Drive-by-wire hydraulic brake system and brake control method for independently controlling four-wheel pressure

An independent control and hydraulic braking technology, which is applied in the direction of braking transmission device, braking action starting device, brake, etc., can solve the problems of high price, high performance requirements of motor, and large volume of vacuum booster, so as to improve comfort , Simplify the system structure and ensure the effect of driving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] In order to further illustrate the technical solutions of the present invention and the beneficial effects brought by them, in conjunction with the accompanying drawings, the specific details of the present invention

[0066] The implementation is as follows:

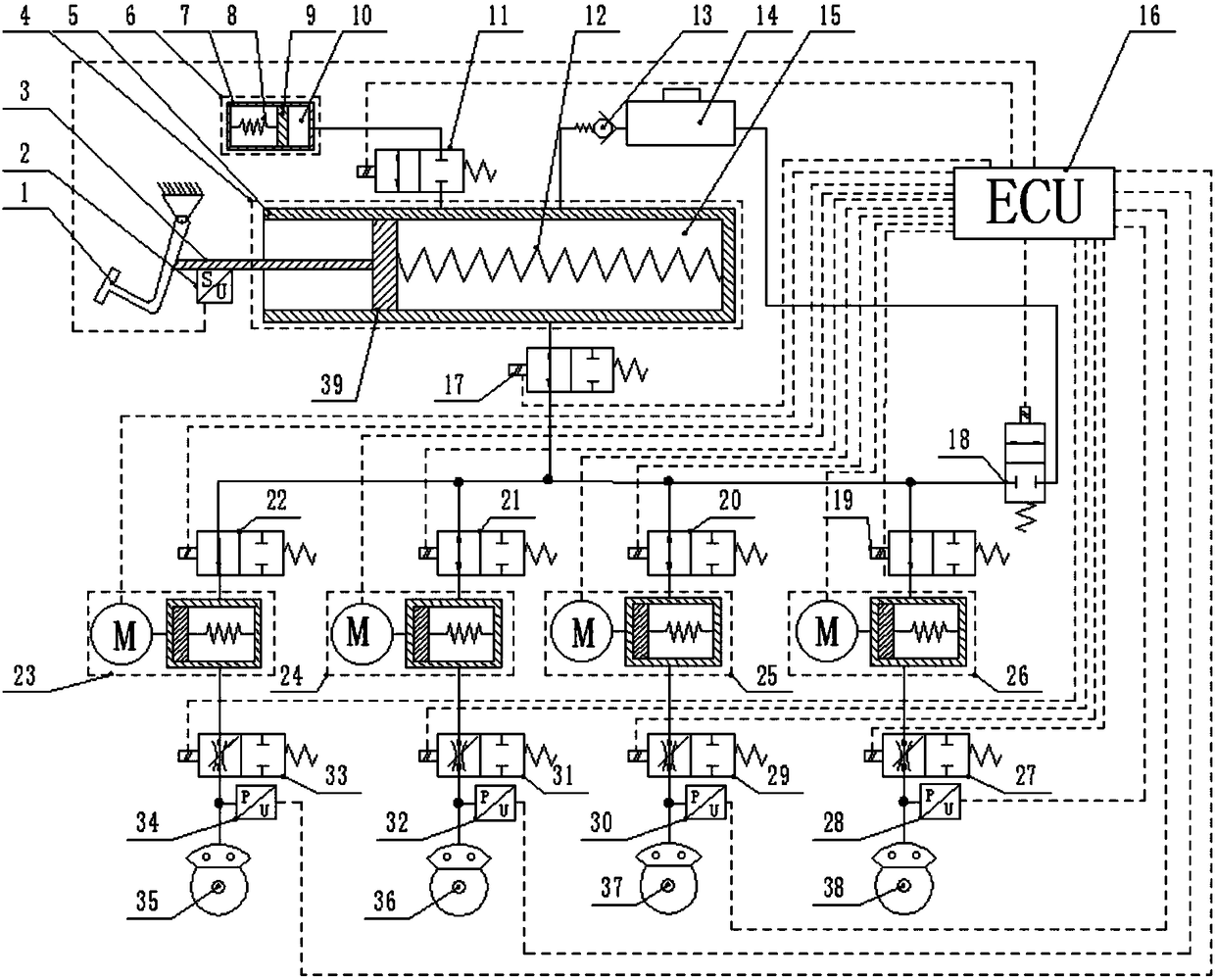

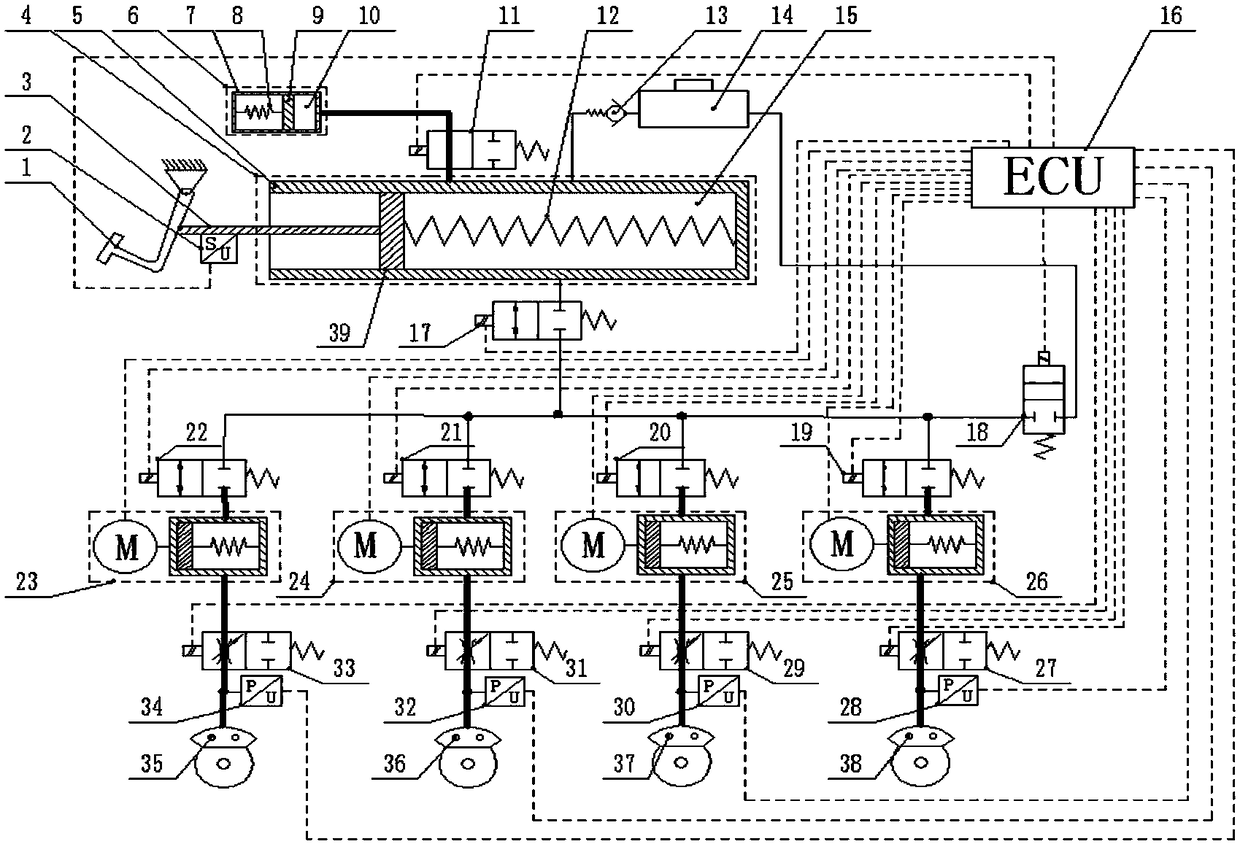

[0067] The invention provides a wire-controlled hydraulic braking system independently controlled by four wheel pressures. The braking system consists of a brake pedal mechanism,

[0068] Composed of electronic control unit ECU, pressure control unit and brake wheel cylinder.

