Automatic debugging and correcting system and method of light-splitting path for X-ray fluorescence spectrometer

A fluorescence spectrometer and automatic debugging technology, applied in the field of X-ray fluorescence spectrometer, can solve the problems of inability to guarantee accuracy, X-ray source loss, time-consuming and labor-consuming, etc., and achieve the effect of improving debugging accuracy, high real-time performance, and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention is further described below in conjunction with embodiment.

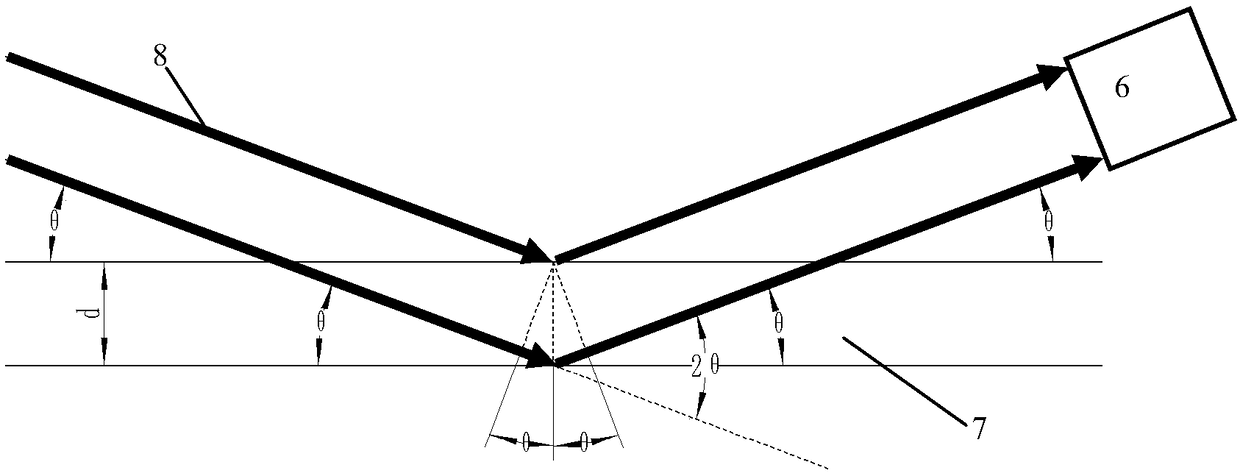

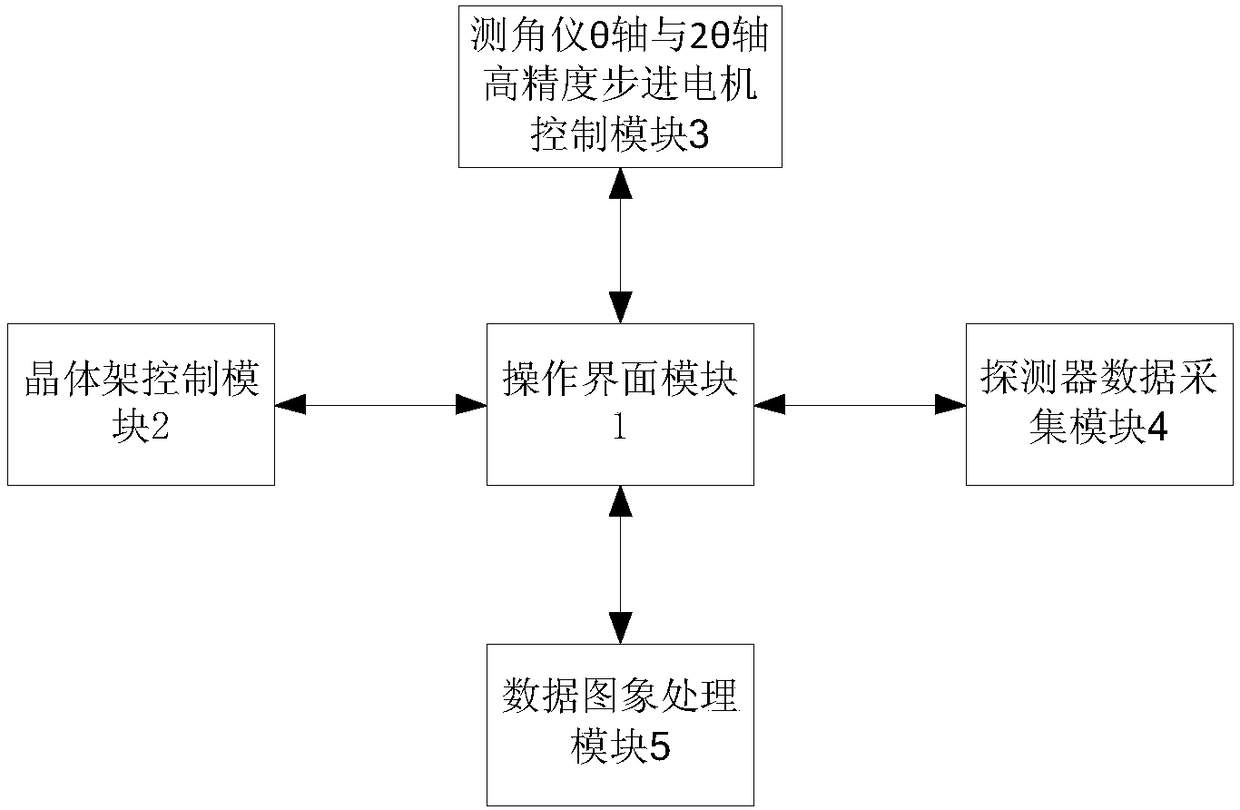

[0049] Such as figure 2 As shown, an X-ray fluorescence spectrometer automatic debugging and correction system for the spectroscopic optical path, the X-ray fluorescence