Fast detection method of large substrate of liquid-crystal display screen

A liquid crystal display and detection method technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as unclear problem and cause, low assembly cost, low investment cost, economic loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] This embodiment provides a rapid detection method for a large substrate of a liquid crystal display, including:

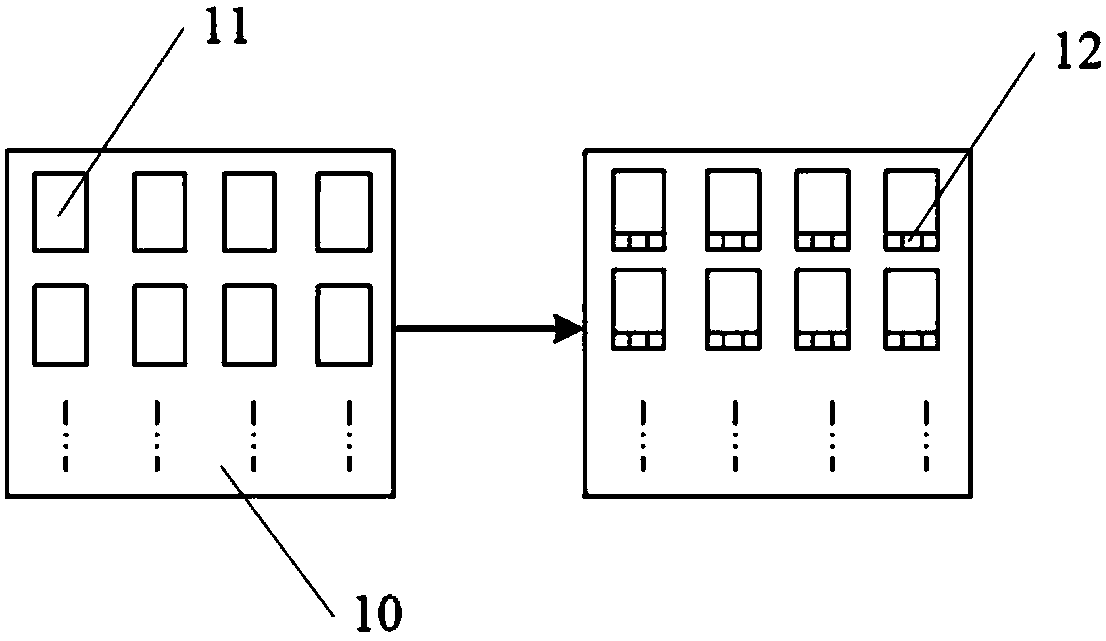

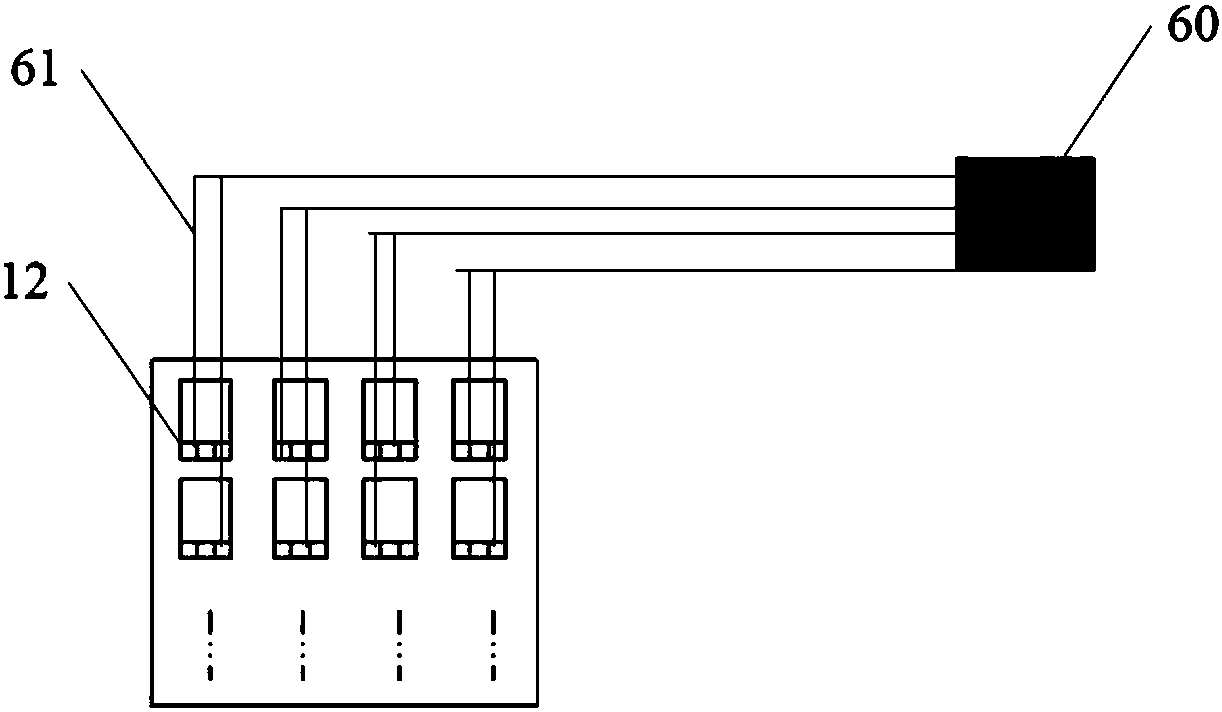

[0025] like figure 1 As shown, the large display substrate 10 of Cell into a box is cut at the IC control position 12, and the electrical measurement IC control position 12 of each display screen is leaked;

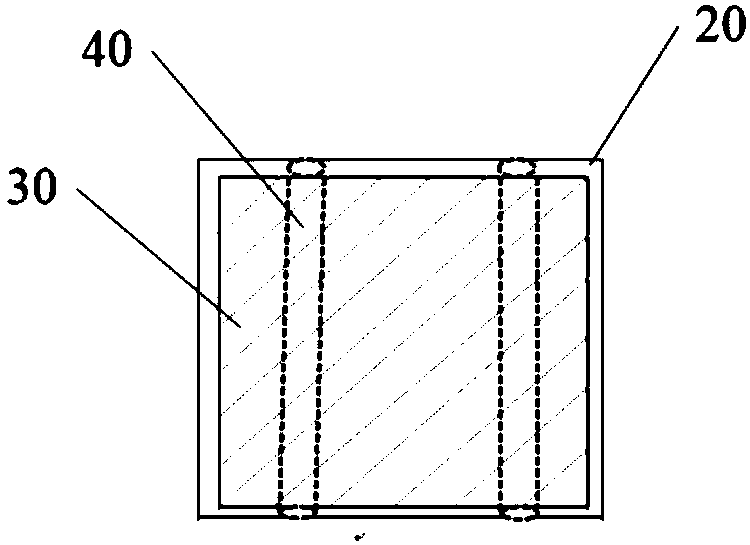

[0026] The large substrate 10 that exposes the IC control position 12 after cutting is placed on the backlight light box or plate 20 with the lower polarizer 30 of the same size or slightly larger than the size of the large substrate 10, such as figure 2 As shown, and light the backlight 40, the other side of the large substrate 10 is equipped with an upper polarizer 50;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com