Preparation method of ternary positive electrode material precursor

A technology of cathode materials and precursors, which is applied in the field of preparation of ternary cathode material precursors, can solve the problems of wide particle size distribution of ternary cathode material precursors, and achieve uniform size, improved performance, and good circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

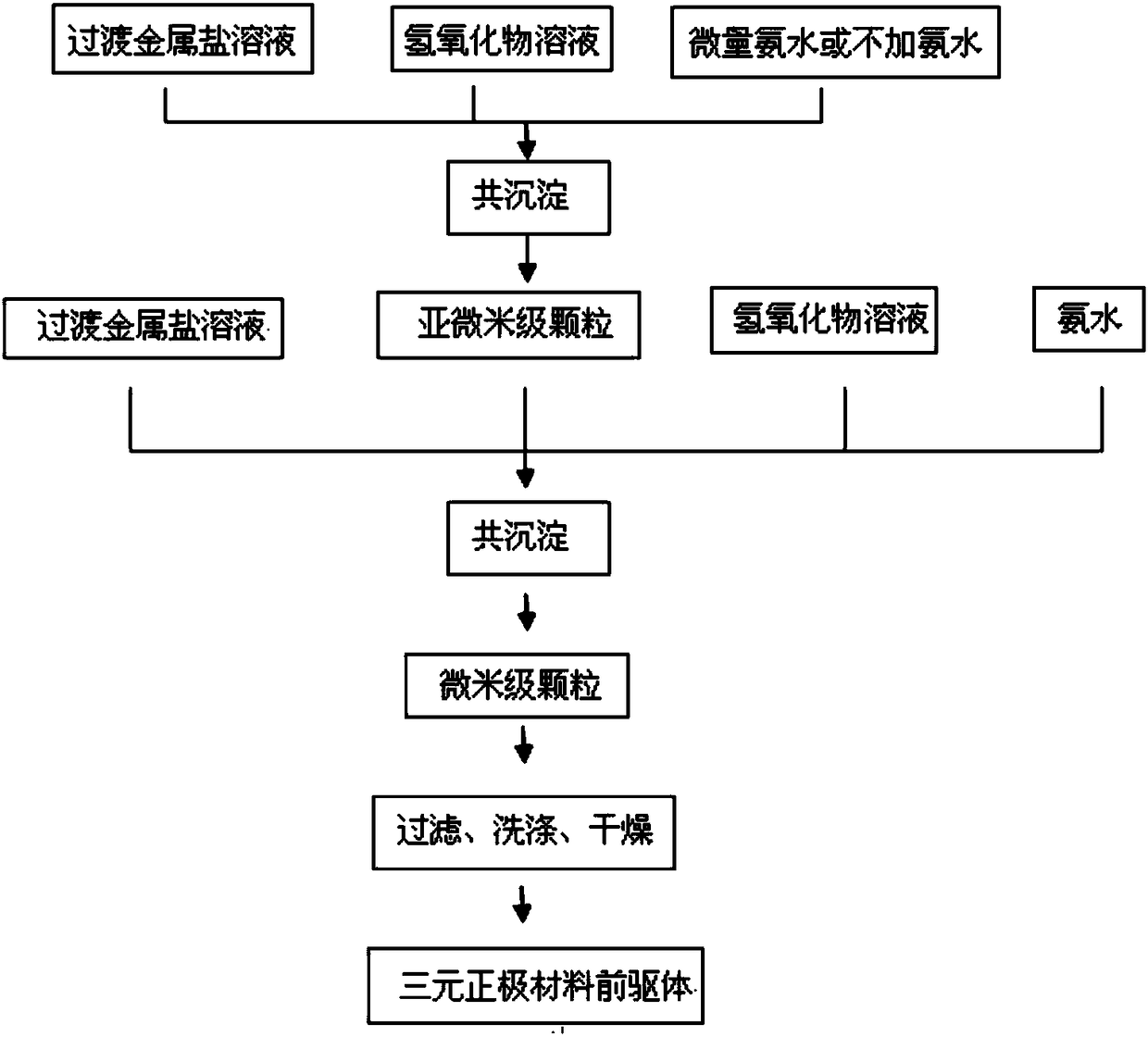

Method used

Image

Examples

Embodiment 1

[0026] 1. Preparation of submicron particles: 2.0mol / L MSO 4 (M=Ni, Co, Mn, where the molar ratio of Ni:Co:Mn is 0.8:0.1:0.1) solution and 5.0mol / L NaOH solution were added dropwise to the reaction vessel at a rate of 1ml / min, and at the same time, Nitrogen, under the conditions of pH 11.0 and temperature 55°C, carry out co-precipitation reaction for 1 hour to obtain a mixed solution containing submicron particles;

