Vertical cloth washing trough

A washing tank and cloth technology, which is applied in the processing of textile materials, processing of textile material carriers, liquid/gas/steam textile material processing, etc. It can solve the problems of limited cloth storage, inability to achieve continuous operation, and short soaking time. Achieve the effects of increasing the fabric holding capacity, better washing effect and prolonging the soaking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

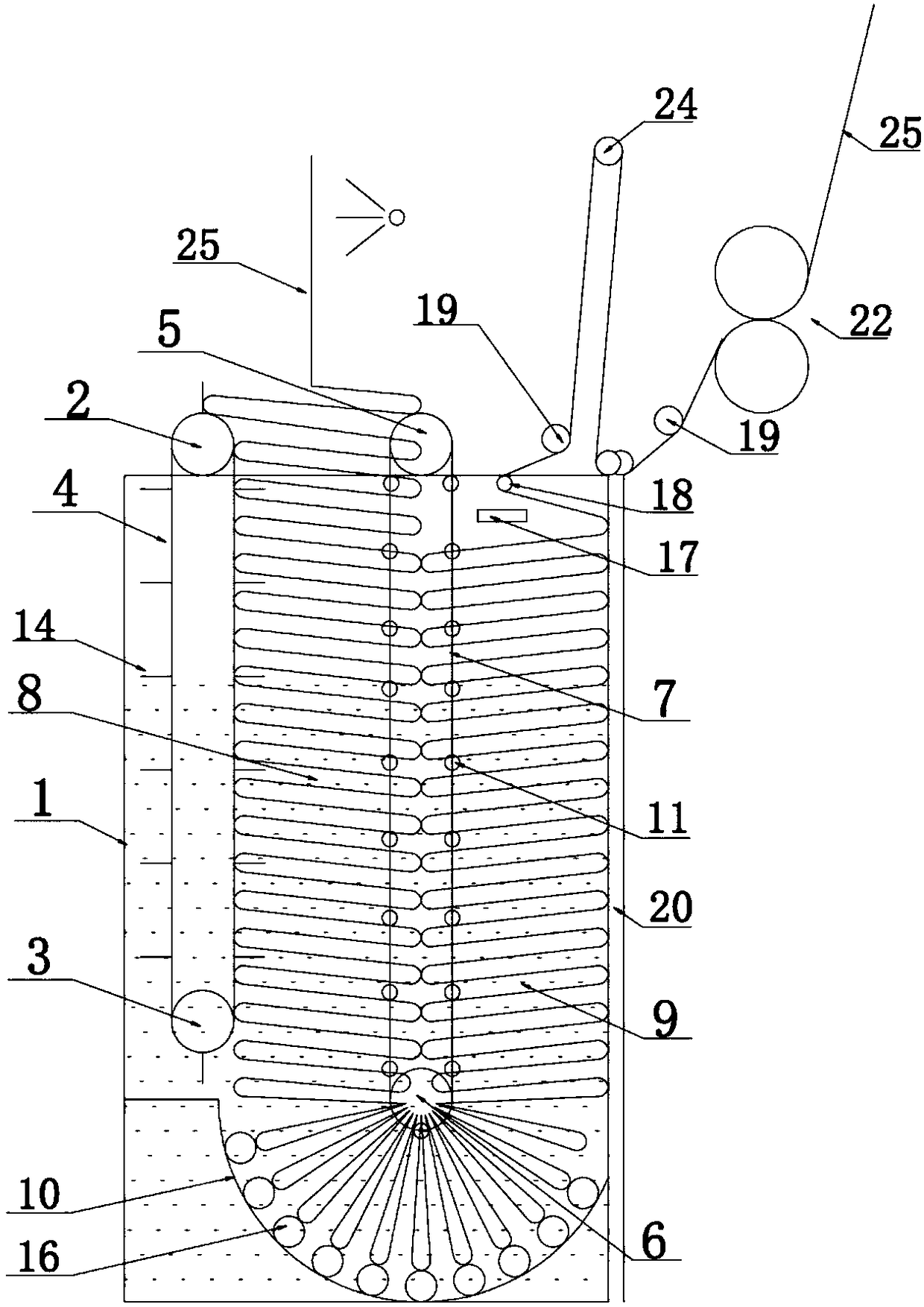

[0045] Example 1, such as Figure 1-Figure 10 As shown, a vertical cloth washing tank includes a rectangular tank with an upper opening, a left conveying mechanism, a right conveying mechanism, and a guide mechanism. The left conveying mechanism is arranged on the left side of the rectangular tank, the left The conveying mechanism includes a left driving roller 2 and a left driven roller 3 arranged in parallel up and down, and a left conveyor belt 4 is surrounded between the left driving roller and the left driven roller;

