Numerical control machining machine tool special for field machining machine

A technology of CNC machining machine tools and processing machines, applied in the direction of metal processing machinery parts, metal processing equipment, milling machines, etc., can solve problems such as dismantling and transportation conditions, and achieve fast installation and debugging, recovery of shape and position tolerances, and convenience The effect of moving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

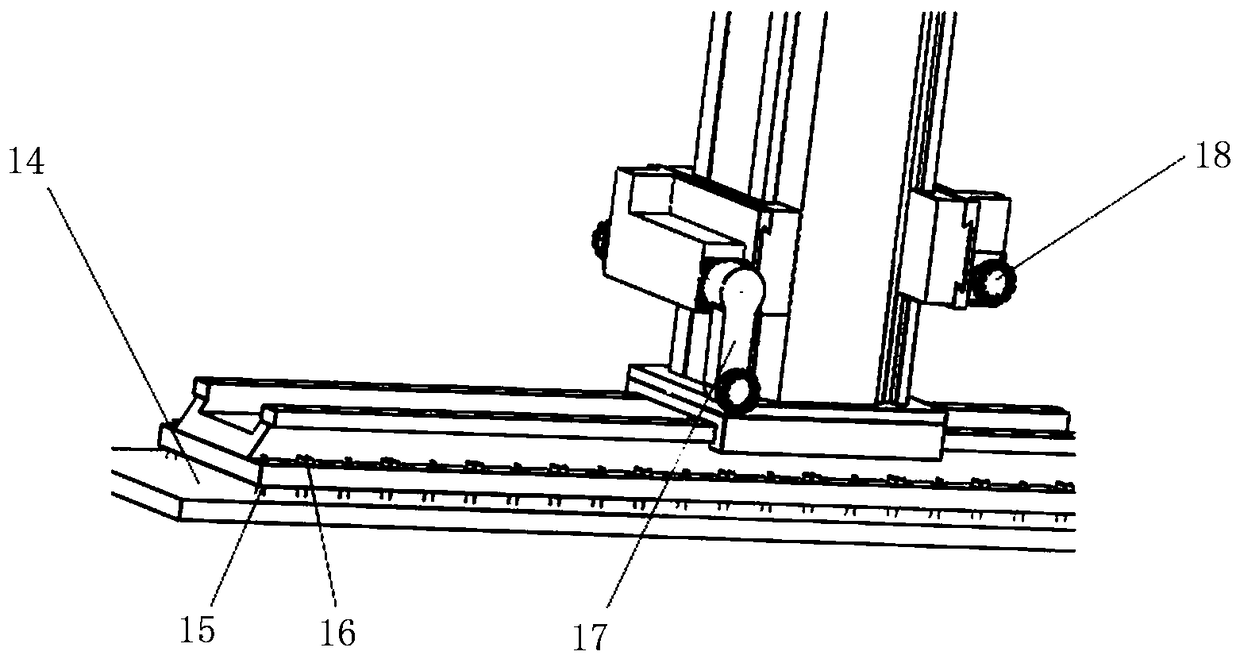

[0010] The present invention includes a steel billet 14, which is characterized in that: a slide rail is fixedly arranged on the steel billet 14, a bed is arranged on the slide rail, a straight milling cutter 18 and a curved milling head 5 are respectively arranged on both sides of the bed, and the bed is also provided with Equipped with level adjustment system.

[0011] As a preferred solution of the present invention, the bed is connected to the steel billet 14 through a drawing wire 16 and a top wire 15 , and the drawing wire 16 and the steel billet 14 are welded together.

