Making method of ass milk powder capable of preserving nutrient components

A technology of donkey milk powder and complete nutrition, which is applied in the field of preparation of donkey milk powder with preserved nutritional ingredients, which can solve the problems of poor product appearance and solubility, and destruction of active ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

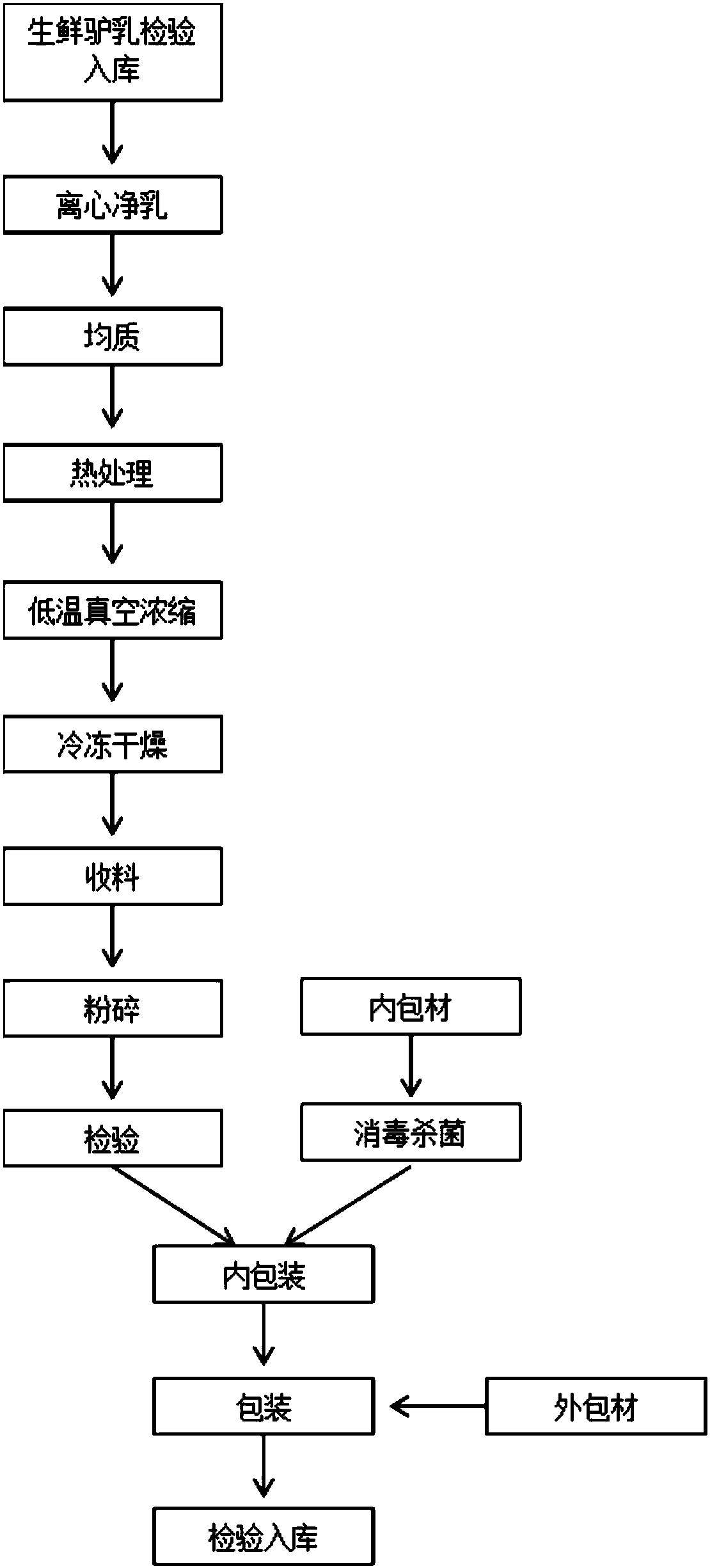

[0021] Such as figure 1 As shown, this implementation provides a production method for preserving the active ingredients and nutrition of donkey milk powder, by performing low-temperature vacuum concentration on raw donkey milk after heat treatment of the raw material milk. Specific steps are as follows:

[0022] (1) Inspection and storage of raw donkey milk: Fresh donkey milk is inspected according to the acceptance standards of donkey milk. After passing the inspection, it is put into storage for production. The acceptance standards are as follows:

[0023] Table 1. Acceptance criteria for sensory indicators of raw donkey milk

[0024]

[0025] Table 2. Acceptance criteria for physical and chemical indicators of raw donkey milk

[0026]

[0027]

[0028] Table 3. Acceptance criteria for the total number of colonies in raw donkey milk

[0029] project

Microbial limit (CFU / mL)

Total number of colonies

≤2*10 5

[0030] The quality of fr...

