Separator for electricity storage devices, and electricity storage device

A technology for power storage devices and separators, which is applied to lithium batteries, electrical components, battery pack components, etc., can solve problems such as battery capacity deterioration, and achieve the effects of improving safety, improving cycle characteristics, and suppressing dendrites.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

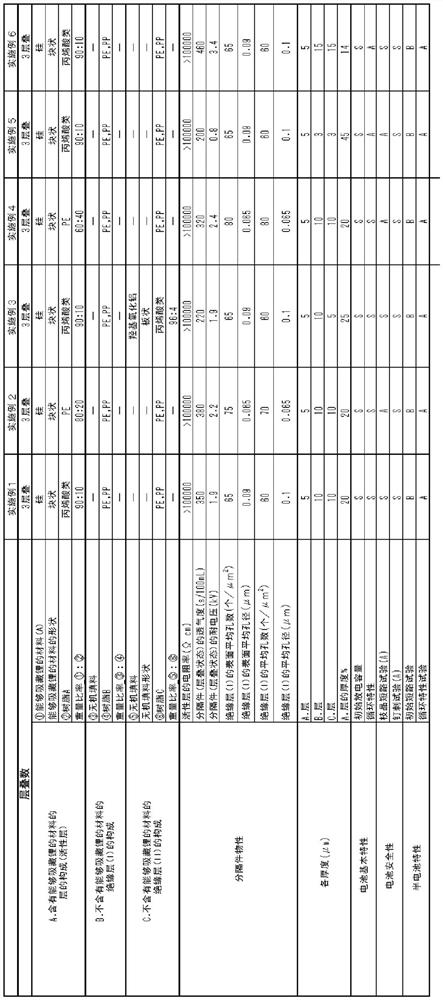

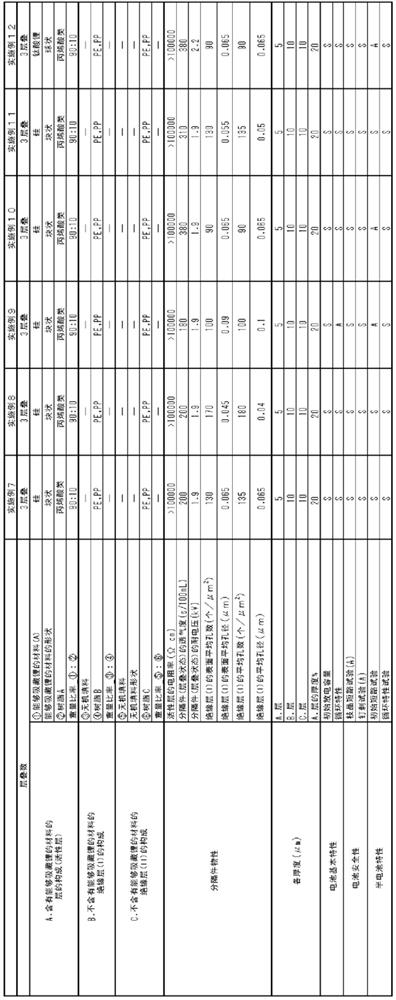

Embodiment 1

[0310] Mv is 45 mass parts of high-density polyethylene of the homopolymer of 700,000,

[0311] Mv is 45 parts by mass of high-density polyethylene of a homopolymer of 300,000, and

[0312] 5 parts by mass of a homopolymer polypropylene having an Mv of 400,000 was dry-blended with a drum mixer.

[0313] 1 mass part of tetrakis-[methylene-(3',5'-di-tert-butyl-4'-hydroxyphenyl)propionate]methane was added as an antioxidant to 99 mass parts of the obtained polyolefin mixture, Dry blending was again performed with a tumble mixer to obtain a mixture.

[0314] The obtained mixture was supplied to a twin-screw extruder with a feeder under a nitrogen atmosphere.

[0315] In addition, liquid paraffin (kinematic viscosity at 37.78°C is 7.59×10 -5 m 2 / s) Inject into the barrel of the extruder with a plunger pump.

[0316] The operating conditions of the feeder and the pump were adjusted so that the ratio of the liquid paraffin was 65 parts by mass and the polymer concentration was ...

Embodiment 2

[0322]As raw materials for insulating layers (I) and (II), 95 parts by mass of high-density polyethylene with Mv of 300,000, 5 parts by mass of polypropylene with Mv of 400,000, and tetrakis[methylene-3 -(3',5'-di-tert-butyl-4'-hydroxyphenyl) propionate] methane 1 mass part was mixed, and the 1st composition which comprises insulating layer (I) and insulating layer (II) was prepared.

[0323] As raw materials for the layer containing the material (A) capable of absorbing lithium, 80 parts by mass of silicon (average particle diameter 1 μm), 20 parts by mass of high-density polyethylene resin with Mv of 700,000, and 44.8 parts by mass of liquid paraffin as a plasticizer Parts by mass, and 1 part by mass of tetrakis[methylene-3-(3',5'-di-tert-butyl-4'-hydroxyphenyl) propionate] methane as an antioxidant is pre-mixed with a Henschel mixer , preparing a second composition constituting a layer (active layer) containing the material (A) capable of storing lithium.

[0324] The 1st ...

Embodiment 3

[0328] In Example 1, 96.0 parts by mass of plate-shaped aluminum oxyhydroxide (average particle diameter: 1.0 μm) and acrylic polymer latex (solid content concentration: 40%, Average particle diameter 145nm, Tg-10°C) 4.0 parts by mass, and ammonium polycarboxylate aqueous solution (SN Dispersant 5468 manufactured by San Nopco Co., Ltd. SN Dispersant 5468) 1.0 parts by mass were uniformly dispersed in 100 parts by mass of water to prepare a coating liquid, using gravure coating Loom coating is applied to a layer (active layer) containing a material capable of storing lithium. The coating layer on the active layer was dried at 60° C. to remove water to obtain a multilayer porous film in which an insulating layer (II) having a thickness of 5 μm was formed on the active layer. In addition, the battery was produced so that the insulating layer (II) might face the negative electrode surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Air permeability | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Surface average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com