Plated steel material

A technology of steel and coating, applied in sputtering, ion implantation, superimposed coating and other directions, can solve the problem of insufficient corrosion resistance, and achieve excellent coating adhesion and wear resistance. , Excellent effect of alkali corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0121] Next, the present disclosure will be further described based on examples.

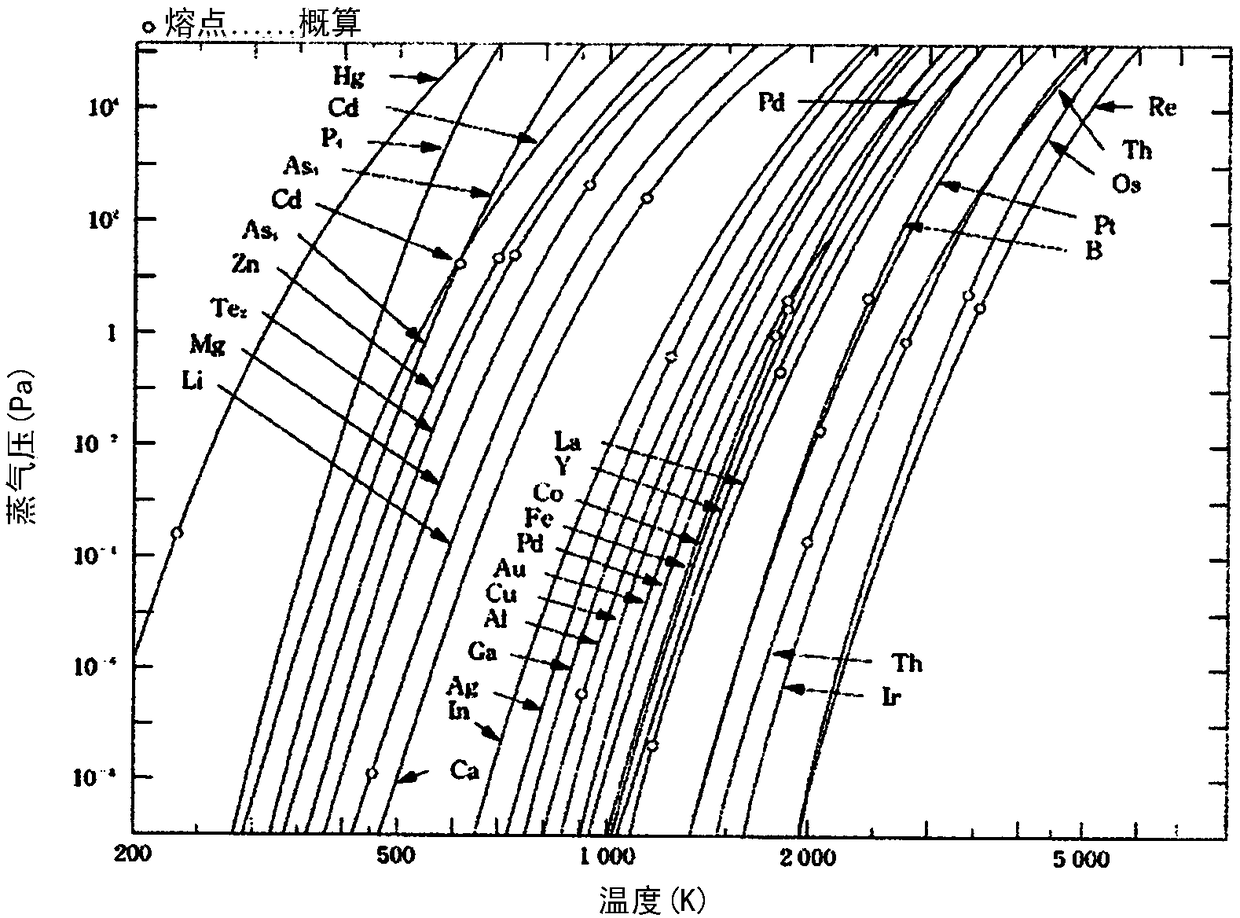

[0122] First, at the time of vapor deposition of the plating layer, the vapor deposition metals (Al, Mg, Zn) placed in the chamber are individually heated by electron beams. Alloys of these elements can also be heated and vapor-deposited, but since these metals have different melting points and vapor pressures, if alloys are used for vapor deposition, it becomes difficult to control the composition distribution of the plating layer with respect to the depth direction , so a separate evaporation source for each element is used. In addition, the vapor deposition conditions are as follows.

[0123] ·Device capacity (chamber capacity): 0.6m 3 ,

[0124] ・The distance from the vapor deposition metal source to the steel plate (substrate): 0.6m,

[0125] ·Vacuum degree in evaporation: 5.0E-3~2.0E-5Pa,

[0126] ・Capacity of crucible for vapor deposition metal source: 40ml, inner diameter:

[012...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com