Color-plating and laser-etching glass-imitating and ceramic treatment method of mobile phone shell and mobile phone shell exterior part

A treatment method, laser engraving technology, applied in the direction of pretreatment surface, sputtering coating, vacuum evaporation coating, etc., can solve the problems of easy broken glass, poor metal signal, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

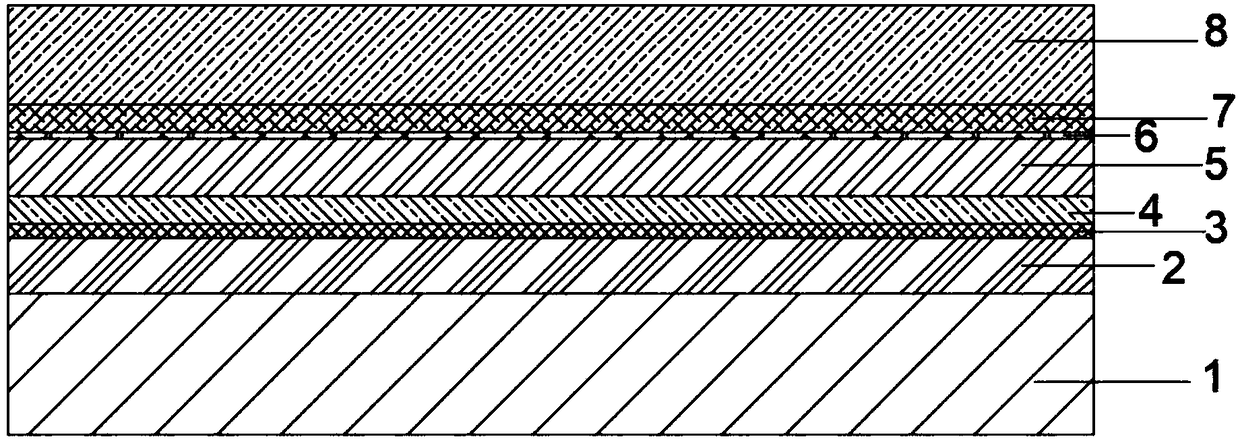

[0031] In order to further understand the characteristics, technical means and the specific purpose and function of the present invention, please refer to figure 1 , a mobile phone plastic appearance part is shown in the figure, comprising a plastic base material, characterized in that, the surface of the plastic base material 1 is sequentially formed with a UV paint layer 2, a first vacuum coating layer 3, a transparent protective Layer 4, UV transparent electroplating bottom layer 5, second vacuum coating layer 6, middle paint layer 7, top paint layer 8.

[0032] Among them, the UV color paint layer 2 has the effect of covering the defects of the plastic substrate 1 and enhancing the adhesion, has rich colors and texture effects, and acts as the carrier of the first vacuum coating layer 3 at the same time; the first vacuum coating layer 3 has a metallic texture and can It has the effect of high bright edge; the transparent protective layer 4 has the function of protecting th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com