Preparation method of concrete coagulant

A coagulation accelerator and concrete technology, applied in the field of cement admixtures, can solve problems such as poor setting speed and strength, and achieve the effects of improving the coagulation acceleration effect, reducing the final setting time, and accelerating the hydration process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

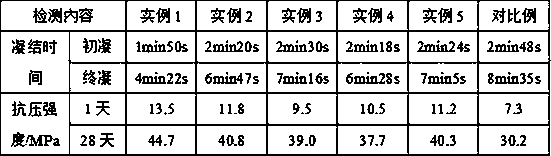

Examples

example 1

[0021] Mix sepiolite and water in a beaker at a mass ratio of 1:5, and add nano-silica of 0.3 times the mass of sepiolite to the beaker, move the beaker into an ultrasonic oscillator, and vibrate ultrasonically at a frequency of 65kHz After 30 minutes, filter to obtain pretreated sepiolite; mix the pretreated sepiolite and saturated calcium chloride solution in a flask at a mass ratio of 1:6, lower the temperature in the flask to 25°C, and then add Pretreat dopamine with 0.5 times the mass of sepiolite, adjust the pH of the system in the flask to 8.8 with a sodium hydroxide solution with a mass fraction of 8%, soak for 70 minutes at a temperature of 25°C, and filter to obtain a filter cake. The cake was moved into a drying oven, and dried at a constant temperature for 30 minutes at a temperature of 50°C to obtain modified sepiolite; polyacrylamide and polyallylamine were mixed at a mass ratio of 3:1, and mixed with polyacrylamide and polyolefin Add absolute ethanol 0.3 times t...

example 2

[0023]Mix polyacrylamide and polyallylamine at a mass ratio of 3:1, and add absolute ethanol 0.3 times the mass of polyacrylamide to the mixture of polyacrylamide and polyallylamine, at a temperature of 15°C and a speed of 450r / After stirring and mixing for 12 minutes under the condition of 1 min, the mixed solution was obtained; the paraffin and waste paper pulp were mixed in the reactor at a mass ratio of 4:1, and sodium bicarbonate with 0.4 times the mass of paraffin and sodium bicarbonate with 0.2 times the mass of paraffin were added to the reactor. Dispersant, after stirring and mixing for 30 minutes at a temperature of 55°C and a rotational speed of 320r / min, freeze and pulverize the materials in the reaction kettle, and pass through a 180-mesh sieve to obtain additives; weigh 6 parts in sequence according to parts by weight Sodium metaaluminate, 5 parts of calcium oxide, 20 parts of mixed solution, 12 parts of additives, 0.8 times of emulsifier and 0.3 times of dispers...

example 3

[0025] Mix sepiolite and water in a beaker at a mass ratio of 1:5, and add nano-silica of 0.3 times the mass of sepiolite to the beaker, move the beaker into an ultrasonic oscillator, and vibrate ultrasonically at a frequency of 65kHz After 30 minutes, filter to obtain pretreated sepiolite; mix the pretreated sepiolite and saturated calcium chloride solution in a flask at a mass ratio of 1:6, lower the temperature in the flask to 25°C, and then add Pretreat dopamine with 0.5 times the mass of sepiolite, adjust the pH of the system in the flask to 8.8 with a sodium hydroxide solution with a mass fraction of 8%, soak for 70 minutes at a temperature of 25°C, and filter to obtain a filter cake. Move the cake into a drying oven, and dry at a constant temperature for 30 minutes at a temperature of 50°C to obtain modified sepiolite; add anhydrous ethanol with 0.1 times the mass of polyallylamine to the polyallylamine, at a temperature of 15°C, rotate After stirring and mixing for 12 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com