Punching machine adopting manipulator to load and unload

A manipulator and punching machine technology, applied in the field of punching machines, can solve the problems of poor equipment operating environment, troublesome metal scrap recycling, and reduced machining accuracy, and achieve the effects of convenient operation, high degree of automation, and improved accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

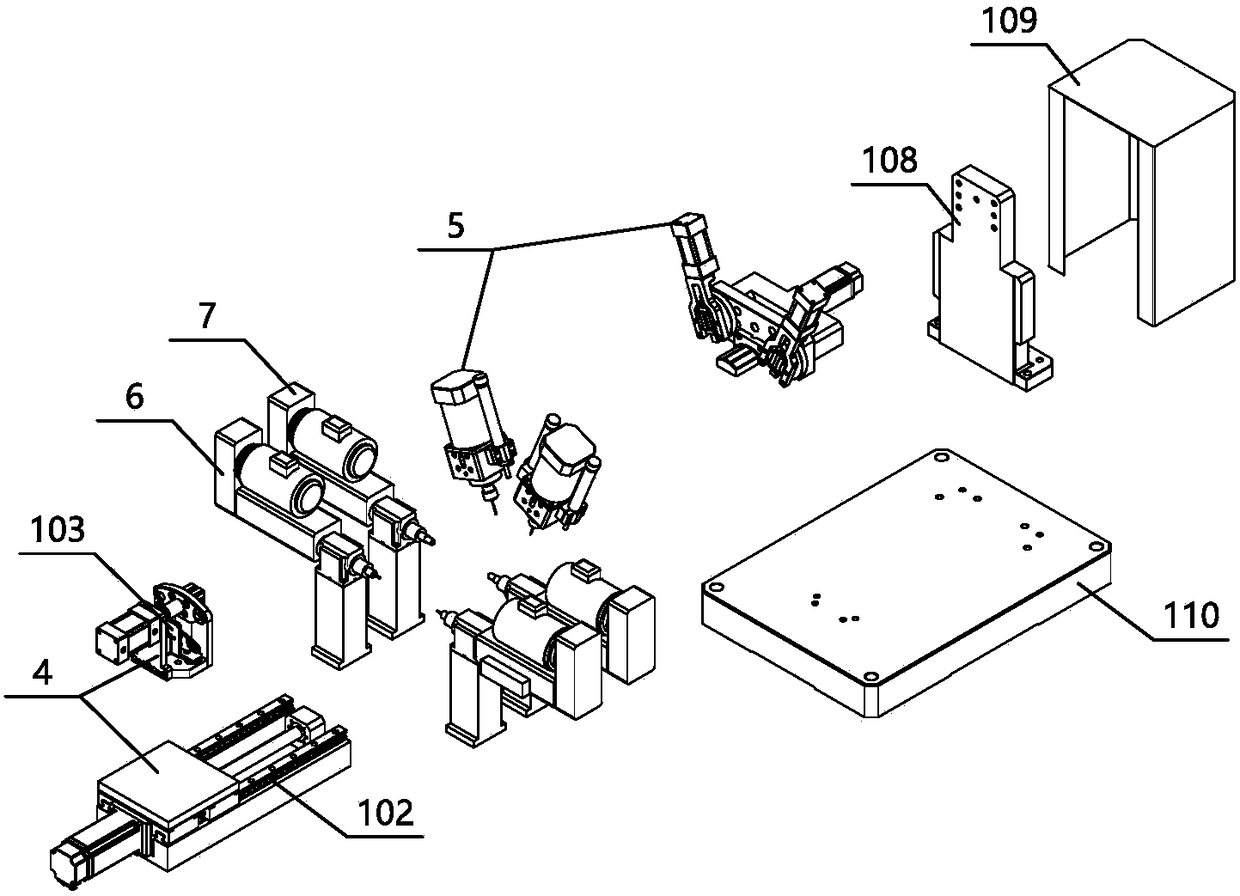

[0026] Attached below Figure 1-9 The present invention is further described.