spectrometer is a sequential wavelength dispersive X-ray fluorescence spectrometer, including a detector (6), a goniometer, a crystal frame and multiple spectroscopic The θ-axis and 2θ-axis of the goniometer are equipped with selected crystals and detectors respectively, and the system includes an operation interface module 1, a crystal frame control module 2, high-precision stepping motors for the θ-axis and 2θ-axis of the goniometer A control module 3 , a detector data collection module 4 and a data image processing module 5 .

[0050] The crystal frame control module 2 switches the selected crystal into the light splitting path.

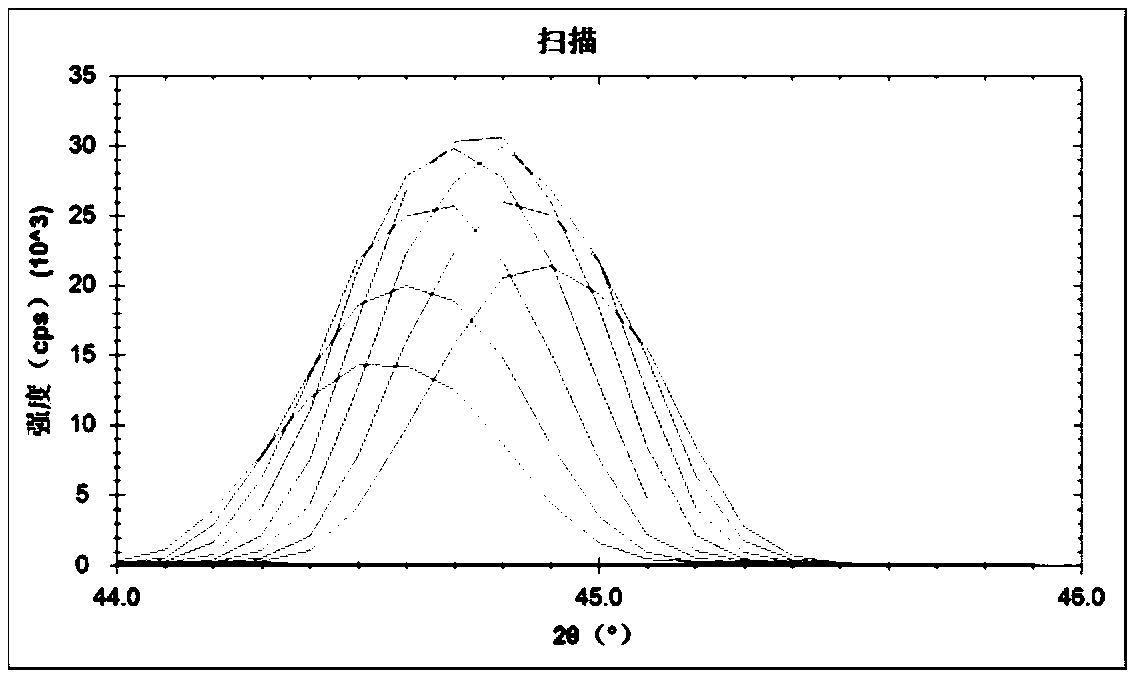

[0051] The user sets the scanning range of the goniometer θ axis and 2θ axis, the scan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com