Wood flour-filled modified polypropylene material with low odor and imitation flocking effect, and preparation method thereof

A technology of polypropylene material and imitation flocking, which is applied in the field of wood flour-filled modified polypropylene material and its preparation, which can solve the problems of increased cost, reduced production capacity, complicated process, etc., and achieves the reduction of material odor, not easy to separate out, and saving production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

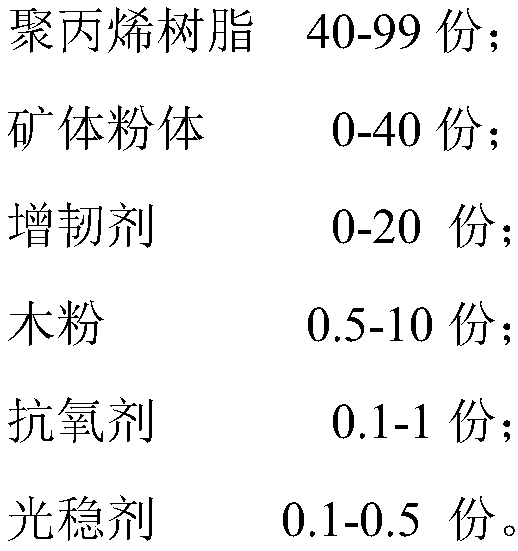

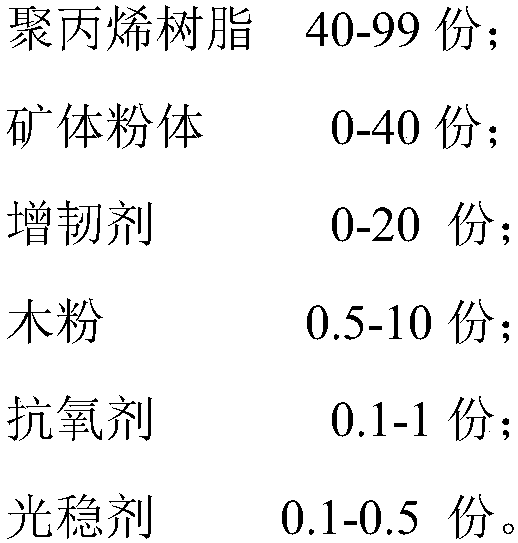

Method used

Image

Examples

Embodiment 1-3 and comparative example 1

[0034] Put the above raw materials into a high-speed mixing machine with a rotation speed of about 800rpm according to the weight percentage shown in Table 1 for 5 minutes, and then put them into a twin-screw extruder. The processing temperature is 200-210°C, and the speed of the main machine is 500rpm. Finally, it can be cooled in a water tank and pelletized by a pelletizer. The obtained modified polypropylene material was injection molded into a textured board to observe the imitation flocking effect on the surface, and the odor and taste type of the material were evaluated according to the standard PV3900 of Volkswagen OEM.

[0035] Table 1 Components and performance test results of wood powder filled modified polypropylene material (component content in the table is percentage by weight)

[0036]

comparative example

Example 1

Example 2

Example 3

polypropylene resin

73.6

73.6

73.6

73.6

talcum powder

20

20

20

20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com