Material transferring device for automatic vision detection system of motor commutators

A motor commutator, visual inspection technology, applied in conveyor objects, transportation and packaging, object stacking and other directions, can solve the problems of random defect parts, high labor cost, easy to appear visual fatigue, etc., to improve intelligence , the effect of easy to grasp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below by means of specific embodiments:

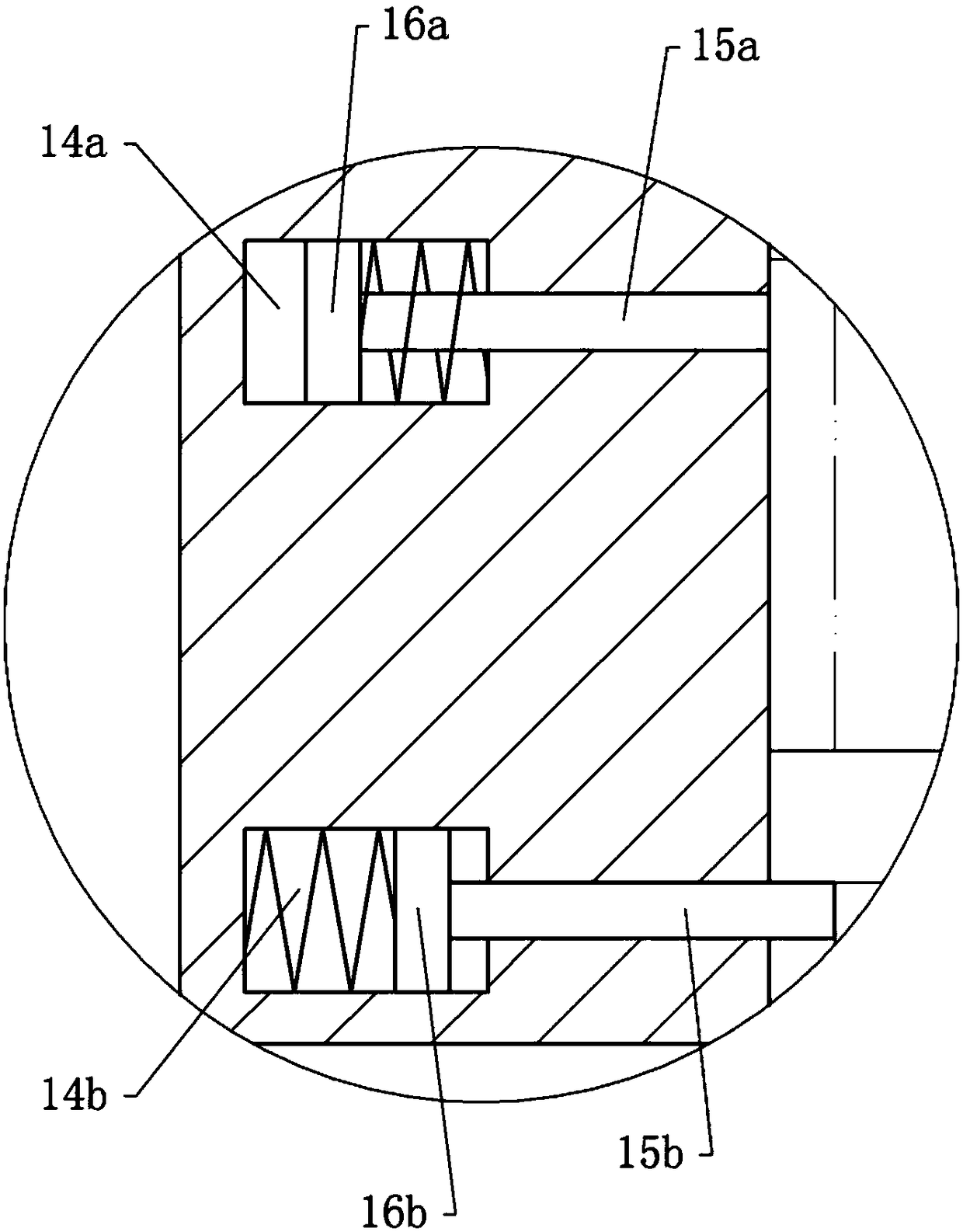

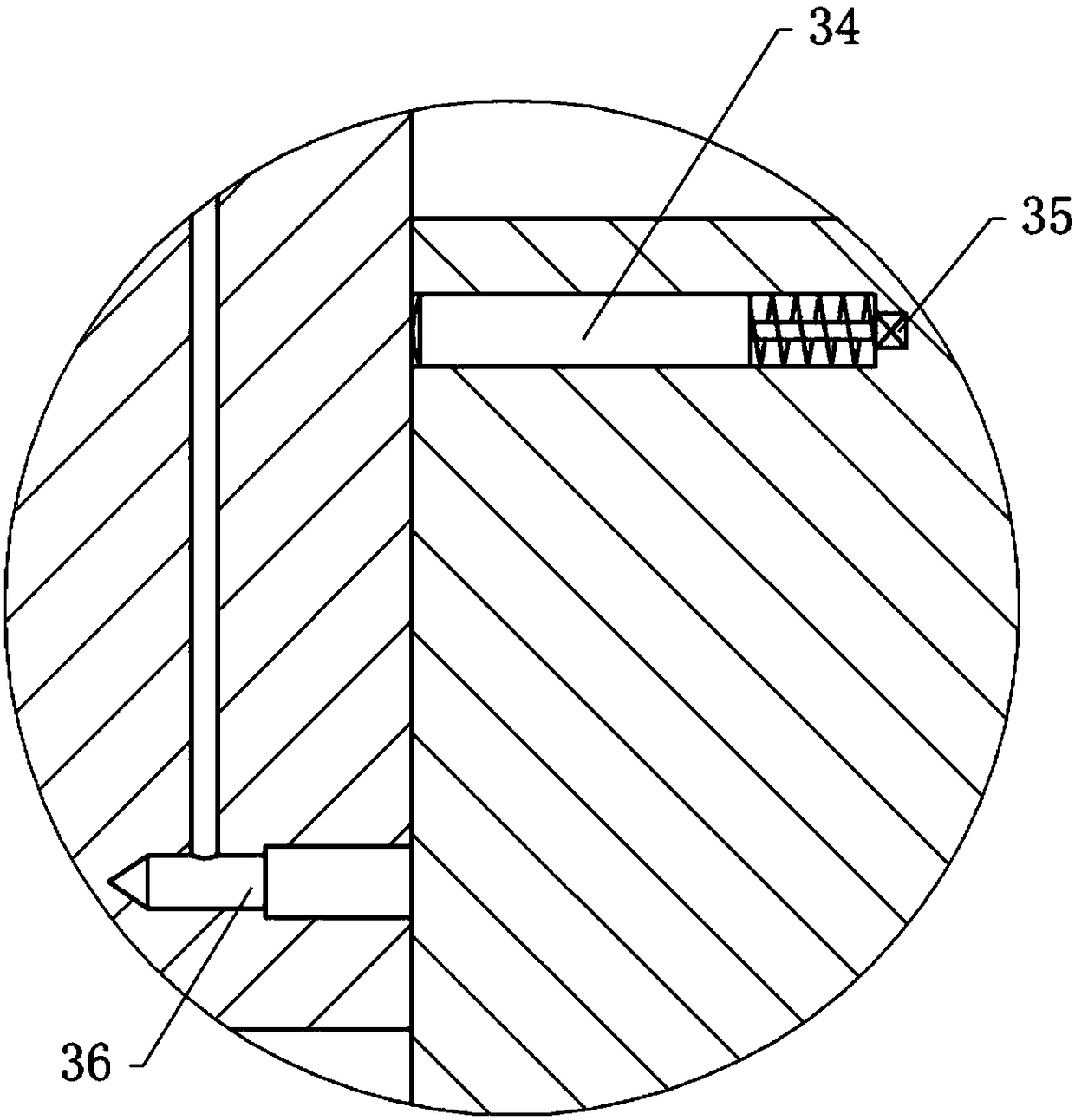

[0027] The reference signs in the drawings of the description include: seat body 10, positioning hole 11, air duct 12, throat 13, first air chamber 14a, first positioning piece 15a, first piston 16a, second air chamber 14b, second Two positioning pieces 15b, second piston 16b, mechanical arm 20, pressure chamber 21, clamping seat 30, pneumatic ejector rod 31, clamping hole 32, protrusion 33, positioning rod 34, pressure switch 35, limit hole 36.

[0028]The material transfer device for the automatic visual detection system of motor commutator in this embodiment includes a frame, a conveyor belt, a positioning part and a transfer part, and the positioning part is provided with the end of the conveyor belt to transfer the commutator to the positioning part for positioning; The part is arranged under the positioning part, so that the transfer part grabs the commutator positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com