Electromagnetic injection valve and method for assembling electromagnetic injection valve

An injection valve and electromagnetic technology, which is applied in the field of solenoid fluid injection valves and assembled electromagnetic injection valves, can solve problems such as the cost impact of injection valves, and achieve the effects of improving magnetic properties, reducing total costs, and cost-effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

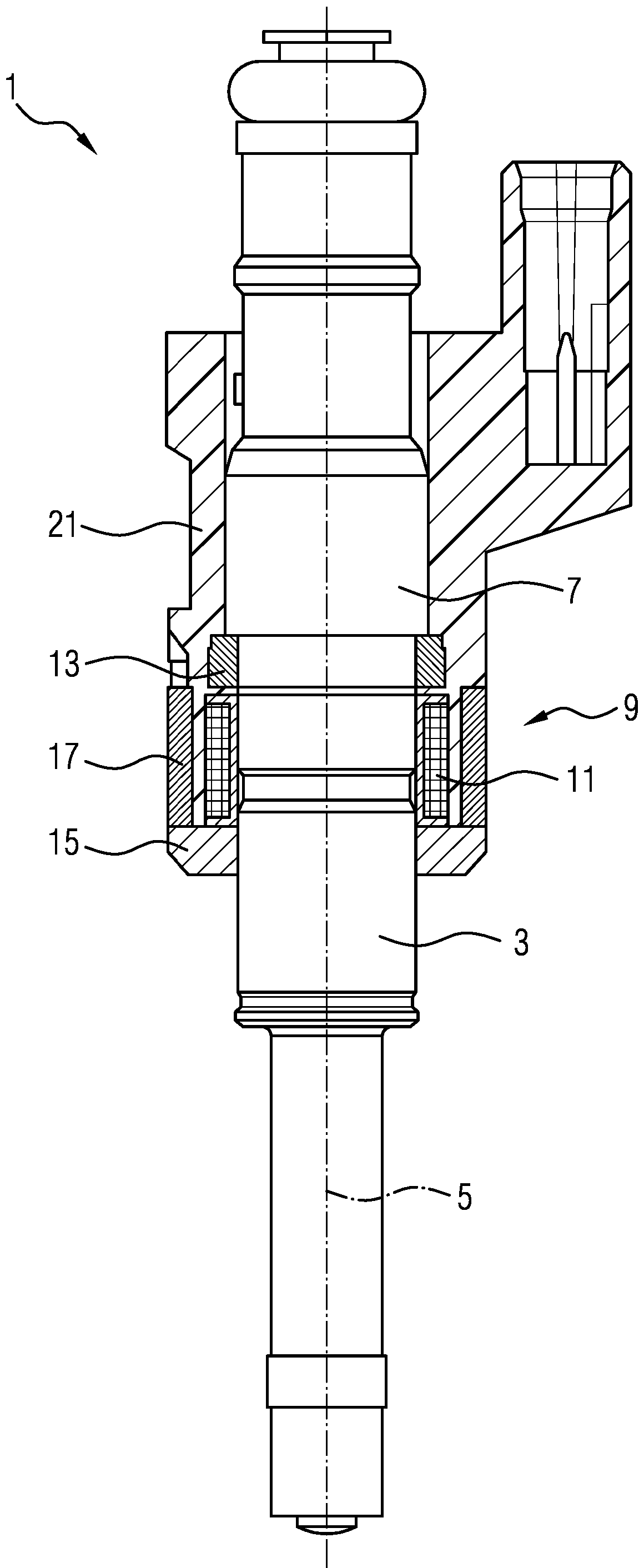

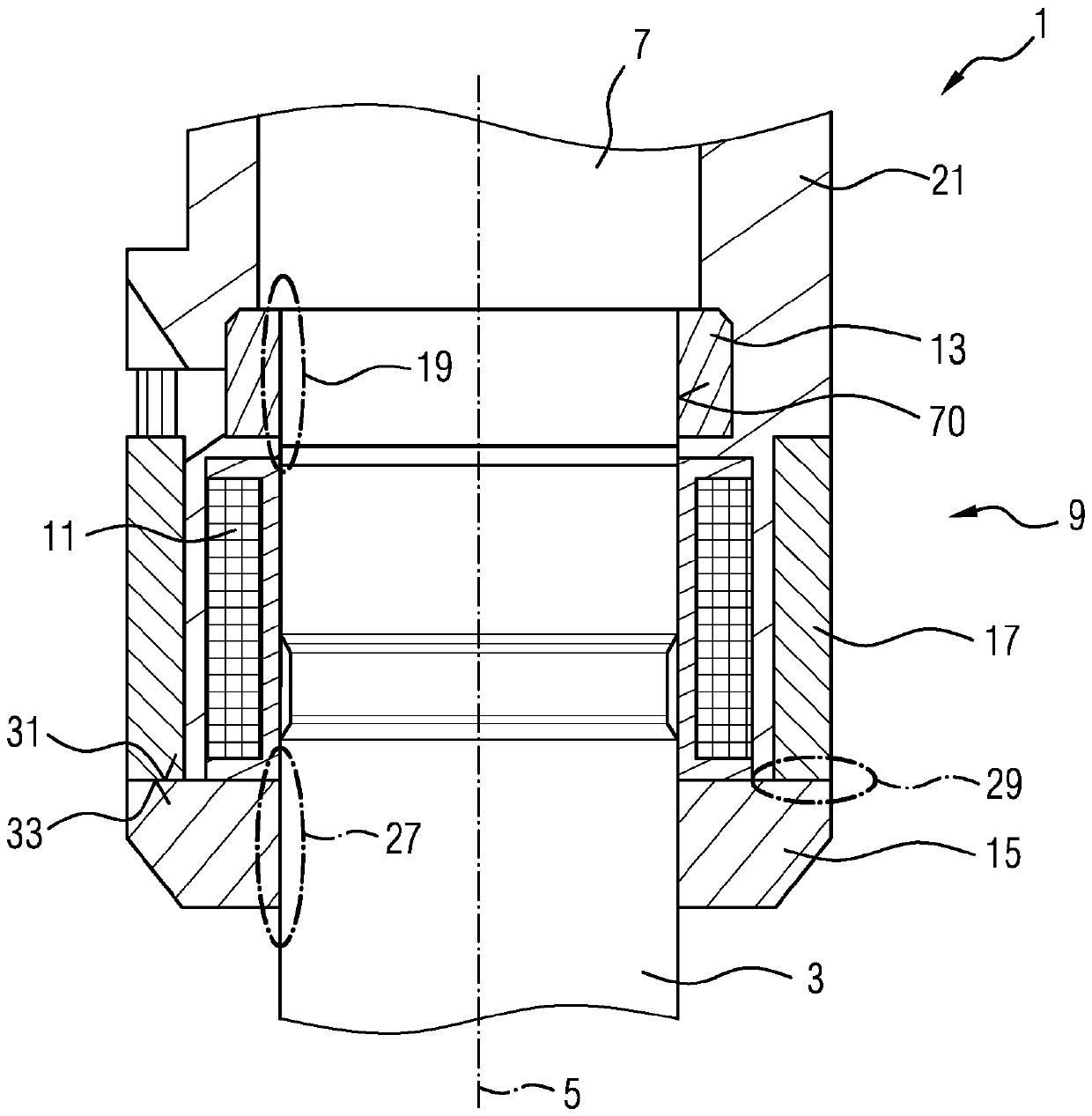

[0038] Figure 1 to Figure 3 The solenoid injector 1 shown is particularly suitable for dosing fuel to an internal combustion engine. However, the invention can also be used with other types of electromagnetic injection valves.

[0039] The injection valve 1 comprises a valve body 3 with a central longitudinal axis 5 and an inlet pipe 7 . The valve body 3 and the inlet pipe 7 form a cavity. The cavity is in figure 1 is not visible in figure 1 The valve body 3 and the inlet pipe 7 are shown only in side view, without sectioning. The cavity has a fluid outlet portion in communication with the fluid inlet portion. A fluid inlet part constituted by the inlet pipe 7 and a fluid outlet part constituted by the valve body 3 are located in particular at opposite axial ends of the injection valve 1 . In the cavity, the valve needle can move axially in order to seal and unseal the fluid outlet portion for controlling the flow of fluid out of the injection valve 1 .

[0040] The in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com