Folding-resistant and high-transparency mirror surface polyurethane resin, and preparation method and application thereof

A polyurethane resin, translucent technology, applied in the field of polyurethane resin, can solve the problems of poor folding resistance, poor folding resistance, easy migration, etc., and achieve excellent abnormal low temperature folding resistance, good surface smoothness, adhesive film The effect of high light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The polyester diol used in this embodiment is polyadipate glutarate 1,4-butylene glycol ester diol (A) and polyadipate 1,4-butylene glycol ester diol (B) , the mol ratio of adipic acid and glutaric acid in (first) is 3:7, and number average molecular weight is 2000; The number average molecular weight of (second) is 2000; Wherein (first): (second)=3:1 (weight Compare);

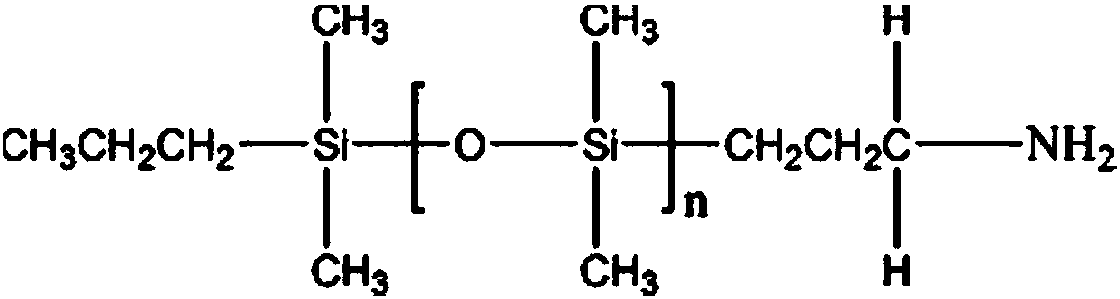

[0060] The single-end amino silicone oil used in this example has a molecular weight of 800.

[0061] Sample B1 is prepared in this embodiment, wherein the raw materials and weight of sample B1 are as follows:

[0062] raw material name

weight / g)

percentage(%)

Antioxidant BHT

1.00

0.02%

441

11%

Polyester diol (B)

147

3.7%

1,4-Butanediol

142.5

3.6%

4,4'-Diphenylmethane diisocyanate

469.3

11.7%

2400

59.9%

400

10%

Single-ended amino silicone oil...

Embodiment 2

[0070] The polyester diol used in this embodiment is polyadipate glutarate 1,4-butylene glycol ester diol (A) and polyadipate 1,4-butylene glycol ester diol (B) , the mol ratio of adipic acid and glutaric acid in (first) is 1:1, and number average molecular weight is 3500; The number average molecular weight of (second) is 2000; Wherein (first): (second)=3:2 (weight Compare);

[0071] The single-end amino silicone oil used in this example has a molecular weight of 1000.

[0072] Sample B2 is prepared in this embodiment, wherein the raw materials and weight of sample B2 are as follows:

[0073] raw material name

weight / g)

percentage(%)

Antioxidant BHT

1.00

0.02%

338.4

8.4%

Polyester diol (B)

225.6

5.6%

1,4-Butanediol

154

3.8%

4,4'-Diphenylmethane diisocyanate

484.2

12.1%

2400

59.9%

400

10%

Single-ended amino silicone...

Embodiment 3

[0081] The polyester diol used in this embodiment is polyadipate glutarate 1,4-butylene glycol ester diol (A) and polyadipate 1,4-butylene glycol ester diol (B) , the mol ratio of adipic acid and glutaric acid in (A) is 7:3, and the number average molecular weight is 1000; The number average molecular weight of (B) is 2000; Wherein (A): (B)=1:1 (weight Compare);

[0082] The single-end amino silicone oil used in this example has a molecular weight of 1000.

[0083] Sample B3 is prepared in the present embodiment, wherein the raw materials and weight of sample B3 are as follows:

[0084]

[0085]

[0086] The preparation steps of sample B3 are as follows:

[0087] 1), antioxidant BHT, polyester diol (A), polyester diol (B), 1,4-butanediol, dimethylformamide (55% of the total weight) are mixed at 60°C Uniform;

[0088] 2), then add 4,4'-diphenylmethane diisocyanate (95% of the total weight), heat up to 80°C, and keep warm for 4 hours;

[0089] 3), add the 4,4'-dipheny...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com