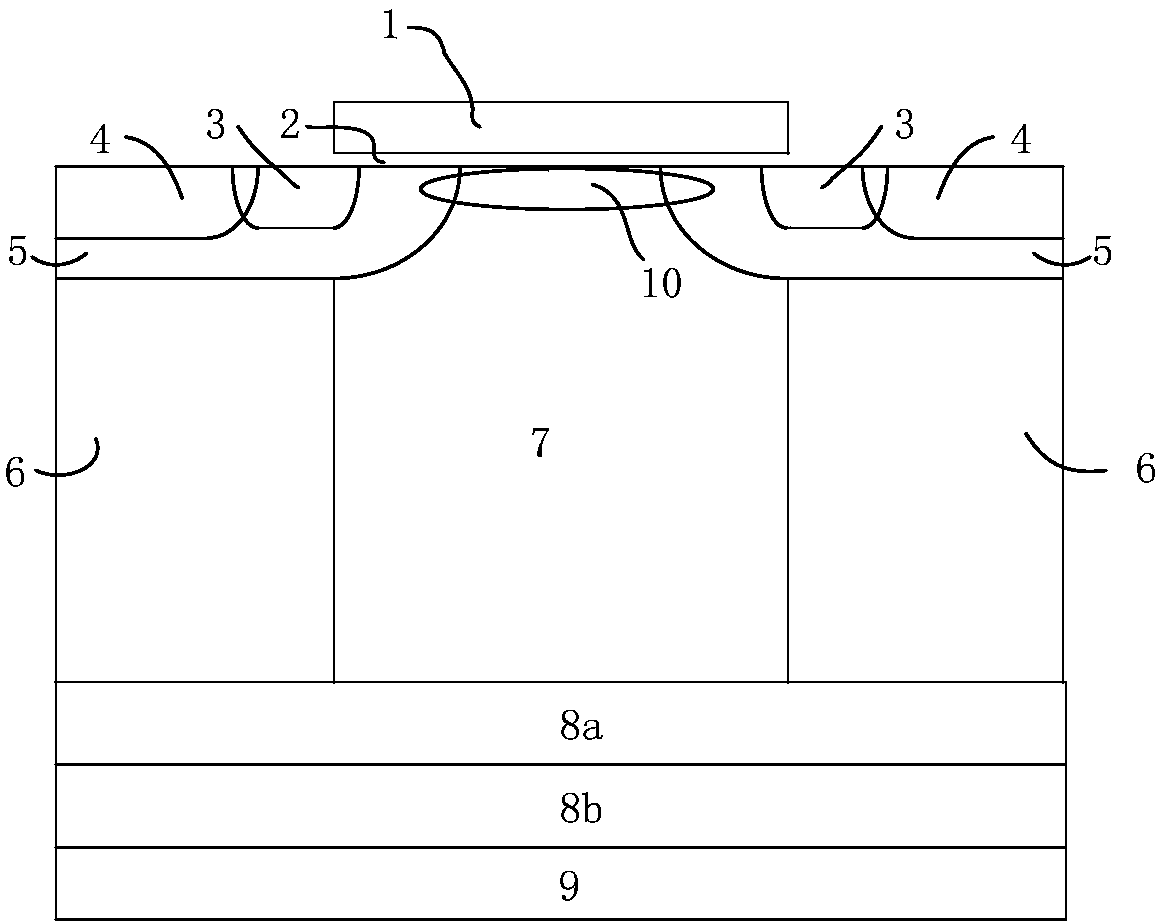

[0076] The second structure: the width of the drift region is 40μm, the buffer layer is divided into two layers, the first layer is image 3 The width of the second buffer sublayer 8a shown is 10 μm, and the corresponding doping concentration is 1.0e15 / cm 3 , th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com