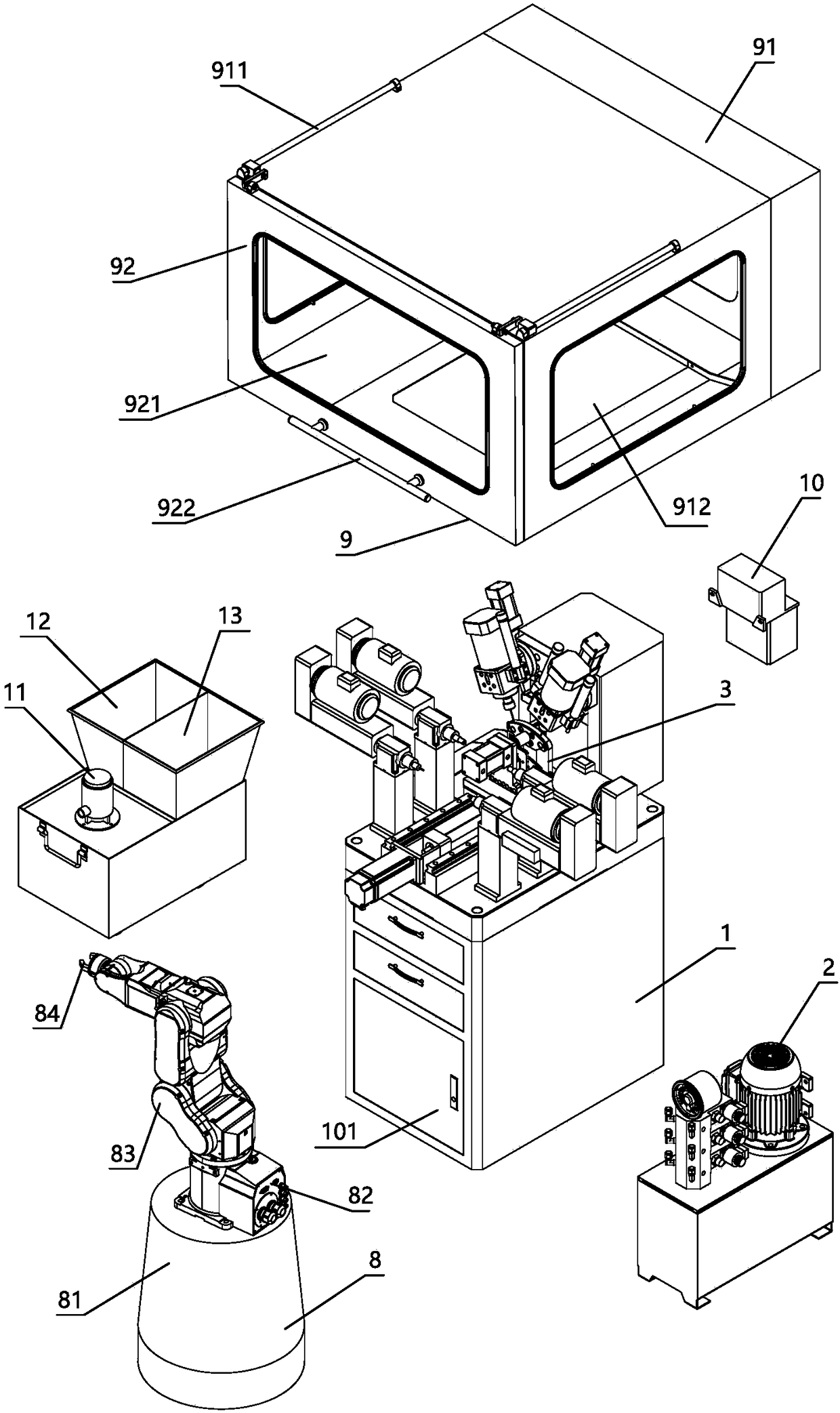

[0027] Such as Figure 1-9 A punching machine that uses a manipulator to load and unload is shown, including a frame 1, a shield device 9, a hydraulic device 2, a controller, a lubrication device 10, a cooling device 11, a processing device 3, a manipulator device 8, and a processing device 3 And the shield device 9 is installed on the frame 1, the shield device 9 covers the processing device inside, and controls the hydraulic device 2, the cooling device 11, the processing device 3 and the manipulator device 8 to operate through the controller.

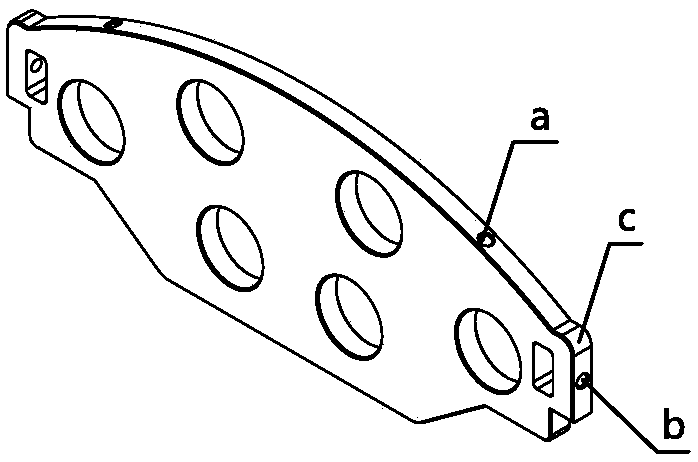

[0028] The connecting plate processed by the punching machine that adopts manipulator loading and unloading of the present invention is the workpiece such as figure 2 As shown, the top needs to be punched with two top connection holes a, and the two side parts need to be punched with tapping holes b at the same position and height, and the two side top...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap