Napping, dyeing and finishing process for orange segment-shaped polyester-nylon composite fiber fabrics and splitting agent thereof

A polyester-nylon composite fiber and polyester-nylon composite technology, which is applied in the direction of fiber type, fiber treatment, dyeing method, etc., can solve the problems of longer process flow, damaged fabric strength, weak binding force, etc., to shorten the dyeing process, The effect that the balance strength is damaged and the strength influence is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A cashmere-like dyeing and finishing process for orange petal-shaped polyester / nylon composite fiber fabrics, comprising the following steps:

[0049] (1) Open width refining

[0050] Wash and refine the polyester-nylon composite gray cloth with an open-width washing machine. The temperatures of the six washing tanks are 55°C, 65°C, 80°C, 95°C, 80°C and 40°C.

[0051] (2) Pre-shrinking - initial fiber opening

[0052] Add water, Yuzhongbao and the washed and refined polyester-nylon composite cloth in turn to the dyeing machine vat and run for 5 minutes, then add alkali weight reduction accelerator, oligomer remover and liquid caustic in turn, at 2°C / Raise the temperature to 100°C at a speed of 1 min and keep it warm for 30 minutes, then cool it down to 60°C at a speed of 2°C / min to drain the liquid; for the first time when entering clean water, raise the temperature to 80°C at a speed of 2°C / min and hold it for 10 minutes, then Cool down to 60°C at a rate of 2°C / min ...

Embodiment 2

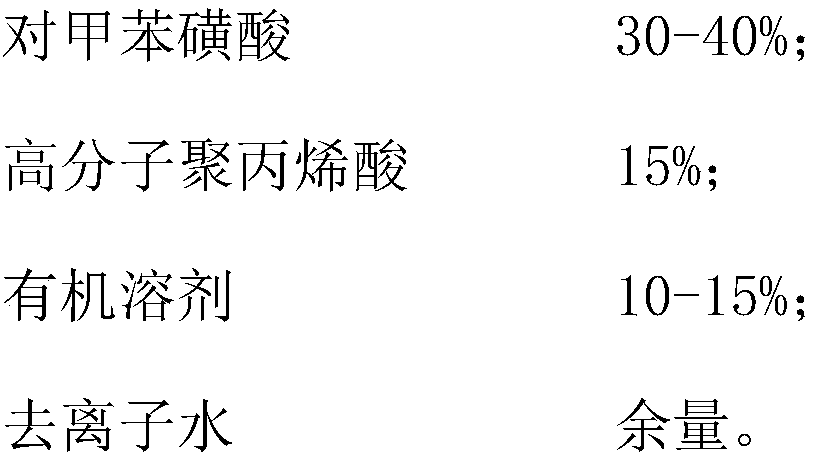

[0075] According to the velvet-like dyeing and finishing process of the polyester / nylon composite fiber fabric of embodiment 1, the difference from embodiment 1 lies in the composition of the fiber opener, and the fiber opener is composed of the following components in mass percentage:

[0076]

[0077]

Embodiment 3

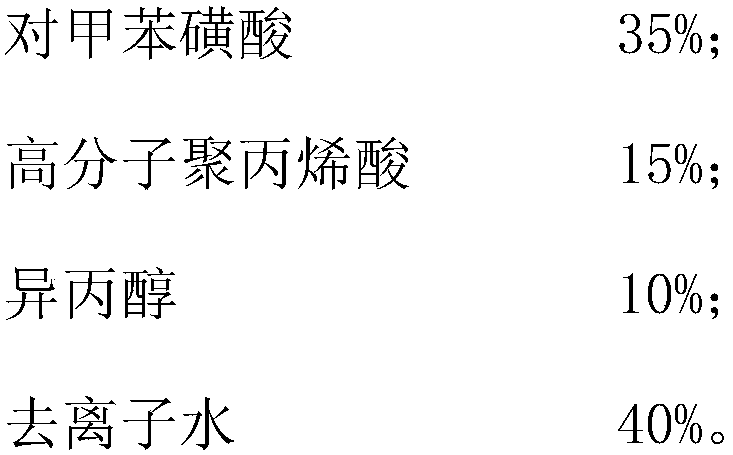

[0079] According to the velvet-like dyeing and finishing process of the polyester / nylon composite fiber fabric of embodiment 1, the difference from embodiment 1 lies in the composition of the fiber opener, and the fiber opener is composed of the following components in mass percentage:

[0080]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com