Orthogonal cutting online dynamic microscopic testing method and device based on vertical type computer numerical control milling machine

A CNC milling machine and cutting test technology, which is applied in the direction of metal processing machinery parts, measuring/indicating equipment, metal processing equipment, etc., can solve the problems of small optical magnification, inconvenient installation, and inability to observe by turning, and achieve the realization of feed speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

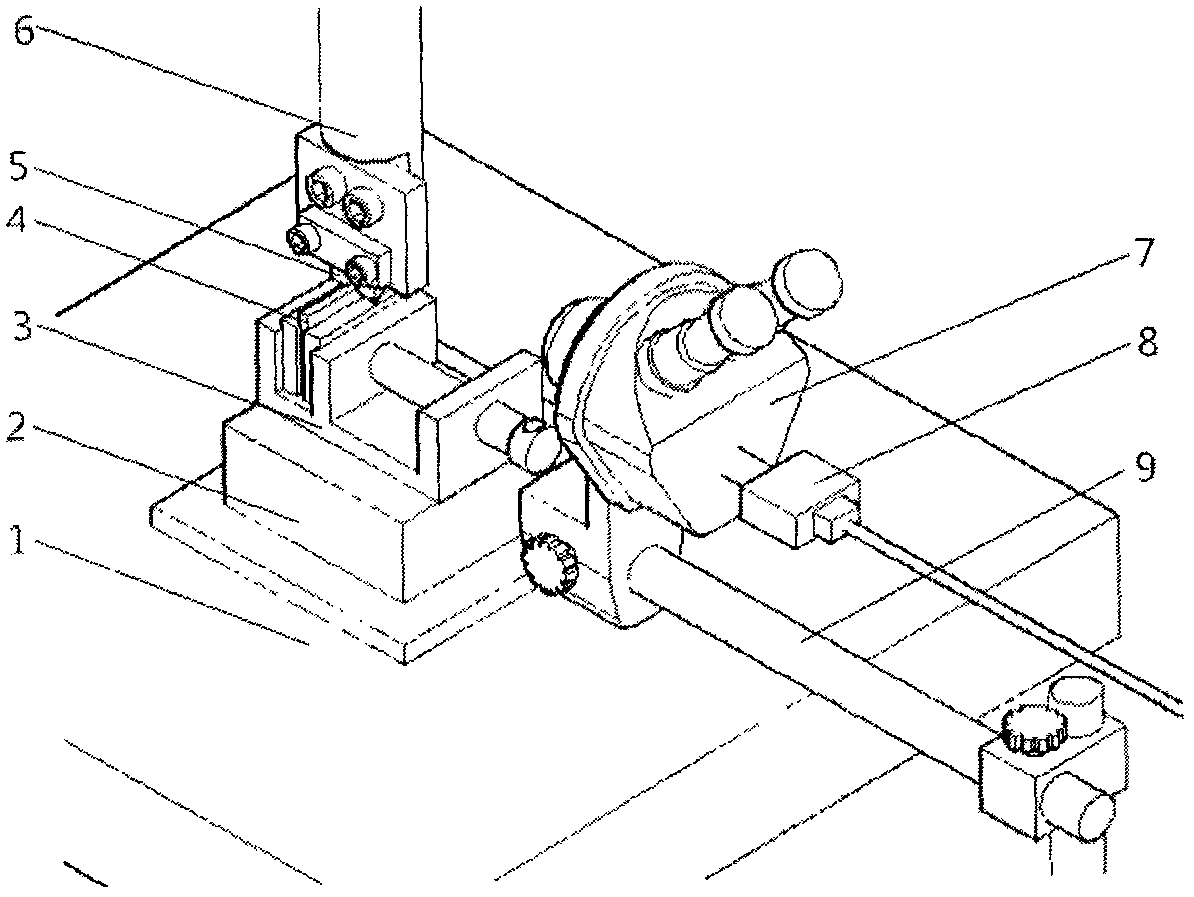

[0034] (1) Refer to figure 1 , set up an online dynamic microscopic test platform for orthogonal cutting on a vertical CNC milling machine, and prepare for orthogonal cutting experiments.