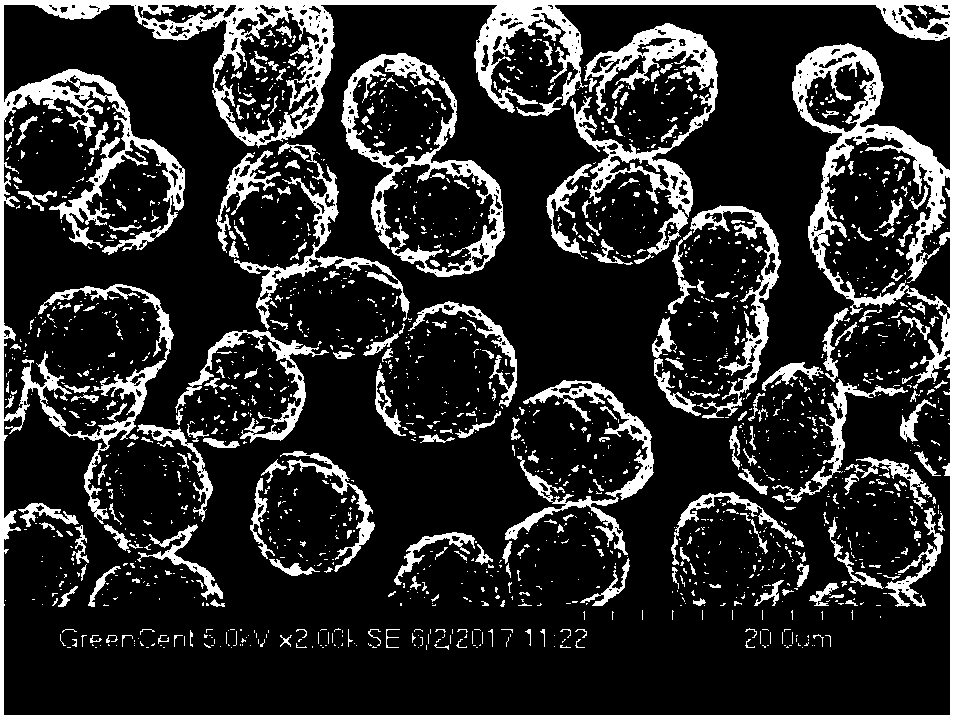

[0027] 2. Preparation of the precursor of the ternary cathode material: add ammonia water to the mixed solution prepared in step (1) to obtain a reaction solution, and control the concentration of ammonia water in the reaction solution to 0.3mol / L, and continue to add 2.0mol / L of MSO 4 (M=Ni, Co, Mn, where Ni: Co: Mn molar ratio is 0.8: 0.1: 0.1) solution and 5.0mol / L NaOH solution, continue to feed nitrogen, at pH 11.0, temperature 50 ℃ Co-precipitation reaction was carried out under the conditions for 25h. After the reaction was completed, Ni was obtained by f...

Embodiment 2

[0030] 1. Preparation of submicron particles: 2.5mol / L MCl 2 (M=Ni, Co, Mn, where Ni:Co:Mn molar ratio is 0.7:0.1:0.2) solution and 2.0mol / L KOH solution were added dropwise to the reaction vessel at a rate of 2ml / min, and ammonia water was added at the same time , and control the concentration of ammonia water in the solution to be 0.02mol / L, pass nitrogen gas, and carry out co-precipitation reaction for 1 hour under the conditions of pH value of 12.0 and temperature of 25°C to obtain a mixed solution containing submicron particles;

[0031] 2. Preparation of the precursor of the ternary positive electrode material: add ammonia water to the mixed solution prepared in step (1) to obtain a reaction solution, and control the concentration of ammonia water in the reaction solution to 0.1mol / L, and continue to add 2.0mol / L MCl 2 (M=Ni, Co, Mn, where the molar ratio of Ni: Co: Mn is 0.7: 0.1: 0.2) solution and 2.0mol / L KOH solution, continue to feed nitrogen, at pH value 8.0, temp...

Embodiment 3

[0034] 1. Preparation of submicron particles: 1.5mol / L of M(NO 3 ) 2 (M=Ni, Co, Mn, wherein the molar ratio of Ni: Co: Mn is 0.6: 0.2: 0.2) solution and 8.0mol / L KOH solution were added dropwise to the reaction vessel at a rate of 0.5.ml / min, and passed into Nitrogen, under the conditions of pH value 8.0 and temperature 45°C, the co-precipitation reaction was carried out for 3 hours to obtain a mixed solution containing submicron particles;

[0035] 2. Preparation of the precursor of the ternary cathode material: add ammonia water to the mixed solution prepared in step (1) to obtain a reaction solution, and control the concentration of ammonia water in the reaction solution to 0.2mol / L, and continue to add 1.5mol / L of M(NO 3 ) 2 (M=Ni, Co, Mn, where Ni: Co: Mn molar ratio is 0.6: 0.2: 0.2) solution and 8.0mol / L KOH solution, continue to feed nitrogen, at pH 12.0, temperature 80 ℃ Co-precipitation reaction was carried out under the conditions for 15h. After the reaction was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com