Device and method used for decocting jam

A jam and boiling pot technology, applied in application, food forming, food science and other directions, can solve the problems of slow jam cooking, uneven heating of materials, difficult temperature control, etc., and achieves preservation of taste, easy temperature control, Fast heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further elaborated below in combination with specific embodiments.

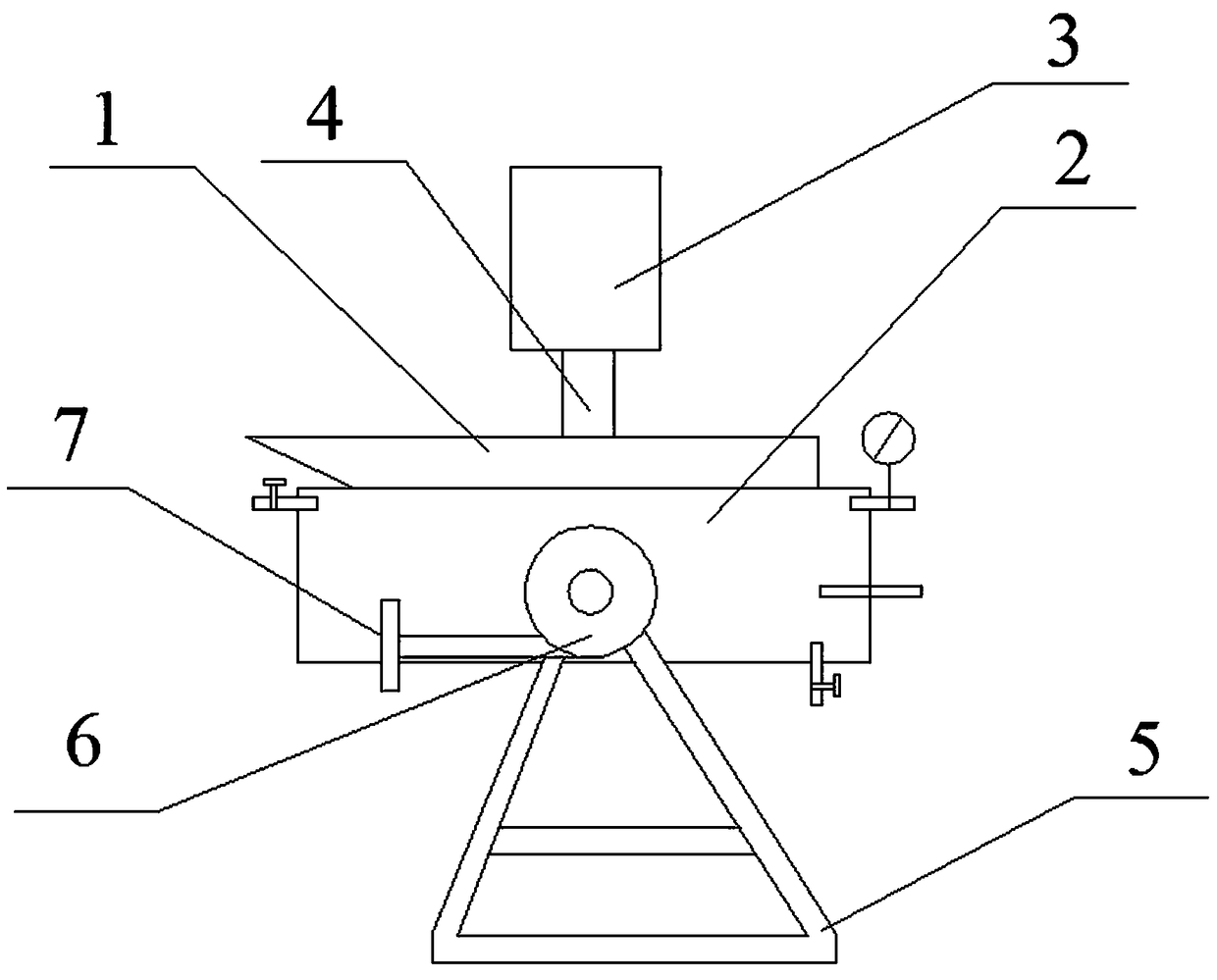