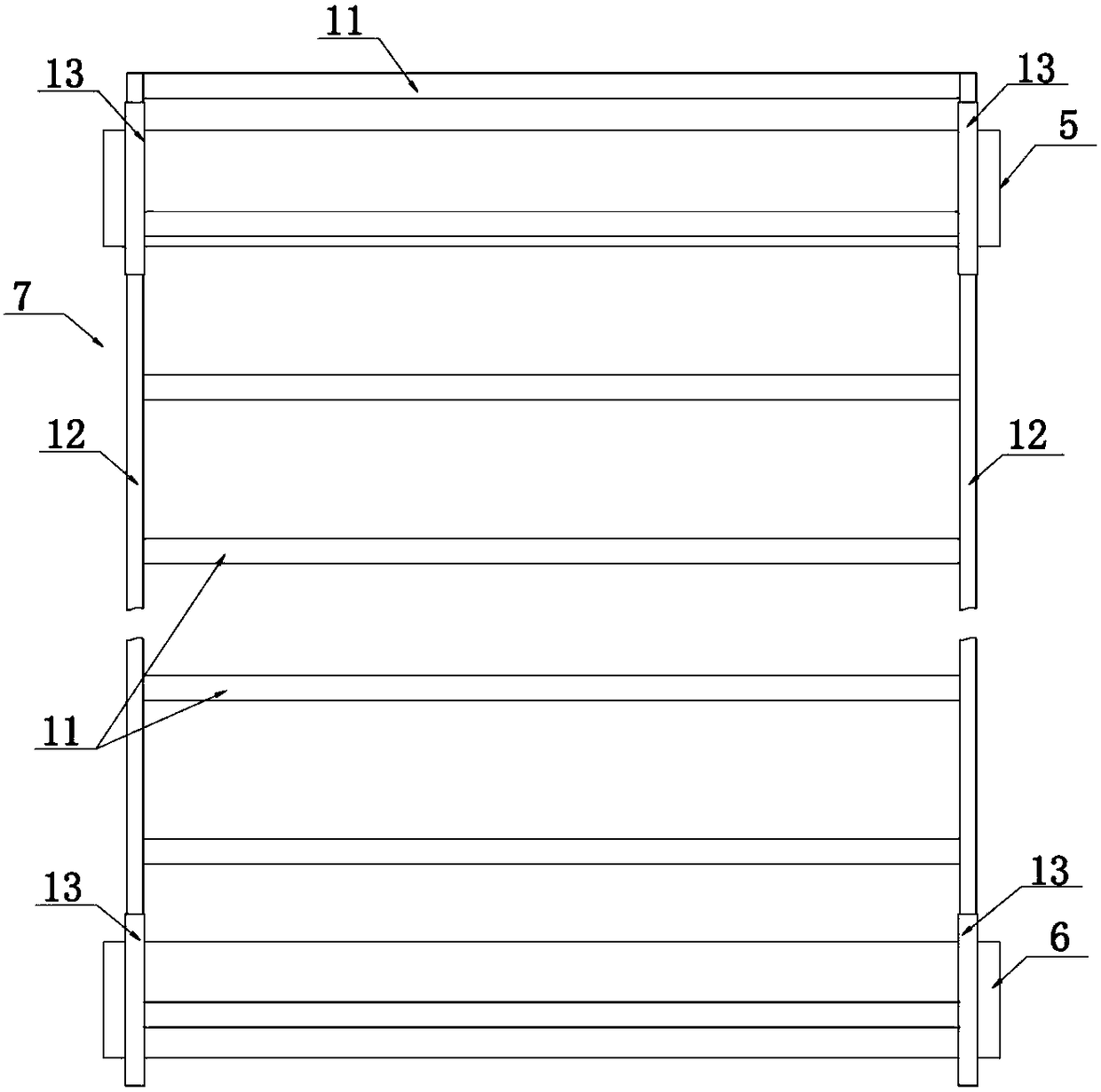

[0046] The right conveying mechanism is arranged on the right side of the center of the rectangular tank. The right conveying mechanism includes a right driving roller 5 and a right driven roller 6 arranged in parallel up and down. The right driving roller and the right follower A right conveyor belt 7 surrounds the moving rollers;

[0047] A material downward channel 8 is formed between the left conveyor belt and the right conveyor belt, and a material upward ...