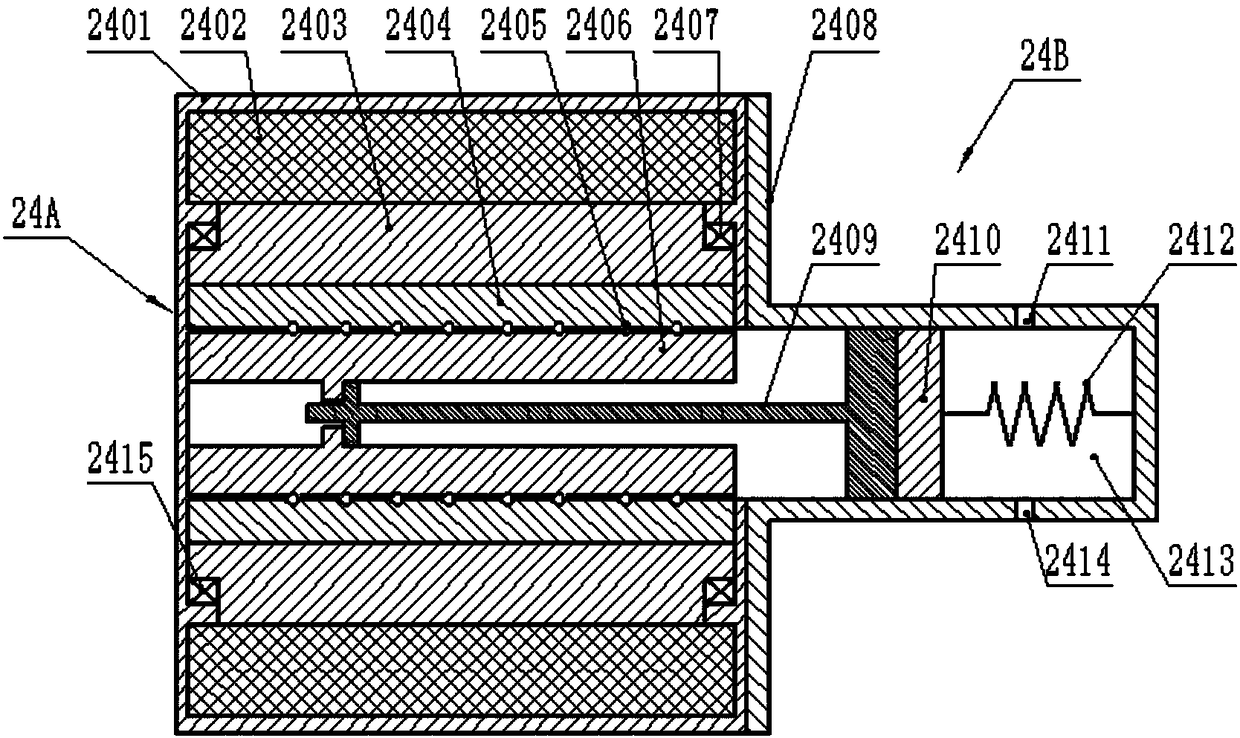

[0069] Such as figure 1 As shown, the brake pedal mechanism is composed of a brake pedal 1, a brake master cylinder 4, a pedal feeling simulator 6 and an oil storage cup 14; the brake master cylinder 4 is composed of a pedal push rod 3, a pedal displacement sensor 2 , brake master cylinder piston 39, brake master cylinder piston return spring 12, and brake master cylinder housing 5; Composed of a simulator piston 9 and a simulator sprin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com