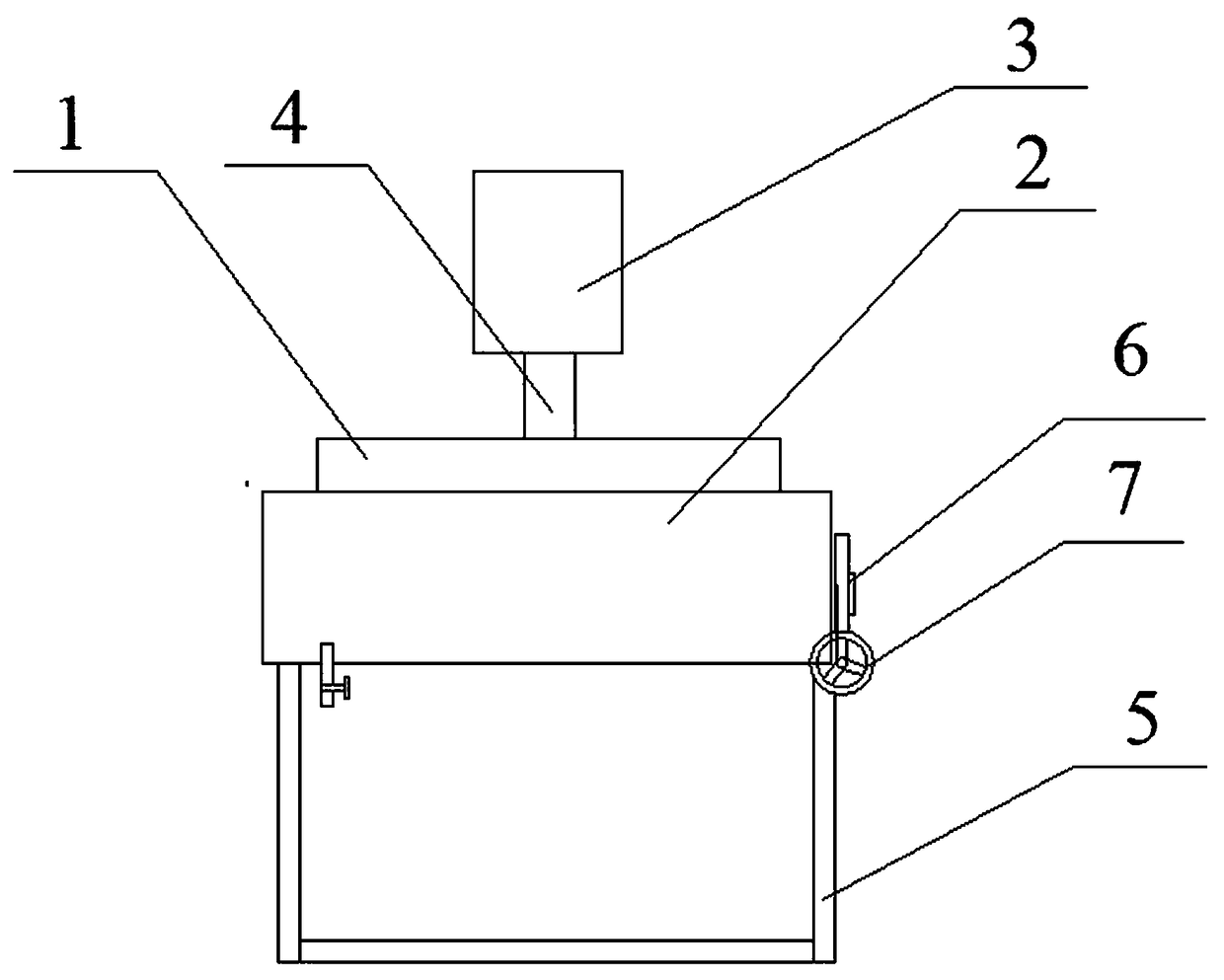

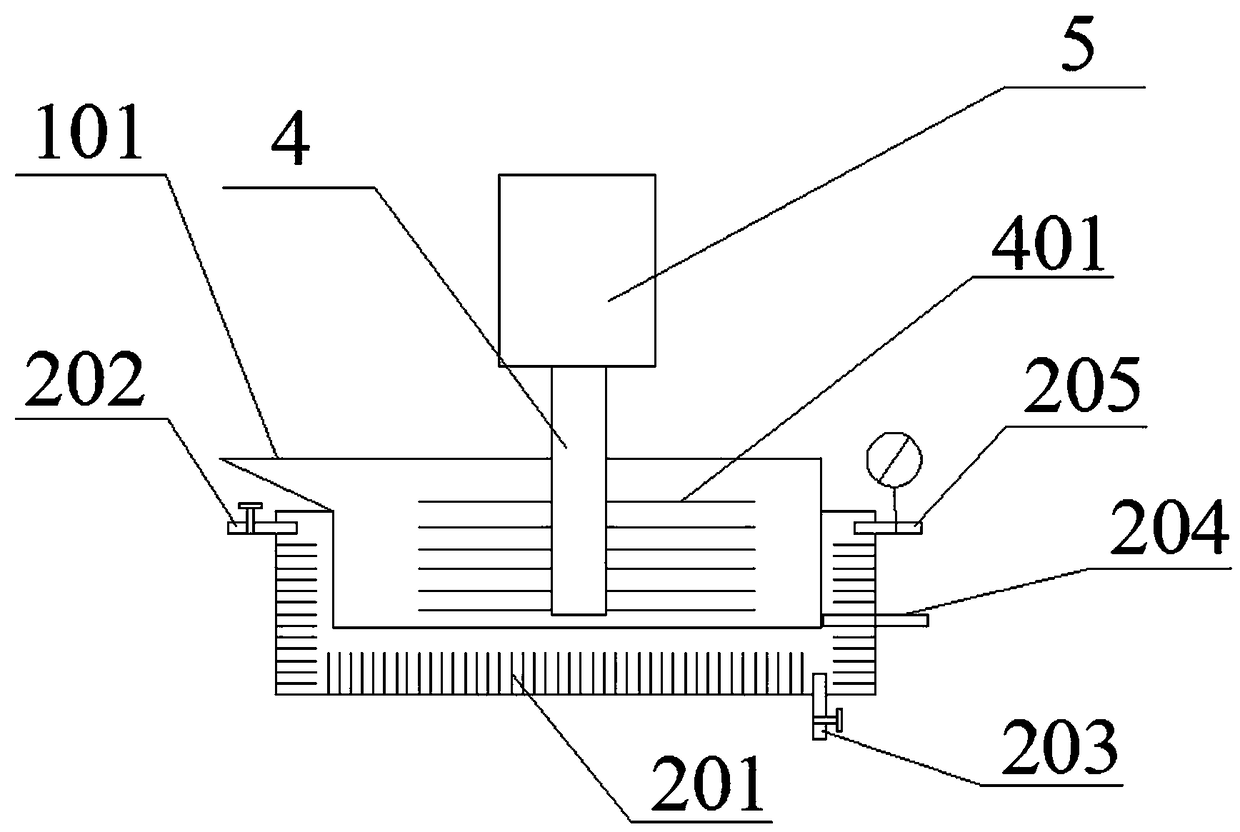

[0023] A device for cooking jam, the device is provided with a cooking pot 1, a heating pot 2, and a stirring mechanism, the heating pot 2 is wrapped and arranged at the bottom of the boiling pot 1, and the stirring mechanism is arranged in the boiling pot 1, The heating pot 2 is wrapped around the bottom of the cooking pot 1 to form a closed cavity, the cavity is provided with a heat-conducting liquid, the cavity is provided with a liquid inlet 202 and a liquid outlet 203, and heating rods 201 are evenly distributed on the inner wall of the cavity , the cavity is also provided with a temperature sensor 204 and a pressure sensor 205; the stirring mechanism is provided with a motor 3 and a stirring shaft 4, and the bottom of the stirring shaft 4 goes deep into the boiling pot 1, and the stirring shaft in the deep cooking pot 1 Stirring rods 401 are evenly distributed outsid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com