Ammonium bicarbonate recrystallization production method

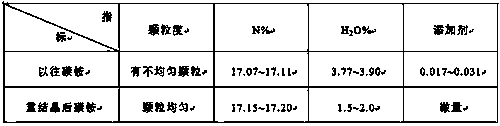

An ammonium bicarbonate, production method technology, applied in solution crystallization, general layout of crystallization device, ammonium carbonate/acid carbonate, etc., can solve the problem of high product quality requirements, affecting product quality, additive impurities and other problems to achieve the effect of increasing ammonium bicarbonate production, low moisture content and good particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

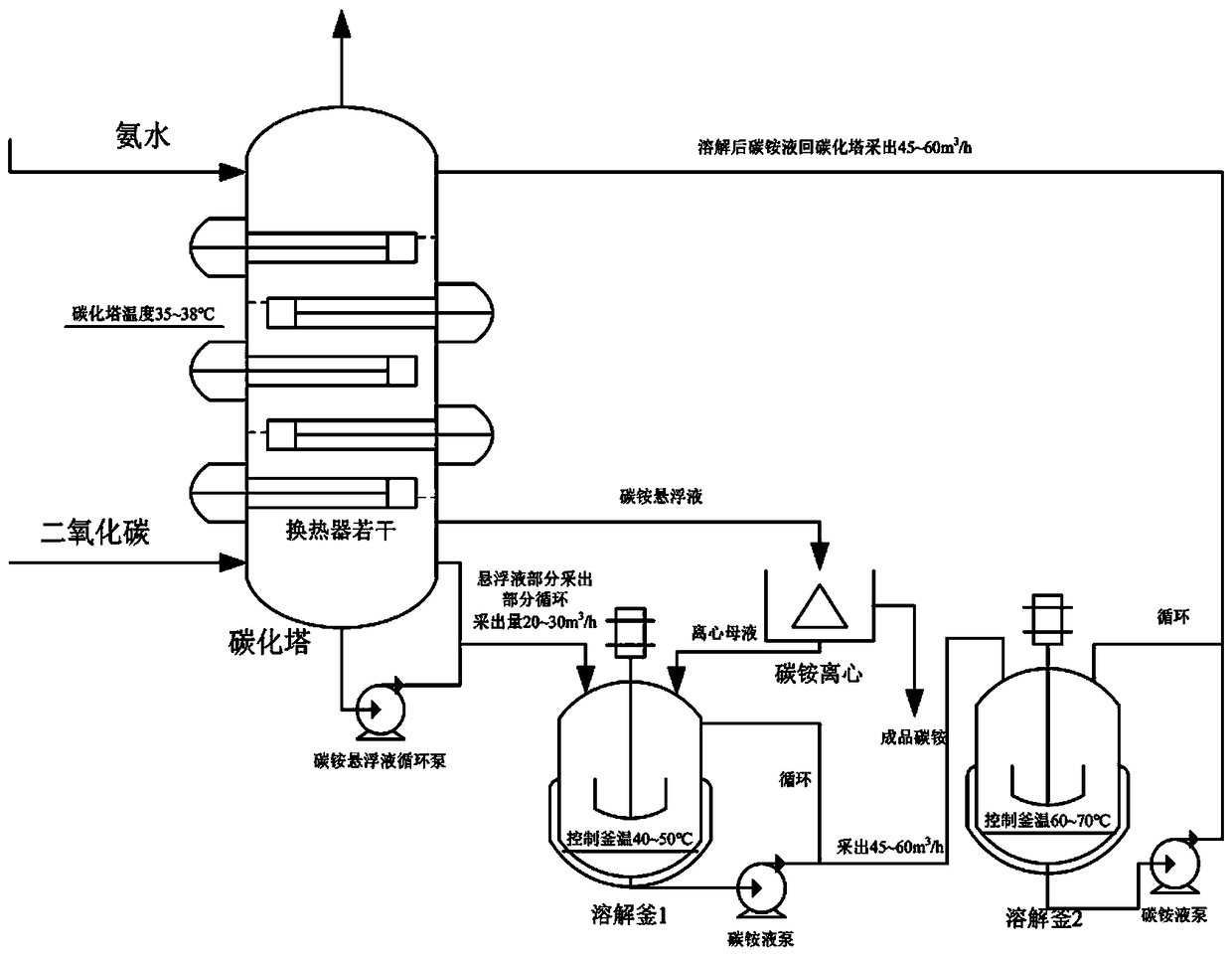

[0019] like figure 1 As shown, ammonia water from melamine and CO 2 The gas enters the carbonization tower, and the temperature of the carbonization tower is controlled at 35~38°C, and the reaction generates ammonium bicarbonate suspension, and the circulation pump of the carbonization tower is turned on, and the circulation flow rate is controlled to be 100~130m 3 / h, control output 20~25m 3 / h to the dissolution kettle 1.

[0020] Pour part of the ammonium bicarbonate suspension in the carbonization tower into the centrifuge for centrifugation to produce finished ammonium bicarbonate. Ammonium bicarbonate centrifugal mother liquor according to 25 ~ 30m 3 / h is pumped into the dissolving kettle 1 to mix with the previously mined ammonium bicarbonate suspension, and the circulation volume of the dissolving kettle 1 is 90~120m 3 / h, the temperature is controlled at 40~50℃, and the output is 45~55m 3 / h to the dissolution kettle 2, the circulation volume of the dissolution ...

Embodiment 2

[0024] like figure 1 As shown, ammonia water from melamine and CO 2 The gas enters the carbonization tower, and the temperature of the carbonization tower is controlled at 35~38°C, and the reaction generates ammonium bicarbonate suspension, and the circulation pump of the carbonization tower is turned on, and the circulation flow rate is controlled to be 100~130m 3 / h, control output 25~30m 3 / h to the dissolution kettle 1, and evenly mixed with the centrifuged mother liquor of ammonium bicarbonate, and the mother liquor was 3 / h pumped into the dissolution kettle 1, the circulation volume of the dissolution kettle 1 is 90~120m 3 / h, the temperature is controlled at 40~50℃, and the output is 50~60m 3 / h to the dissolution kettle 2, the circulation volume of the dissolution kettle 2 is 90~120m 3 / h, the temperature is controlled at 60~70℃, and the output is 50~60m 3 / h to the carbonization tower, thus forming a cycle, continuous production of ammonium bicarbonate, the outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com