Combination method for improving sludge dewatering effect of membrane filter press

A membrane filter press and sludge dewatering technology, which is applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve the problems of difficult removal and high cost, and achieve fast separation speed and low Moisture content, the effect of improving the dehydration effect decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The invention provides a combined method for improving the sludge dewatering effect of a membrane filter press, comprising:

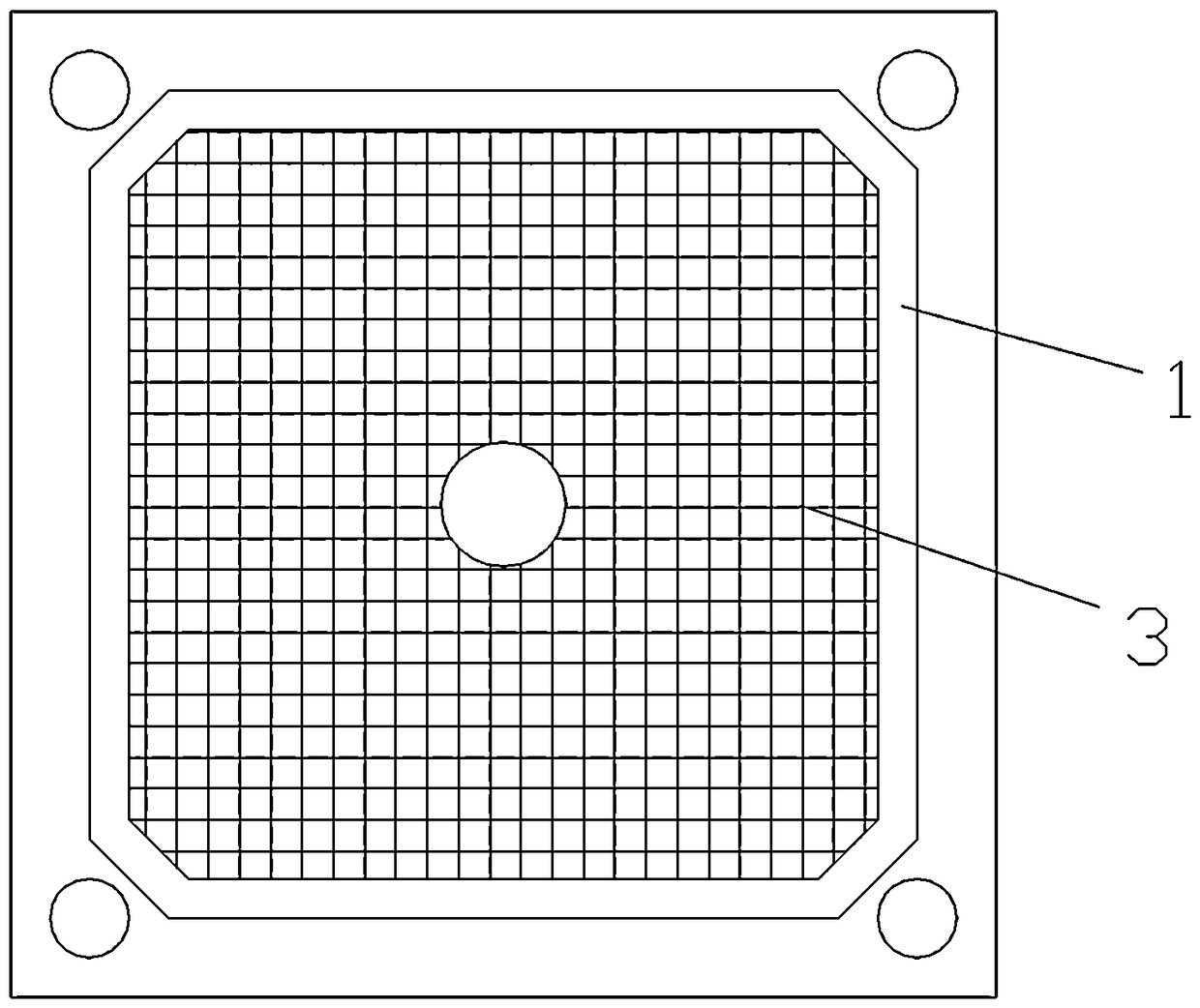

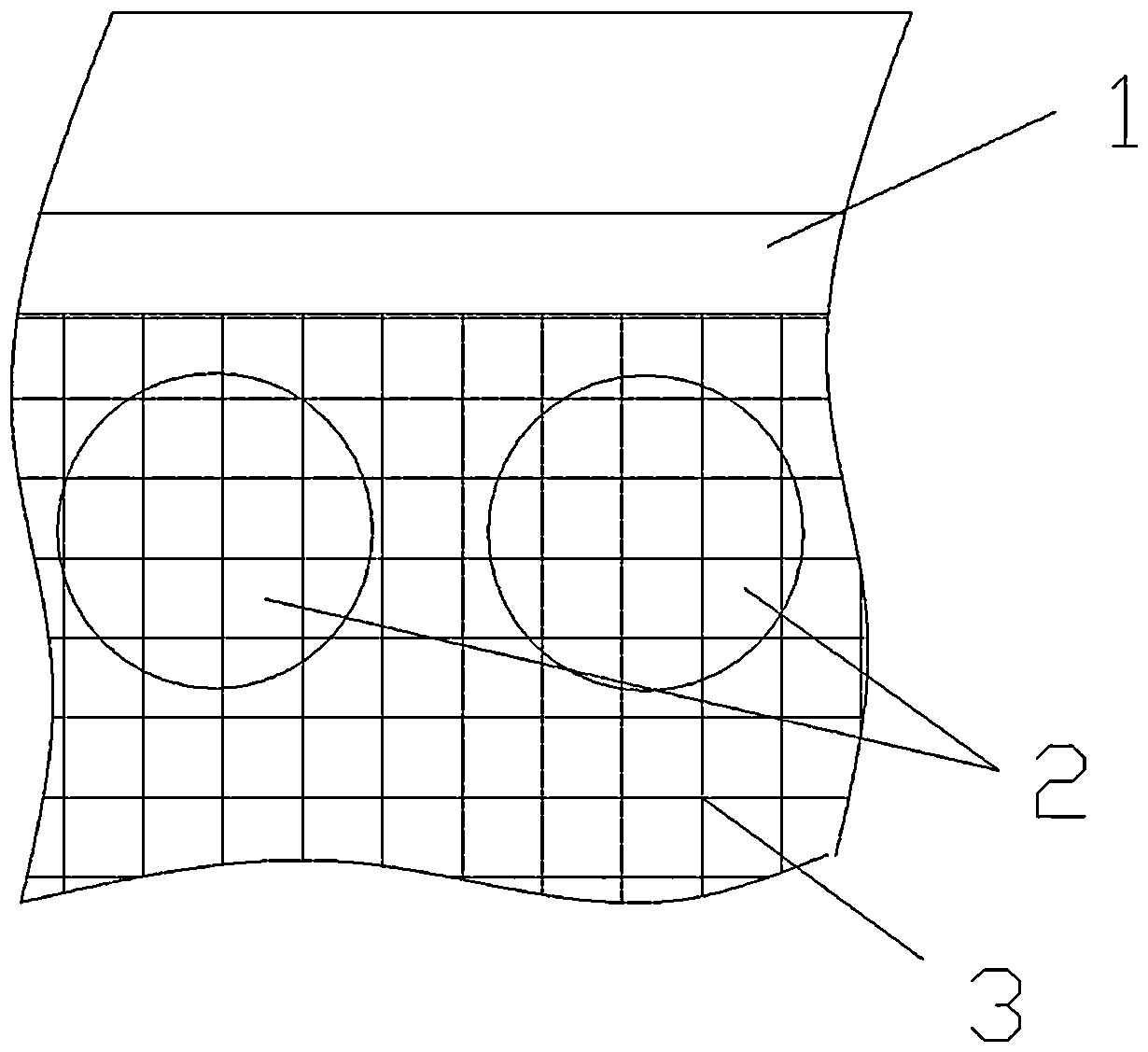

[0025] a. to combine Figure 1~3 As shown, a grid pad 3 is laid on the outer side of each filter plate 1 of the diaphragm filter press, and the grid aperture of the grid pad 3 is smaller than the distance between two adjacent flow guide protrusions 2 on the outer side of the filter plate 1; as a preferred Yes, the grid aperture of the grid pad 3 is 1-2 mm, the thickness of the grid pad 3 is 1-2 mm, and the grid pad 3 is preferably made of corrosion-resistant and deformation-resistant materials, such as polypropylene;

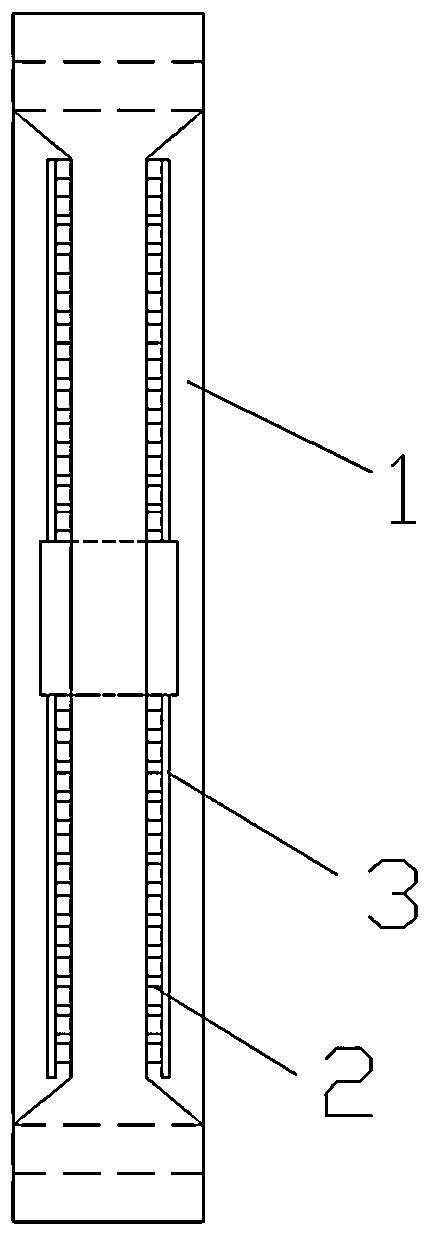

[0026] b. Combine Figure 4 As shown, after the pressing of the diaphragm filter press, the blower is used to ventilate and purge the filter cake in the filter press; when ventilating and purging, a diagonally staggered purge method is used to make the vents and drains on different sides work in pairs. .

[0027] In this example...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com