Pressure regulating control type arc robot additive forming system

An arc robot and additive forming technology, applied in the field of additive manufacturing, can solve the problems of weak thyristor overcurrent capability, regulation, workpiece scrapping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

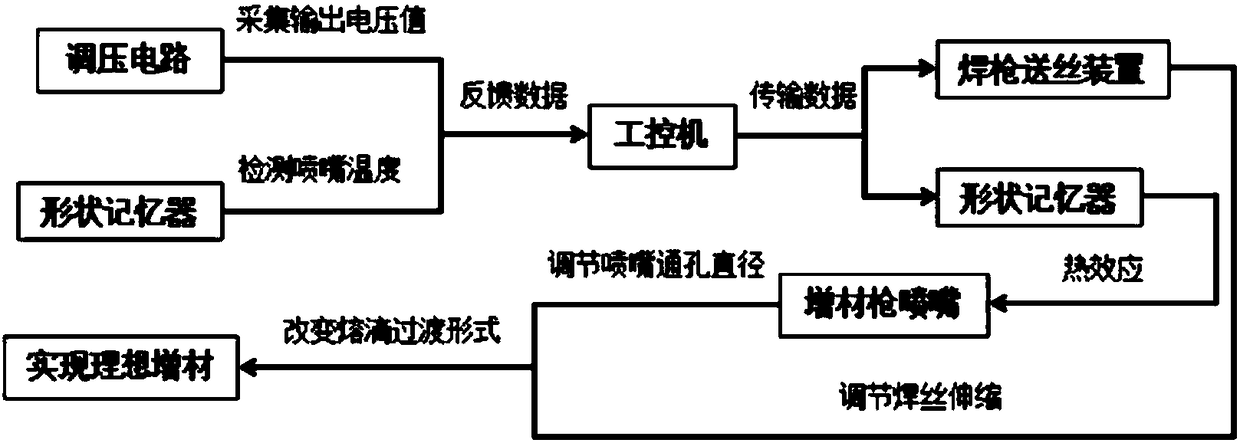

[0027] The voltage regulation control arc additive forming method of the present invention is based on the digital welding technology of MATLAB, an ADLINK embedded Matrix MXC-4002D industrial computer, the industrial computer has been installed with a data processing program based on MATLAB software, and a new Fronius An additive welding torch and its built-in wire feeder, a self-made shape memory device with its built-in temperature sensor, and a set of Advantech USB-4711 data acquisition card.

[0028] combine figure 1 , 2 3. When the additive manufacturing work starts, the preset voltage value of the welding machine is 185V collected through the data acquisition card, and the built-in temperature sensor of the shape memory detects the real-time temperature of the additive gun nozzle at 21°C. After the two sets of data are transmitted to the industrial computer, the The data processing program based on MATLAB software installed in the industrial computer compares the two se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com