A kind of lithography equipment and lithography system

A technology of lithography equipment and light beams, which is applied in the direction of optomechanical equipment, optics, instruments, etc., can solve the problems of low pattern accuracy, complex alignment steps, and low accuracy, so as to avoid translation steps and alignment steps, The effect of improving accuracy and improving alignment tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention. Obviously, the described embodiments are part of the embodiments of the present invention, not all of them.

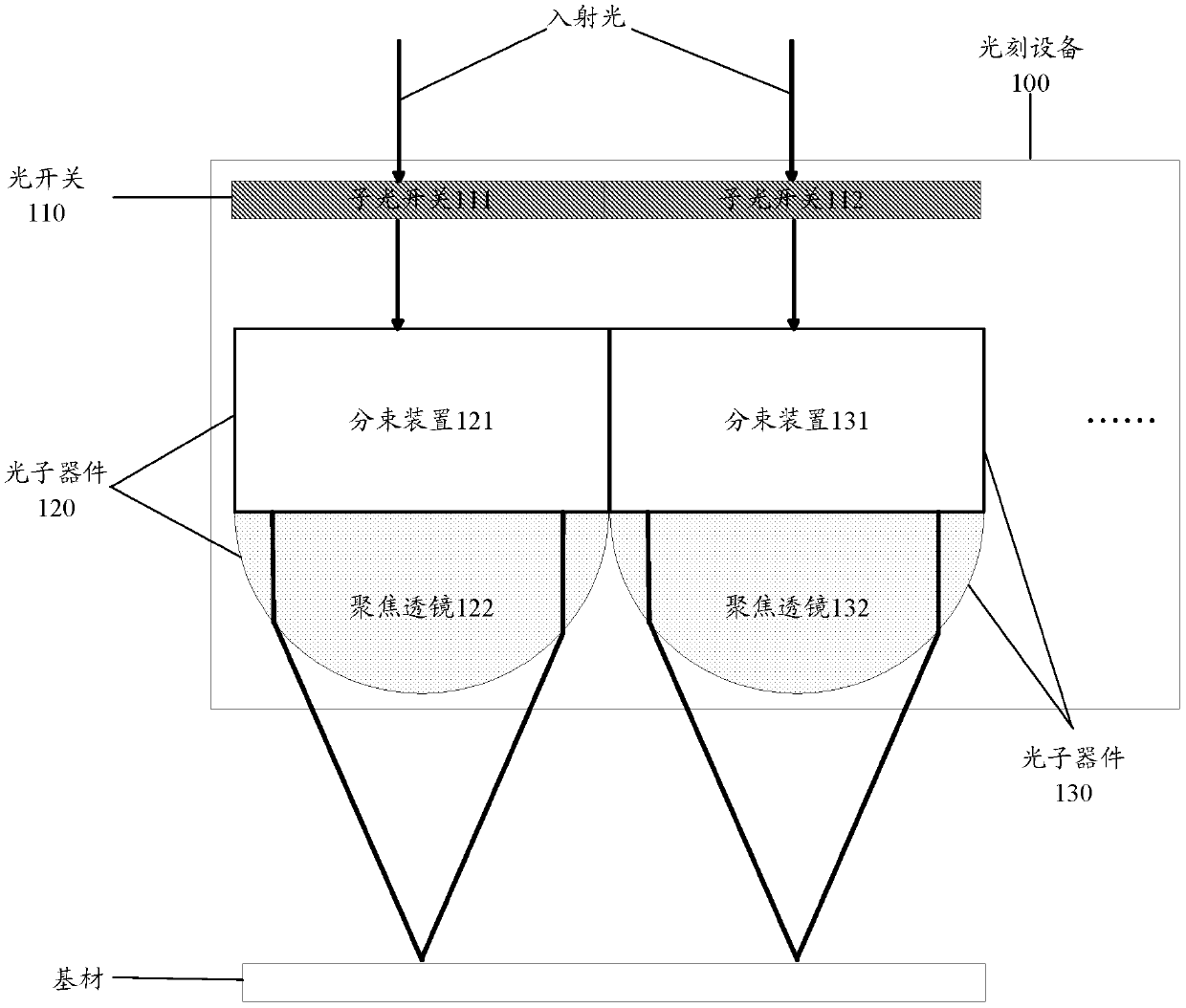

[0036] figure 1 A schematic plan view of a lithographic apparatus 100 according to an embodiment of the present invention is shown. Such as figure 1 As shown, the lithographic apparatus 100 of the embodiment of the present invention includes: an optical switch 110 , a photonic device 120 and a photonic device 130 .

[0037] The optical switch 110 includes a sub-optical switch 111 and a sub-optical switch 112 , the sub-optical switch 111 corresponds to the photonic device 120 , and the sub-optical switch 112 corresponds to the photonic device 130 . Taking the sub-optical switch 111 as an example, the state of the sub-optical switch 111 includes an on state and an off st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com