Support-free full-bridge segment prefabricating method based on cantilever balanced assembling

A cantilever and segment technology, which is applied in the field of unsupported full-bridge segment prefabrication based on cantilever balance assembly, can solve the problems of long construction period, formwork installation error, difficulty in construction workers, etc. The effect of quality, improving efficiency and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

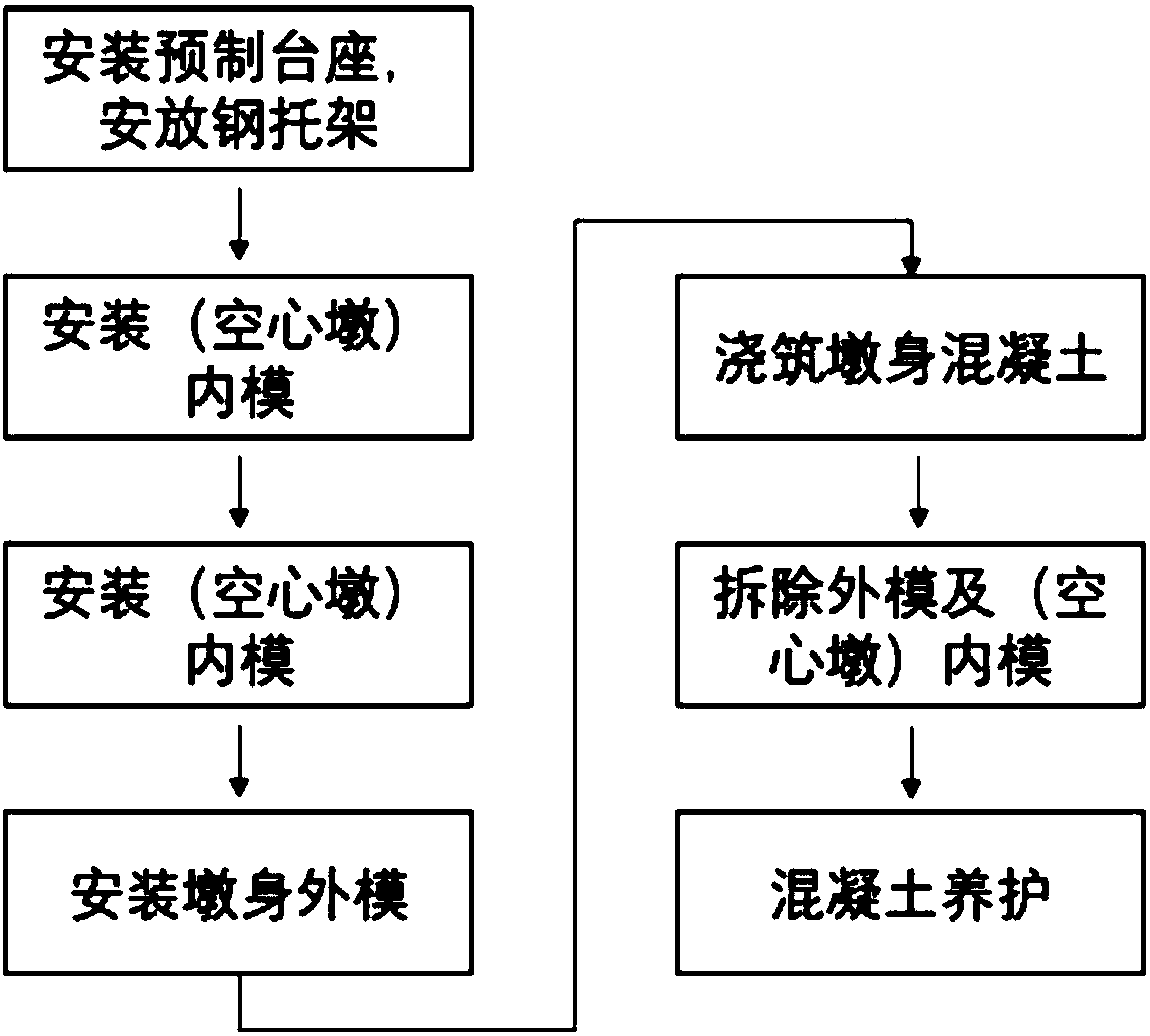

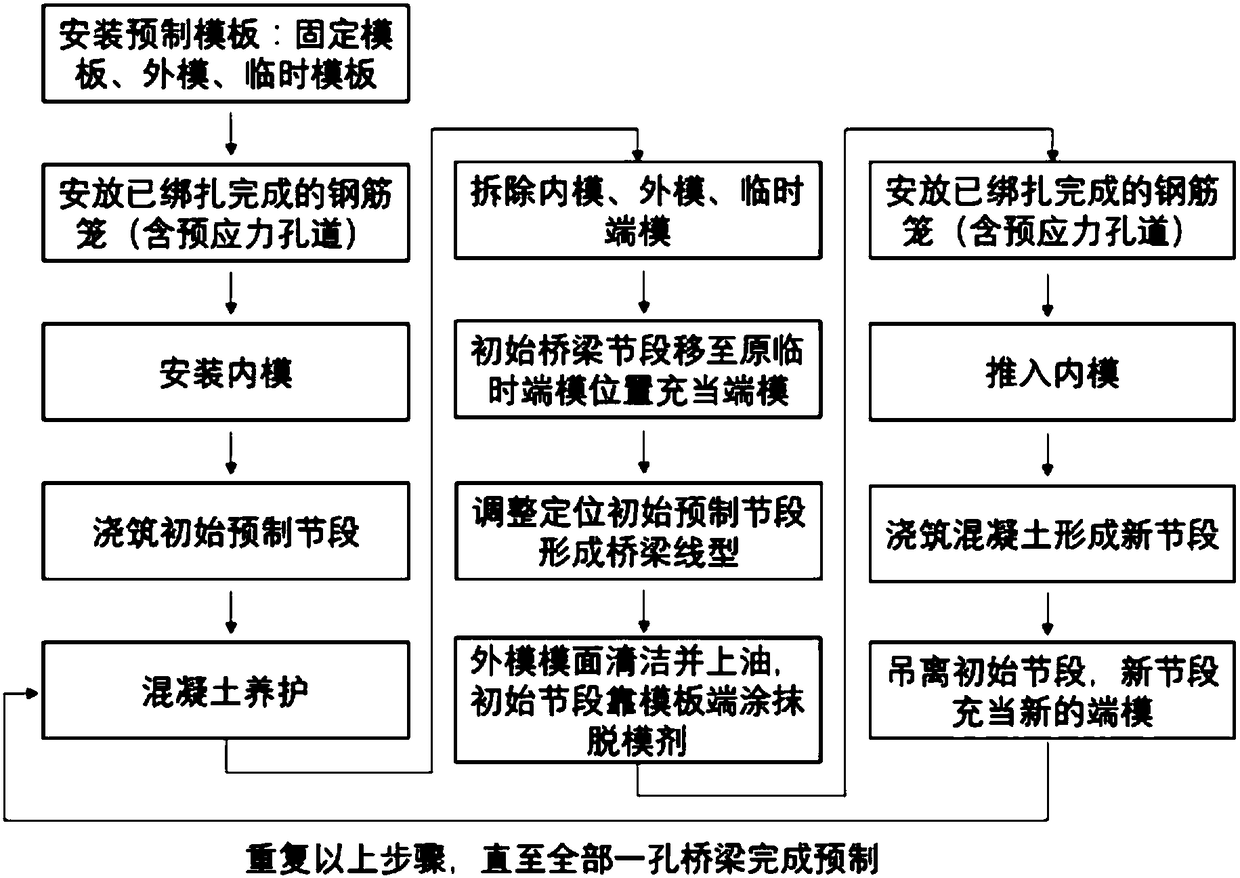

