A negative electrode of metal lithium secondary battery and application thereof

A secondary battery, metal lithium technology, applied in the field of electrochemical energy storage, can solve the problems of easy detachment of lithium dendrites, no electrochemical activity, decrease in electrode capacity, etc. crystal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

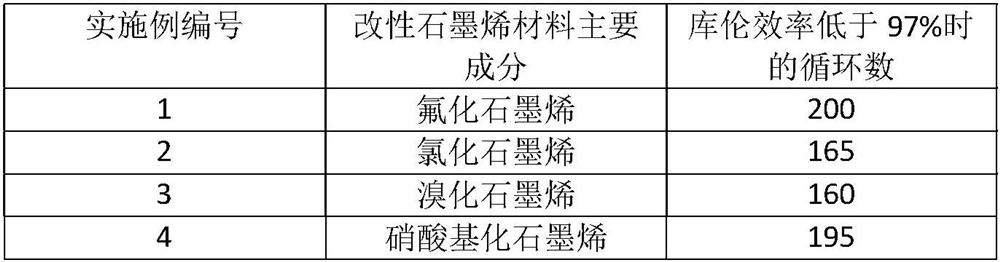

Embodiment 1

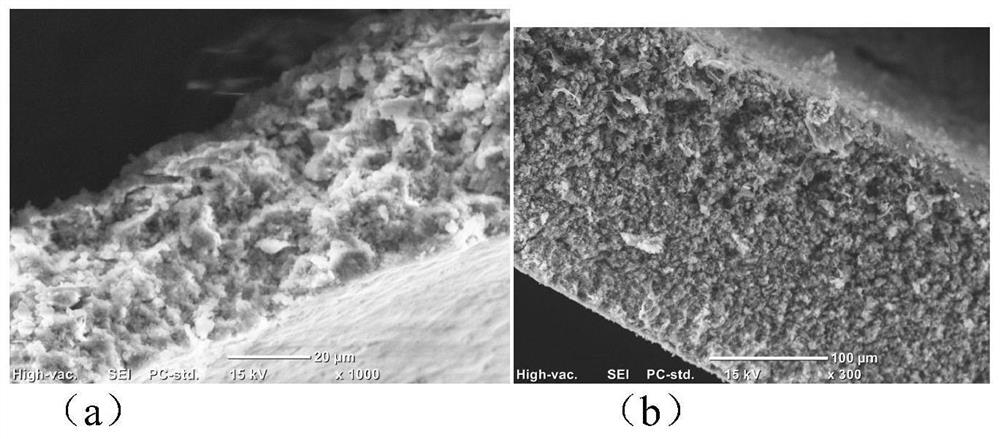

[0022] Preparation of modified graphene composite layer: take 0.5 g of fluorinated graphene and ultrasonically disperse it in 10 ml of ethanol. After suction filtration to form a film, dry at 100°C. The film thickness after drying was 0.1 mm. Then compound with metal lithium sheet.

[0023] figure 1 It can be seen that the battery containing the fluorinated graphene layer is much thinner than the ordinary battery without the fluorinated graphene layer, and the thickness of metal lithium is much thinner. It shows that the battery containing the fluorinated graphene composite layer has good cycle performance, because the irreversible deposition of metal lithium in the cycle process is reduced.

Embodiment 2

[0025] Preparation of modified graphene composite layer: take 0.5 g of chlorinated graphene and ultrasonically disperse it in 10 ml of ethanol. After suction filtration to form a film, dry at 100°C. The film thickness after drying was 0.1 mm. Then compound with metal lithium sheet.

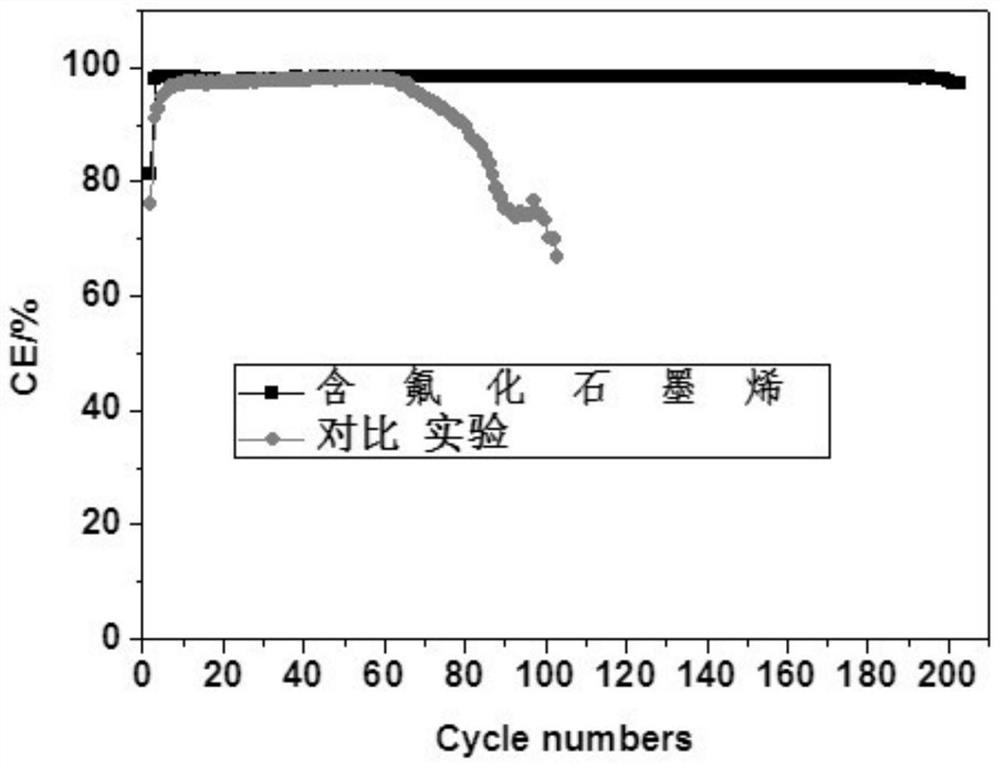

[0026] figure 2 It can be seen that the coulombic efficiency and stability of the battery with the composite fluorinated graphene coating are much better than the comparative test battery. The battery parameters are as follows: the positive pole is a lithium iron phosphate electrode. The active substance load is 15mgcm -2 , the negative electrode is lithium metal. Both the composite fluorinated graphene coating prepared in Example 2 and the diaphragm of the comparative test battery are polypropylene, and the difference is that there is no composite fluorinated graphene coating between the negative electrode and the diaphragm in the comparative test. The discharge rate is 10C, and the cut-of...

Embodiment 3

[0028] Preparation of modified graphene composite layer: 0.5 g of brominated graphene was ultrasonically dispersed in 10 ml of ethanol. After suction filtration to form a film, dry at 100°C. The film thickness after drying was 0.1 mm. Then compound with metal lithium sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com