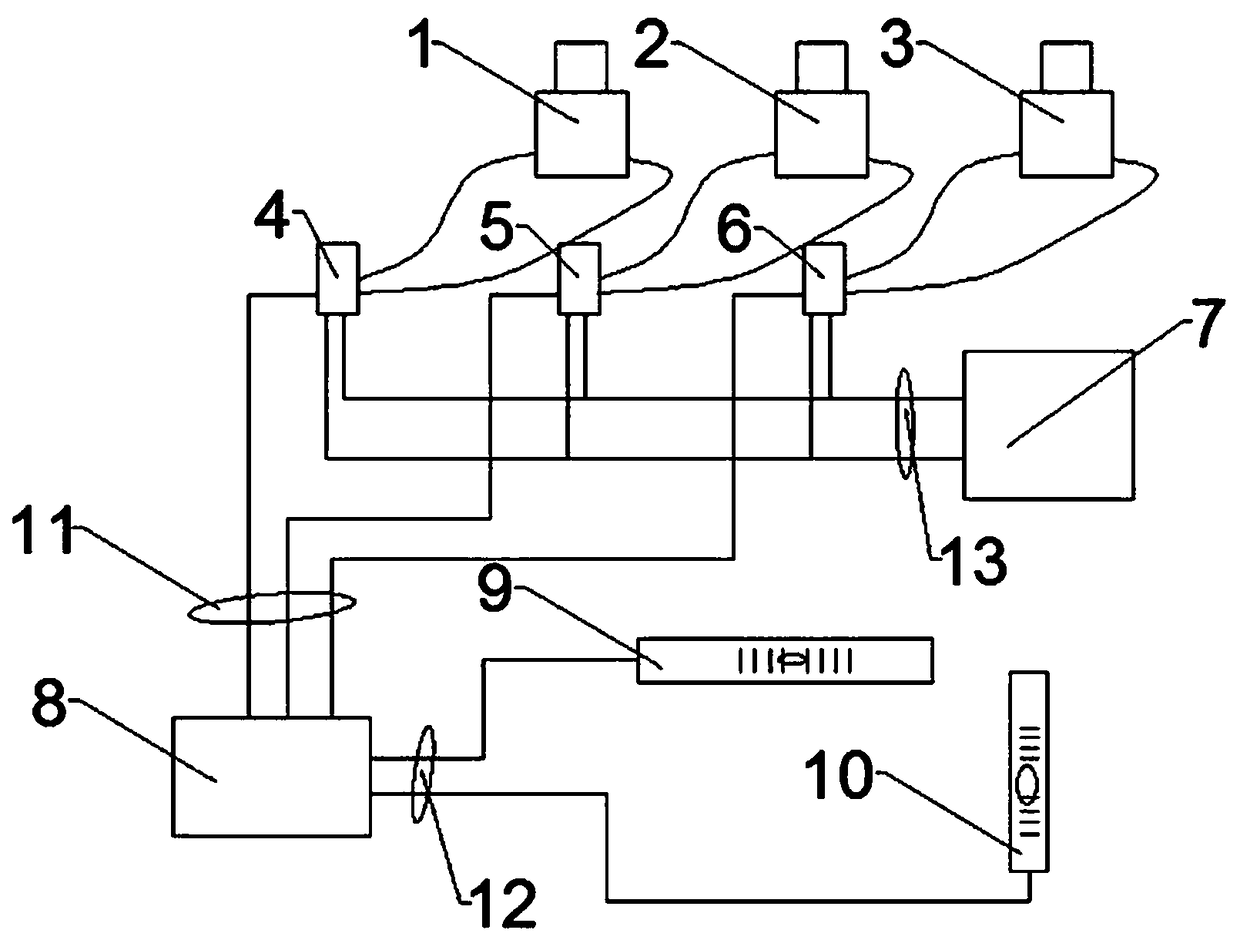

[0012] As another preferred solution of the present invention, the level adjustment system includes a hydraulic pump station 7, and the hydraulic pump station controls the first hydraulic cylinder through the first solenoid valve 4, the second solenoid valve 5 and the third solenoid valve 6 respectively. 1. The second hydraulic cylinder 2 and the third hydraulic cylinder 3; the first solenoid valve 4, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com