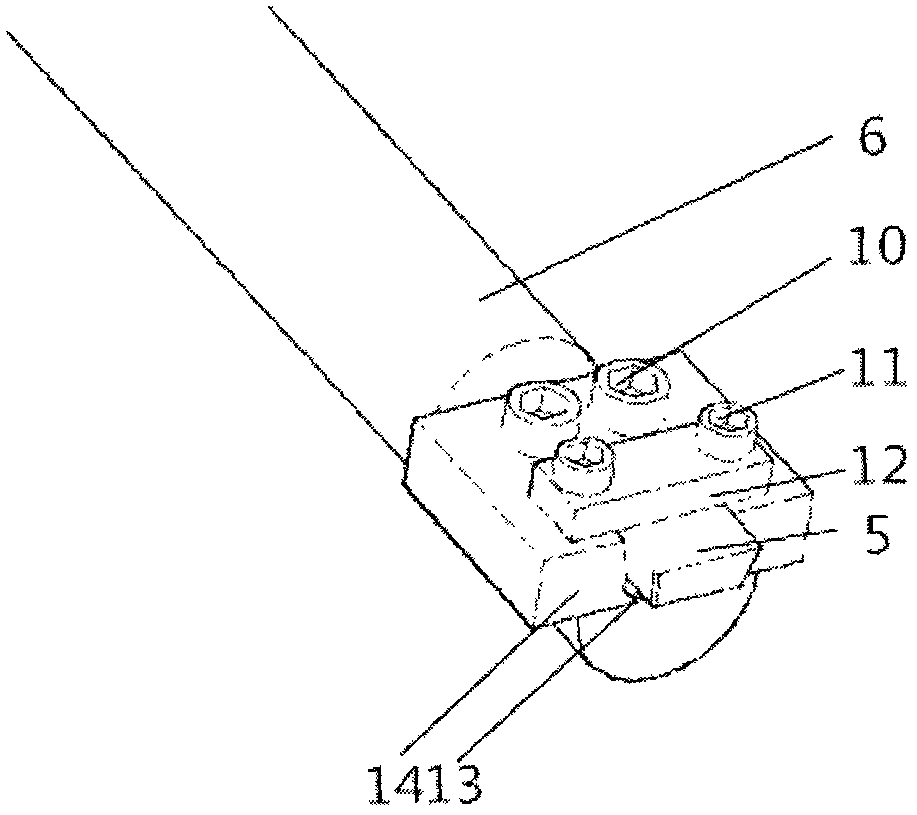

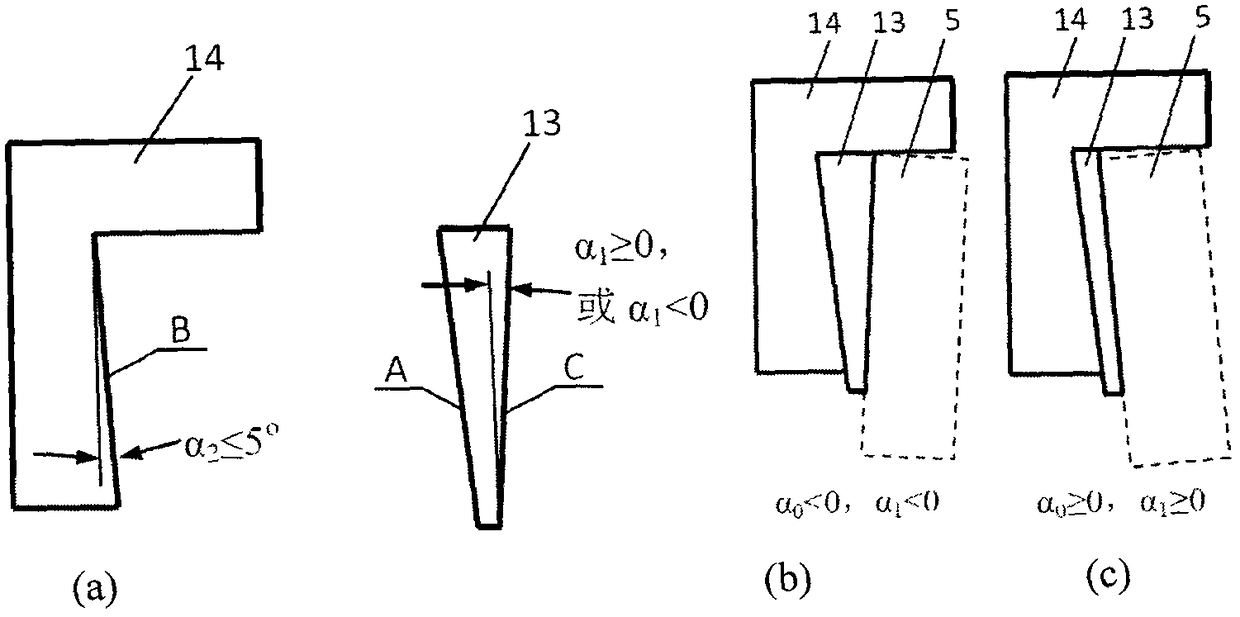

[0035] (1) Refer to figure 2 and image 3 , choose the inclination angle α 1 = 5° Angle adjustment gasket 13 is placed under the bottom of the blade 5, and the blade 5 is loaded into the knife holder 14 through the pressure plate screw 11 and the pressure plate 12; , to complete the installation of the self-made tool holder.

[0036] (3) Refer to figure 1 , the test workpiece is prefabricated into a sheet part 4 with a thin upper part and a thicker lower part. The upper part has a thickness of 0.5mm and a height of 20mm, and the lower part has a thickness of 5mm and a height of 30mm. .

[0037] (4) Refer to figure 1 , refit the stereo microscope 7 and the CCD image acquisition system 8 in the horizontal direction through the universal bracket 9, and install and adjust the orthogonal c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com