A waste gas purification system

A technology of exhaust gas purification system and purification device, which is applied in the direction of chemical instruments and methods, separation methods, and separation of dispersed particles, can solve the problems of unreasonable purification structure, poor purification effect, and large volume, so as to ensure miscible speed, Improve miscibility efficiency and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

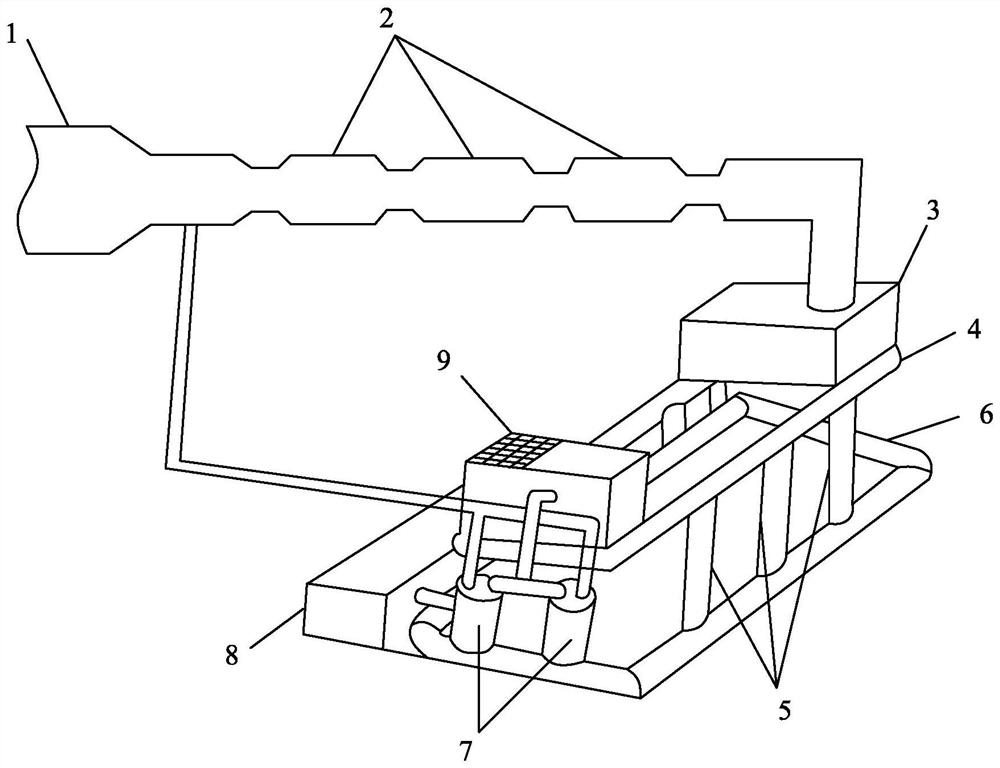

[0031] Such as figure 1 The waste gas purification system includes: diameter reducing device 1, high-speed miscibility device 2, volume fan 3, fluid distribution device 4, aeration purification device 5, flow gathering device 6, solid-liquid separator 7, functional cycle Device 8 and ultimate purification device 9;

[0032] One end of the reducing device 1 is connected to the exhaust gas output pipeline, and the other end is connected to the high-speed mixing device 2;

[0033] The high-speed miscibility device 2 includes: a plurality of special-shaped liquid injection heads are arranged in the device body, and a Venturi tube for realizing the Venturi effect and an ozone generator for generating ozone are designed;

[0034] The liquid supply pipeline of the special-shaped liquid injection head is connected with the output pipeline of the liquid supply pump of the purification liquid;

[0035] The output port of the ozone generator is set at the inlet position of the high-spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com