Chemical production control system

A technology for control systems and chemical production, applied in general control systems, control/regulation systems, comprehensive factory control, etc., can solve problems such as system paralysis, slow response speed, and large memory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0088] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

[0089] The structure of the present invention will be described in detail below in conjunction with the accompanying drawings.

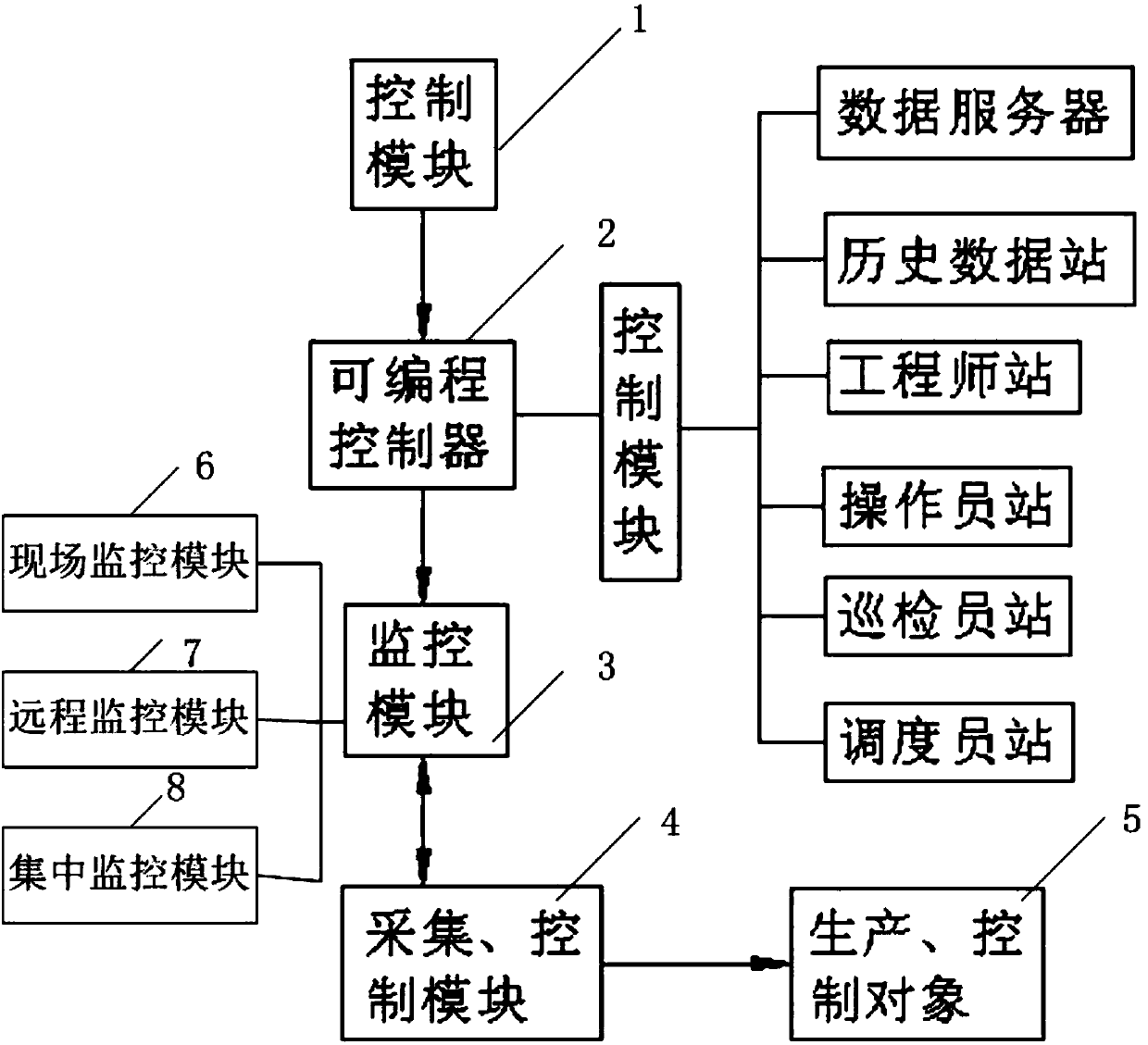

[0090] Such as figure 1 As shown, the chemical production control system provided by the embodiment of the present invention includes: a control module 1, a programmable controller 2, a monitoring module 3, an acquisition / control module 4 and a production / control object module 5, and the control module 1 is programmable through The controller 2 is connected with the monitoring module 3 .

[0091] The control module 1 includes a data server, a historical data station, an engineer station, an operator station, an inspector station and a dispatcher station, and the data server, an engineer station, an operator station, an inspector sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com