Embodiment 2

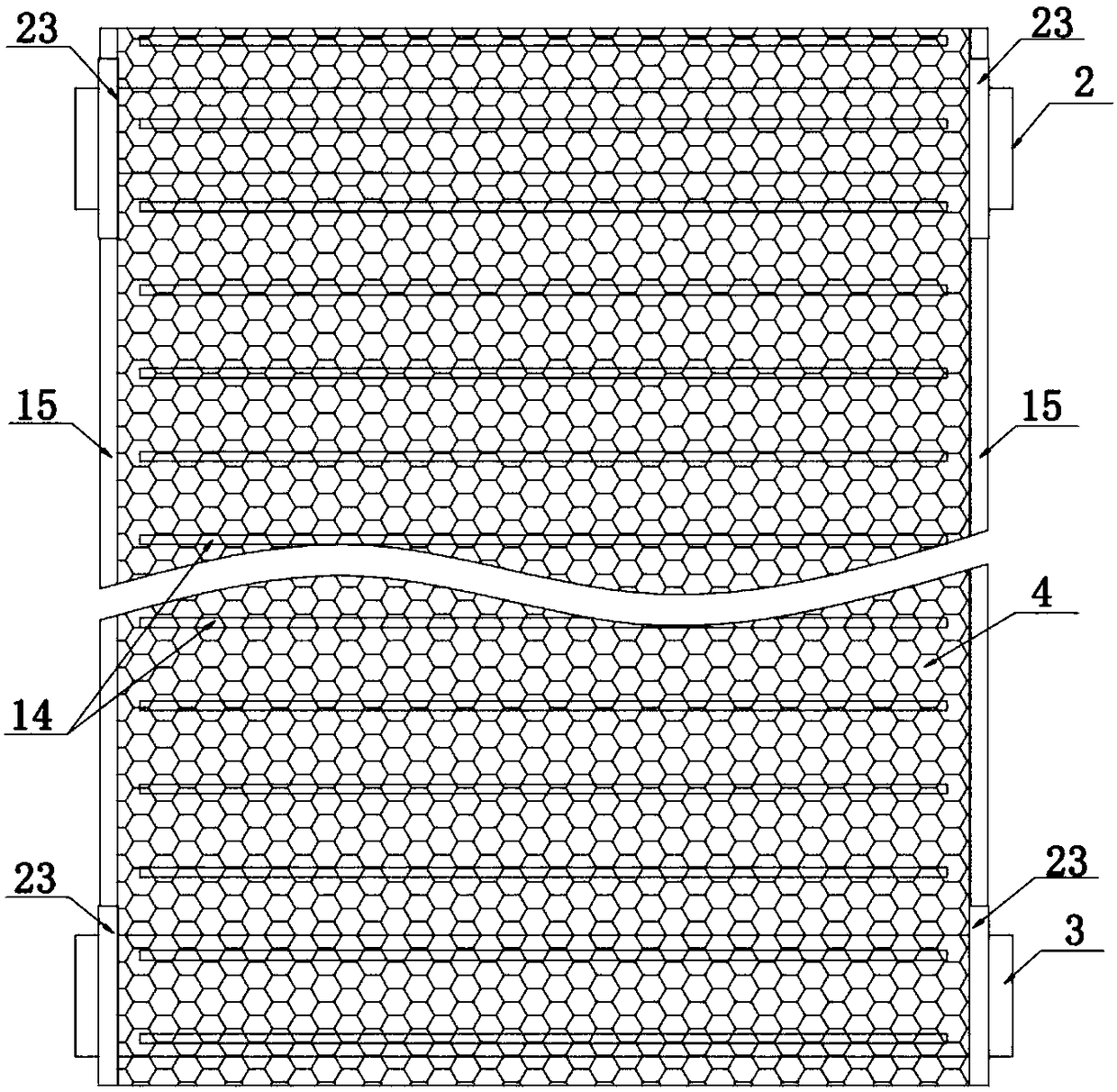

[0062] Example 2, such as Picture 11 with Picture 12 As shown, the left conveyor belt includes at least two circular chains arranged in parallel, and pressure pipes are evenly distributed between the two circular chains; the left driving roller and the left driven roller are provided with Sprocket that matches the chain. The left conveyor belt can also use the same pressure tube design as the right conveyor belt. The longitudinally stacked fabric will enter the space between the pressure tubes on the left and right sides. As the conveyor belt drives the fabric downward, the fabric enters the two Between the side pressure pipes, the horizontal width of the longitudinally laminated fabric increases, and the capacity of the tank body to accommodate the fabric increases, which further increases the amount of fabric storage, extends the immersion time of the fabric in the tank body, and further improves the cleaning effect of the fabric.

[0063] Under the action of the orbiting dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com