Embodiment 2

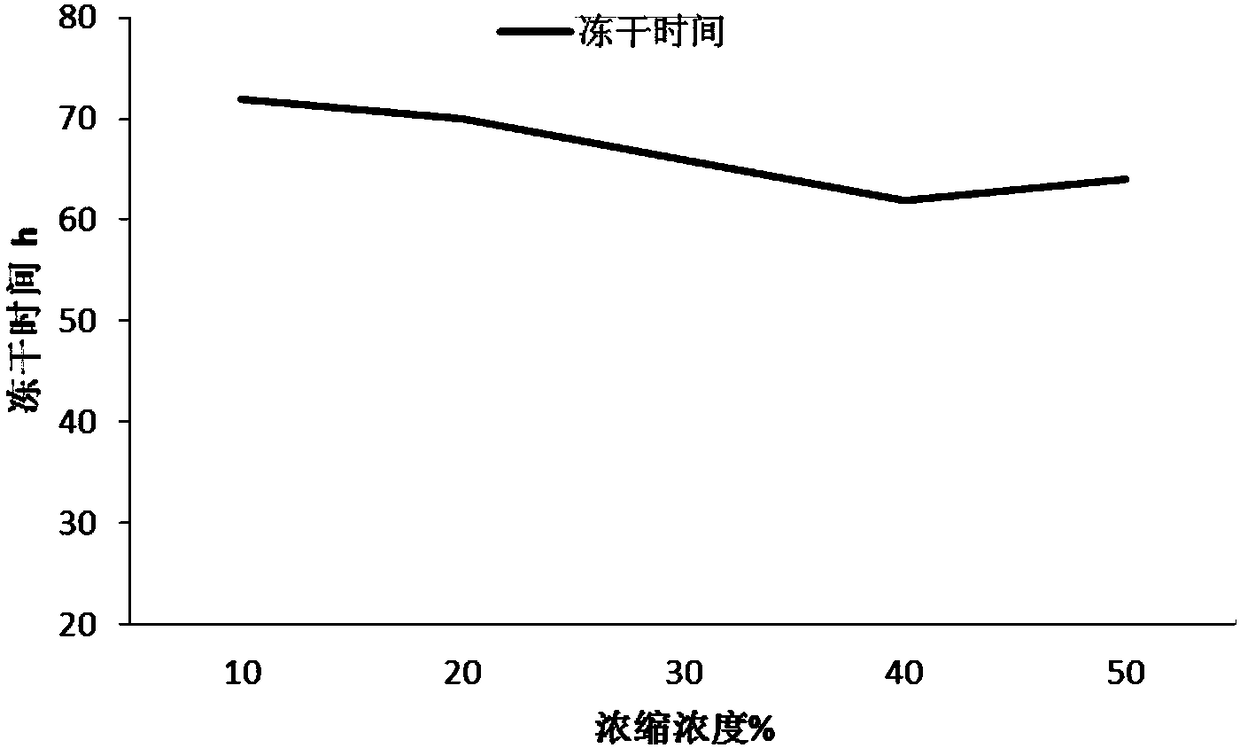

[0051] A preparation method of donkey milk powder with preserved nutritional components, the steps are: firstly carry out clean milk to remove impurities, homogenize treatment and low-temperature pasteurization, then carry out low-temperature vacuum concentration, so that the concentration of mixed donkey milk reaches 40%, and then carry out vacuum Freeze-dry to obtain donkey milk powder.

Embodiment 3

[0053] A preparation method of donkey milk powder with preserved nutritional components, the steps are: firstly carry out clean milk to remove impurities, homogenize treatment and low-temperature pasteurization, then carry out low-temperature vacuum concentration, so that the concentration of mixed donkey milk reaches 40%, and then carry out vacuum freeze-dried to obtain donkey milk powder,

[0054] The cleaning and impurity removal of the milk is as follows: under the conditions of a temperature of 40-50° C. and a vacuum pressure of 0.20 MPa, high-speed separation of fresh donkey milk at 5000 rpm in a centrifuge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com