Combustible gas wet type purification equipment in new energy field

A technology of purification equipment and new energy, applied in the direction of fuel, gas fuel, chemical instruments and methods, etc., can solve the problems of single purification method, low purity of combustible gas, inconvenient use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

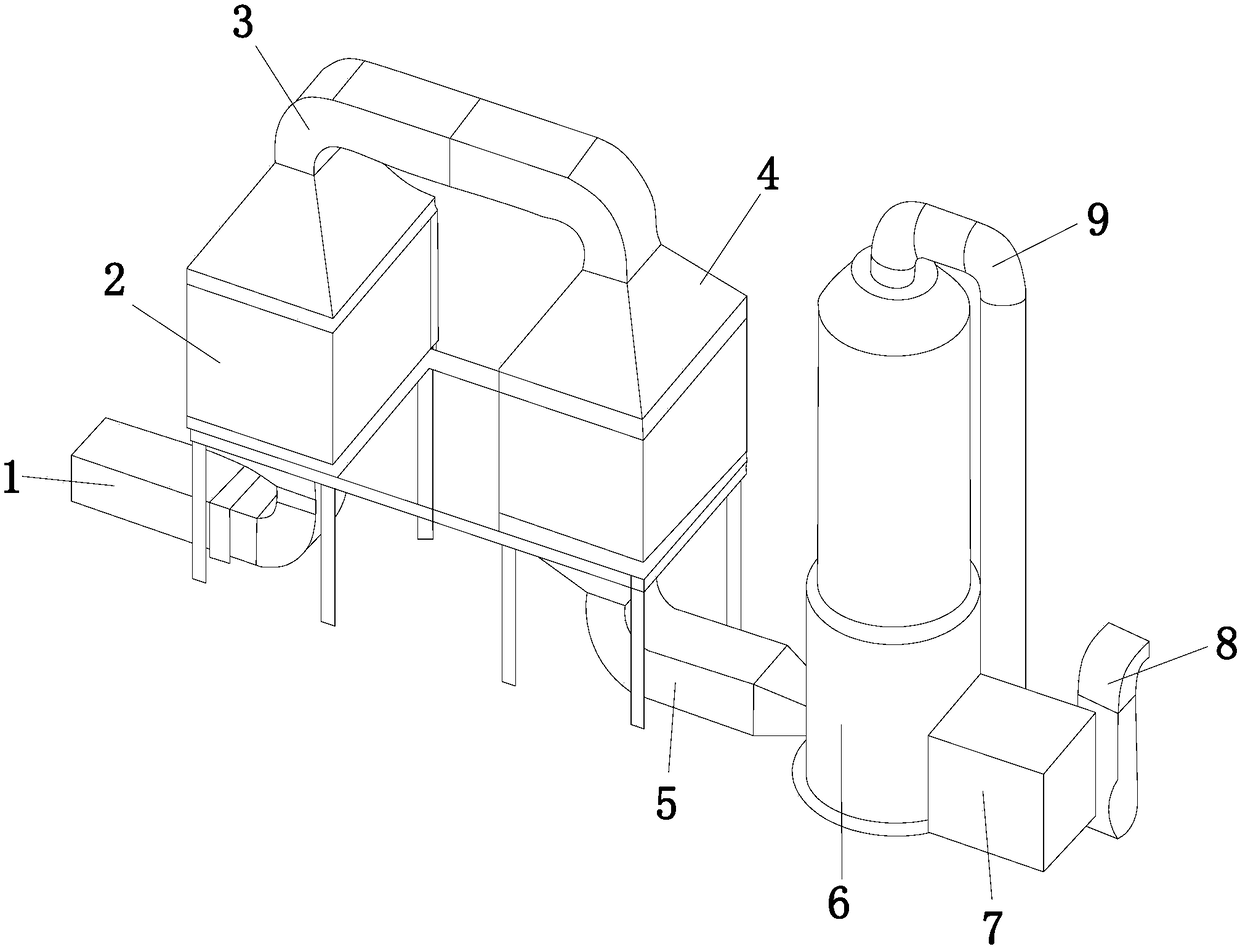

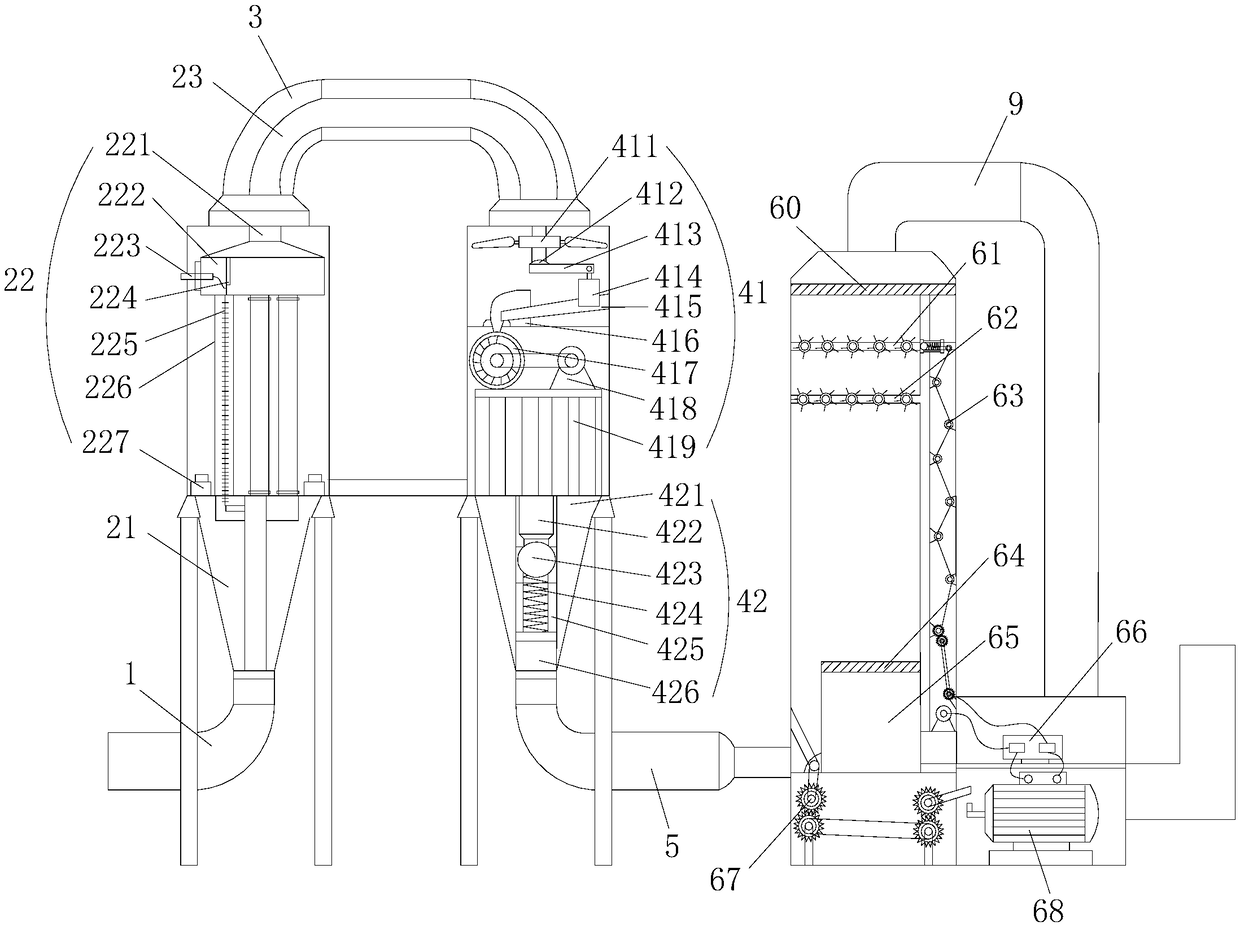

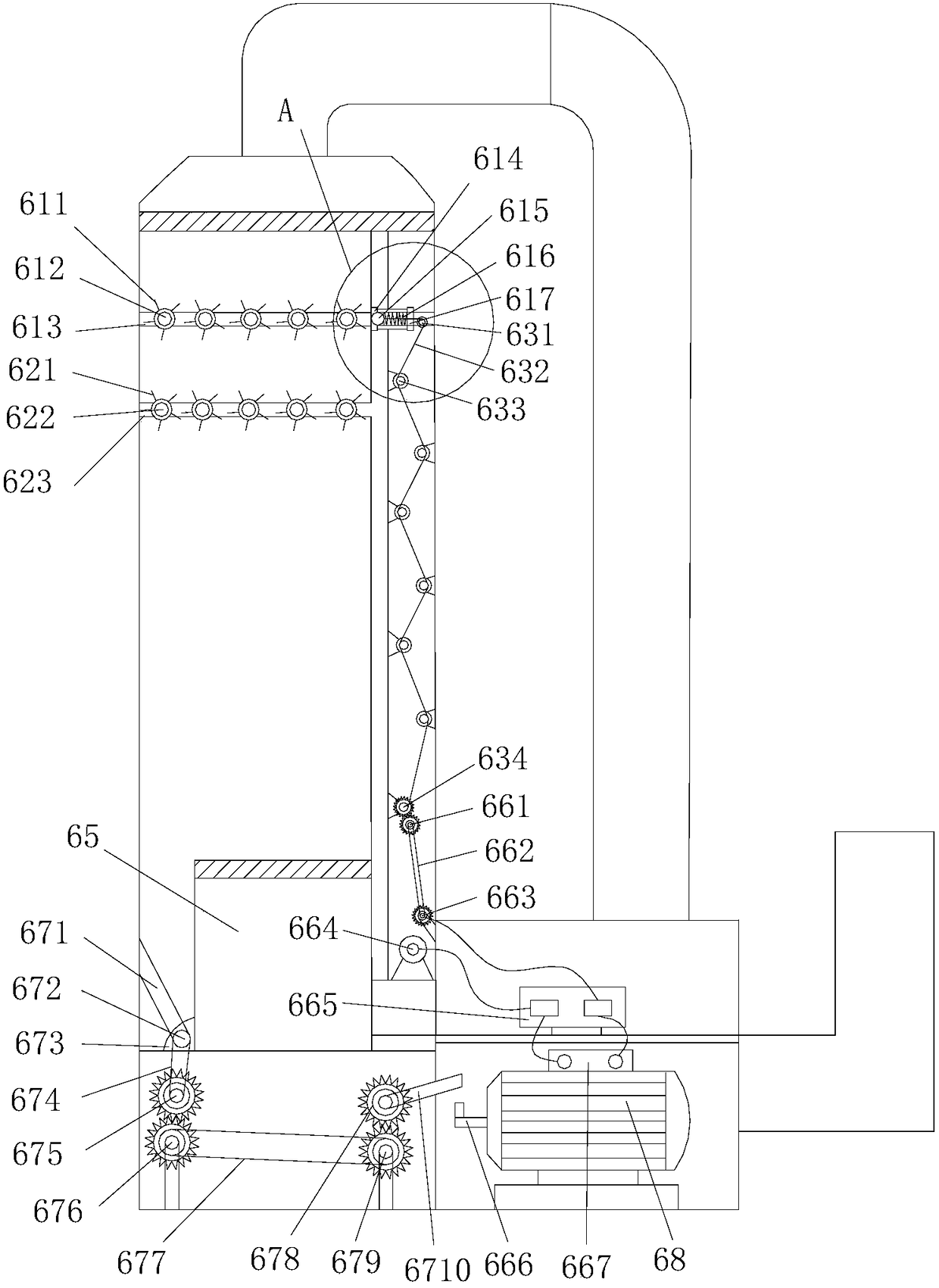

[0029] see Figure 1-Figure 5 , the present invention provides a combustible gas wet purification equipment in the field of new energy, the structure of which includes an intake pipe 1, a dust removal box 2, a connecting pipe 3, a tar cracking reactor 4, a first-stage gas outlet pipe 5, a purification tower 6, and a control box 7. Air outlet 8, secondary air outlet pipe 9, the bottom port of the dust removal box 2 is welded to the intake pipe 1 and communicates with each other, and the upper port of the dust removal box 2 is connected to the tar cracking reactor 4 through a fixed connection pipe 3 In communication, the bottom port of the tar cracking reactor 4 is welded with a primary gas outlet pipeline 5 and is connected with the purification tower 6, and one end of the secondary gas outlet pipeline 9 is installed on the upper end of the purification tower 6, and the other end is integrated with the gas outlet 8 The control box 7 is a square structure and is fixedly installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com