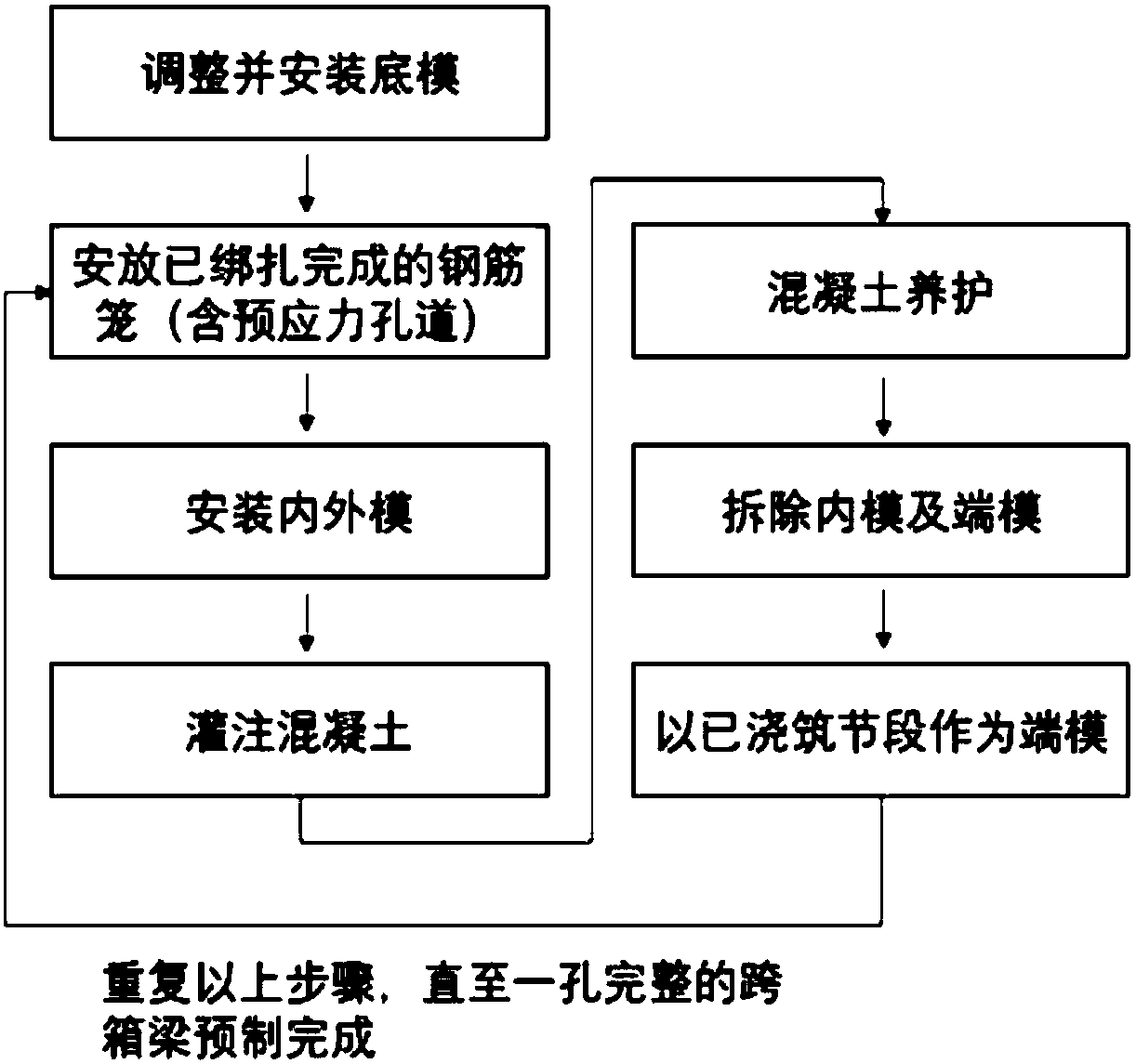

[0043] The present invention adopts the cantilever assembly method and the segmental prefabrication technology to manufacture the unsupported prestressed concrete continuous rigid frame bridge, which mainly includes the following two parts: 1. Prefabrication stage: the beam part is manufactured by the segmental prefabrication technology, and the segmental or integral prefabrication technology is adopted. Manufacture of bridge piers; 2. Assembly stage: first assemble the prefabricated bridge piers; then install the prefabricated sections of the pier top to the top of the pier and consolidate them with the top of the pier; then use the cantilever assembly method to symmetrically assemble section by section along the span direction of the bridge For each section, prestressing is applied to form a whole with the completed parts; finally, after the cantilever is assembled to the mid-span, it is closed with post-cast concrete, and the continuous prestress is stretched after closing to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com