Air-suction-type specific gravity stone removing equipment and process for dehydrated garlic

A technology of garlic and air suction, applied in the direction of solid separation, separating solids from solids with air flow, chemical instruments and methods, etc., can solve problems such as damaged silica gel plates, achieve burden reduction, avoid pollution of the environment, and applicability wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

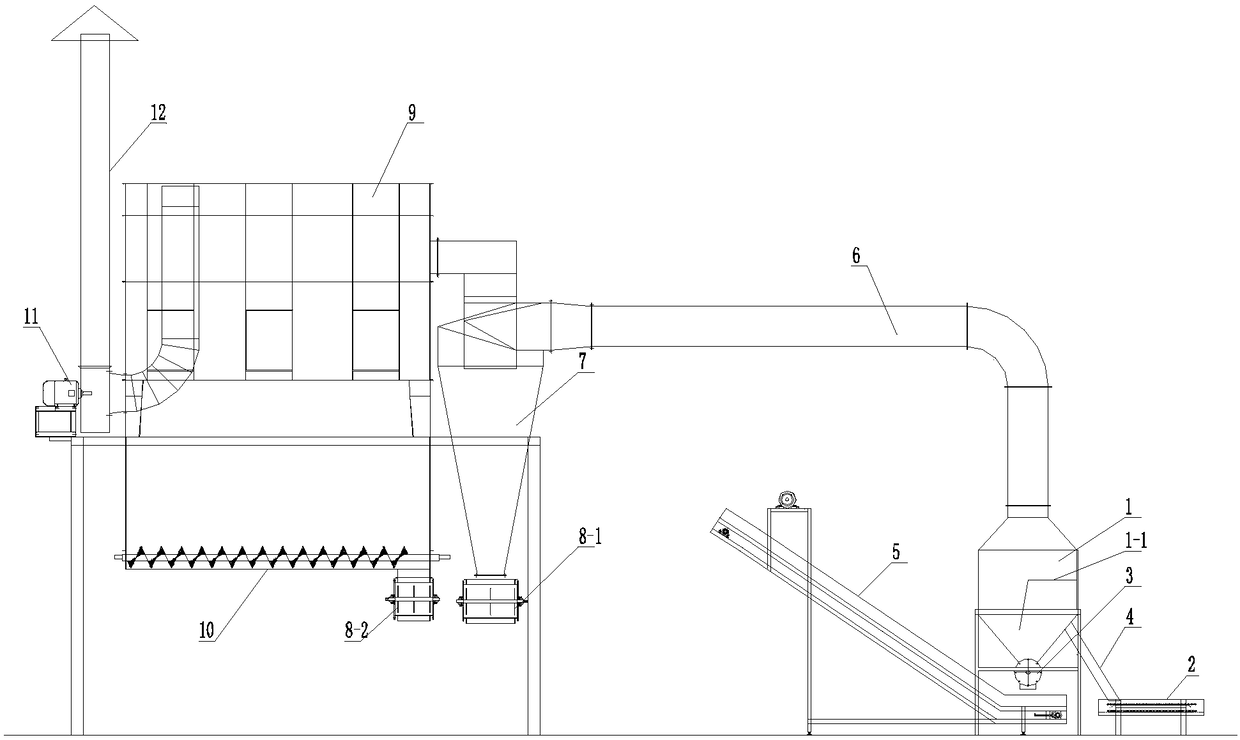

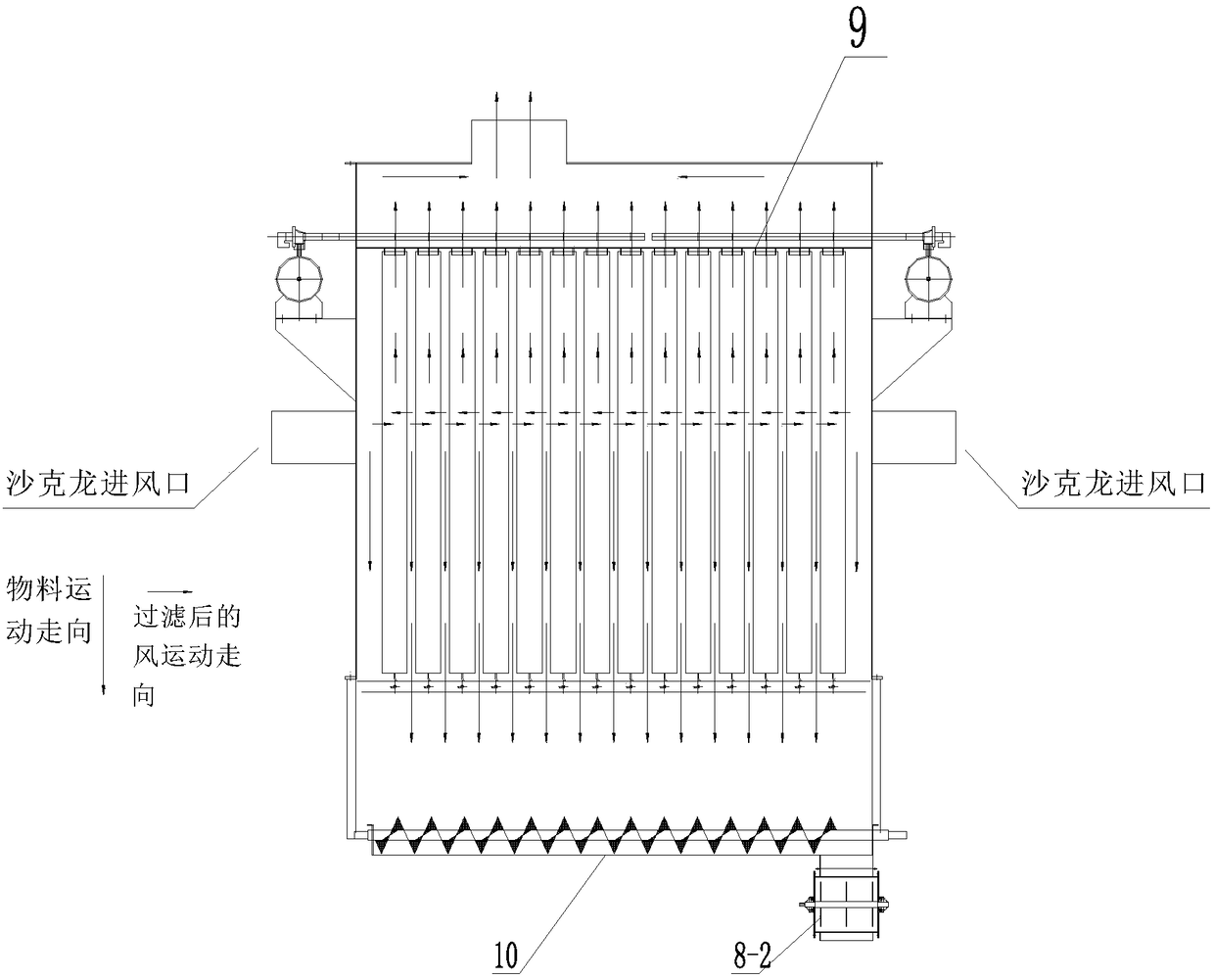

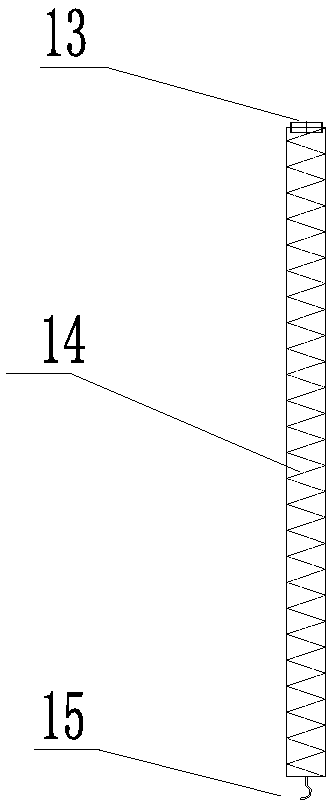

[0028] Such as figure 1 As shown, a dehydration garlic air suction specific gravity stone removal equipment includes a feed conveyor belt 2, a suction material channel 4, a buffer box 1, a discharge conveyor belt 5, an air suction pipeline 6, a sacron 7, and an air locker a8-1, air locker b8-2, pulse dust collector 9, conveying auger 10, fan 11, exhaust duct 12, both sides of the buffer box 1 are respectively provided with a feed conveyor belt 2 and a discharge conveyor Belt 5, the end of the feed conveyor belt 2 is connected to the buffer box 1 through the suction material channel 4, one end of the discharge conveyor belt 5 extends horizontally to the bottom of the buffer box 1, and the other end of the discharge conveyor belt 5 extends obliquely upwards to The outside of the buffer box 1; the interior of the buffer box 1 is provided with an inner baffle plate 1-1, and a discharge locker 3 is arranged directly below the inner baffle plate 1-1; the top of the buffer box 1 is s...

Embodiment 2

[0040] On the basis of embodiment 1, a kind of dehydration garlic air suction specific gravity destonening process specifically comprises the following steps:

[0041] (1) Stone-removing cache: transport the garlic to be stone-removed to the suction material channel 4 through the feeding conveyor belt 2, and the garlic and volatile components are absorbed into the buffer box under the action of the fan 11 and the high-speed airflow generated In 1, stones heavier than garlic fall to the ground with the operation of feeding conveyor belt 2, and are separated from the material;

[0042] (2) Impurity removal: The impurities on the surface of the garlic entering the buffer box 1 enter the pulse dust collector 9 through the Shacron 7, and pass through the filter bag of the pulse dust collector 9 with the airflow to filter, and the filtered gas flows along the exhaust Air duct 12 discharges;

[0043] (3) Miscellaneous materials collection: Miscellaneous materials processed by Shacro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com