Automatic equipment for ring cutting and chamfering of cast pipe

A technology of automation equipment and cast pipe, applied in metal processing equipment, other manufacturing equipment/tools, clamping, etc., can solve problems such as harsh working environment, heavy workload, and personnel injury, and achieve stable rotation process, low cost, The effect of increased automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Although the embodiments of the present invention have been shown and described, those skilled in the art can understand that various changes, modifications and substitutions can be made to these embodiments without departing from the principle and spirit of the present invention. and modifications, the scope of the invention is defined by the appended claims and their equivalents.

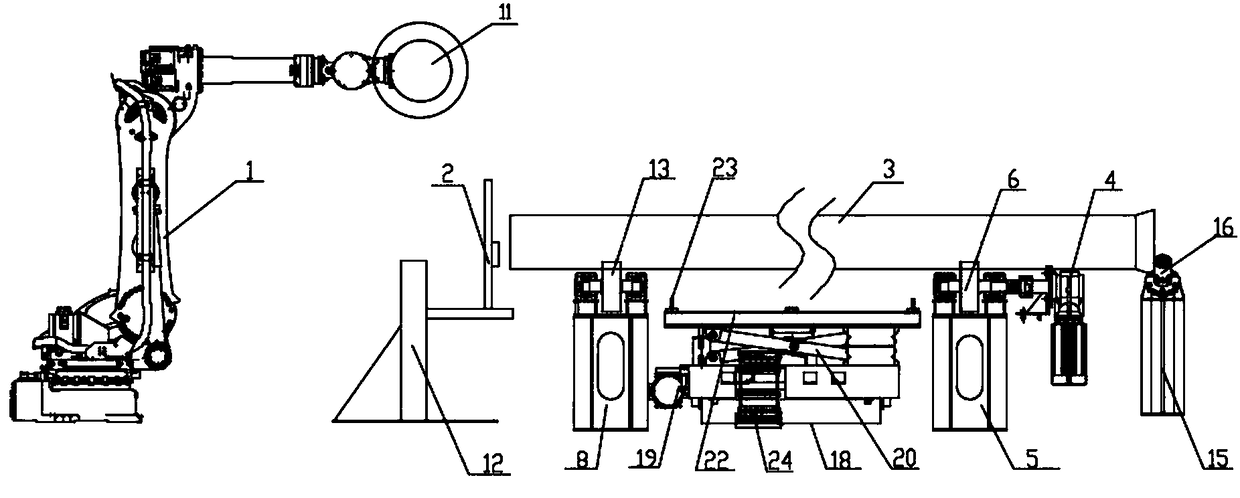

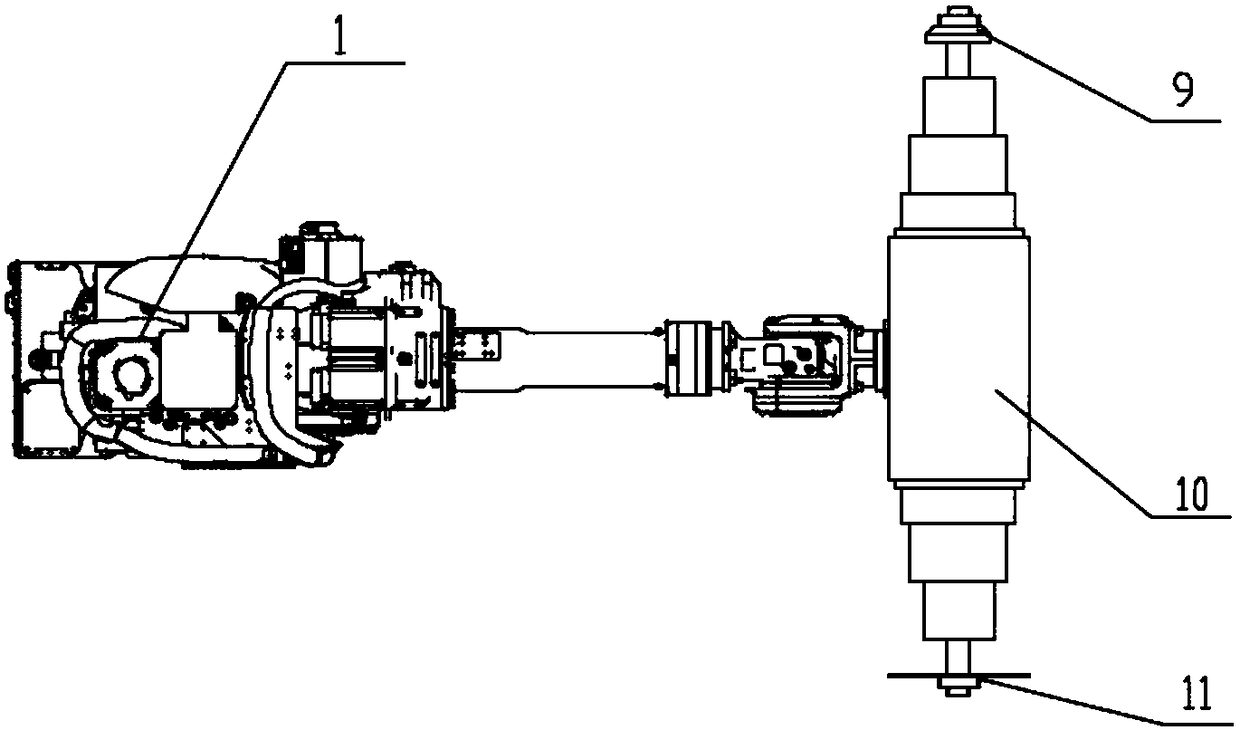

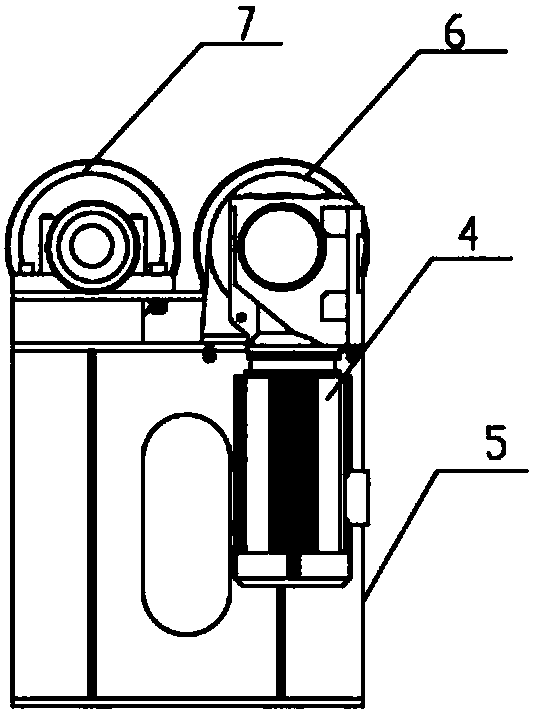

[0021] Such as Figure 1-2 Shown, a kind of automation equipment that is used for cutting ring chamfering of casting pipe, comprises cutting ring chamfering device, casting pipe socket end face detection device, casting pipe supporting device, casting pipe positioning device and controller; Said cutting ring chamfering The device includes a six-degree-of-freedom manipulator 1, a cutting motor 10, a grinding head 9, and a cutting blade 11, the cutting motor 10 is rotationally connected with the T-axis of the six-degree-of-freedom manipulator 1, and output shafts are provided at both ends of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com