Five-phase inverter and double three-phase motor system driving circuit and direct torque control method

A five-phase inverter and drive circuit technology, which is applied in motor generator control, AC motor control, electronic commutation motor control, etc., can solve the problems of complex calculation process and difficulty in quick response, and achieve strong robustness, Simple structure and improved control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

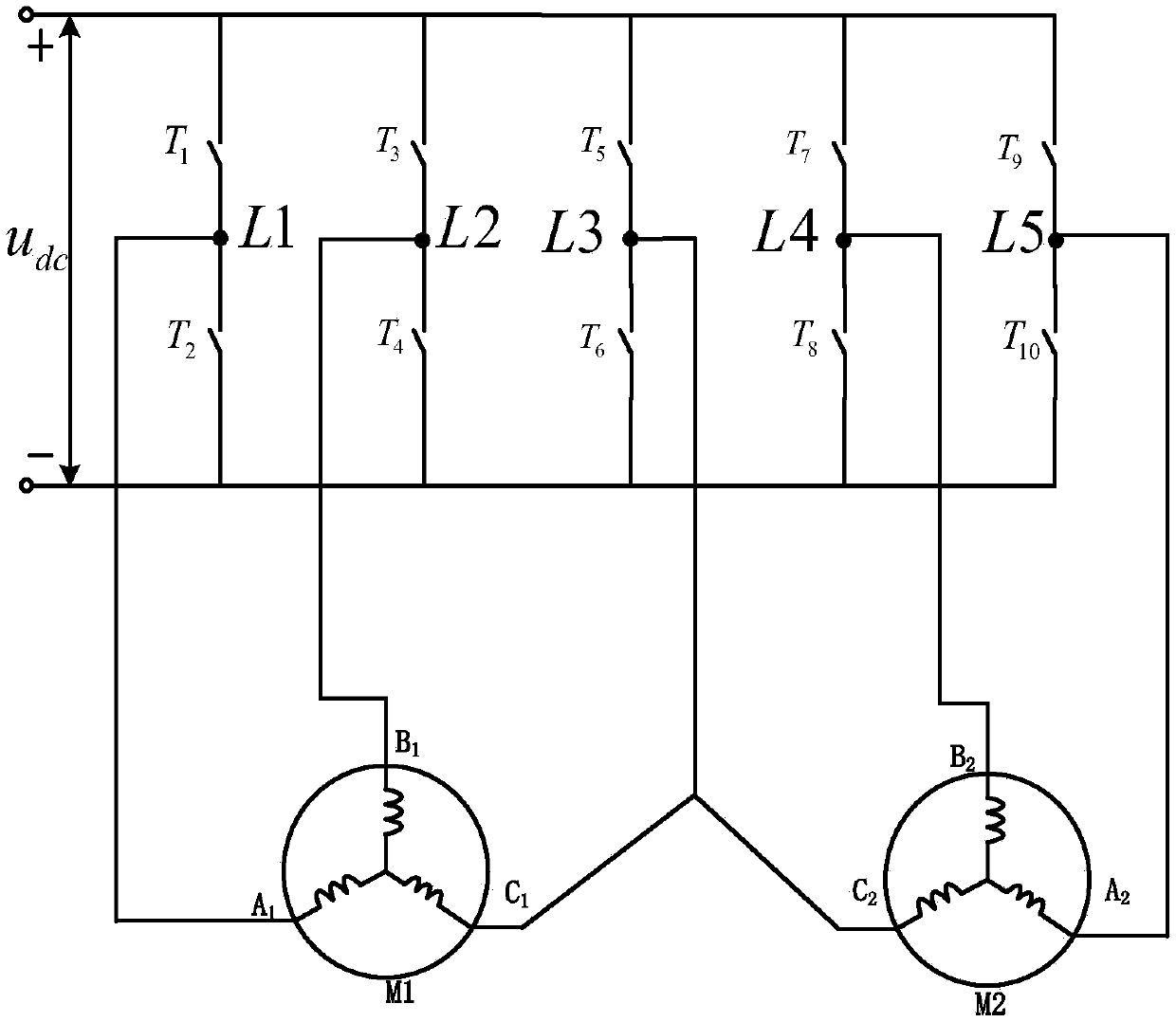

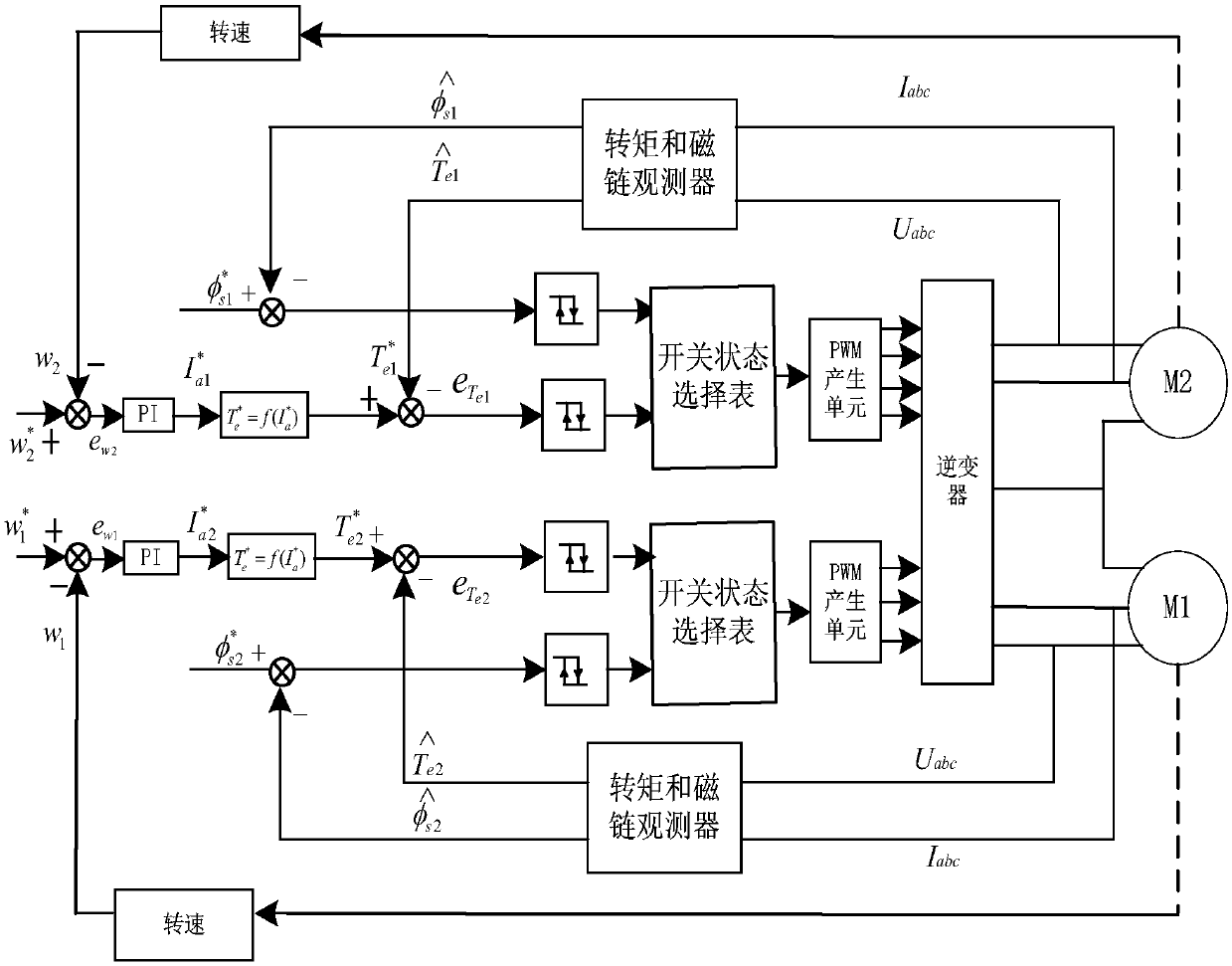

[0029] see figure 1 , the five-phase inverter dual three-phase motor system of the present invention includes the first, second, third, fourth, and fifth inverter bridge arms L1, L2, L3, L4, L5 and the first star-shaped winding three-phase motor M1, The second star-shaped winding three-phase motor M2; the first, second, third, fourth, and fifth inverter bridge arms L1, L2, L3, L4, and L5 are connected in parallel and connected to the public DC power supply; wherein, the first inverter The bridge arm L1, the second inverter bridge arm L2, the fourth inverter bridge arm L4 and the fifth inverter bridge arm L5 are independent bridge arms, and the centers of the bridge arms are respectively connected to the first star winding three-phase motor M1 The two-phase winding A1, B1 of the two-phase winding A2, B2 of the three-phase motor M2 of the second star winding; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com