Method for electrolyzing aluminum at low temperature in deep eutectic solvent

A deep eutectic solvent and electrolytic metal technology, applied in the field of materials, can solve the problems of high price, secondary pollution, high viscosity, etc., and achieve the effects of low preparation cost, avoiding the generation of dendritic aluminum, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

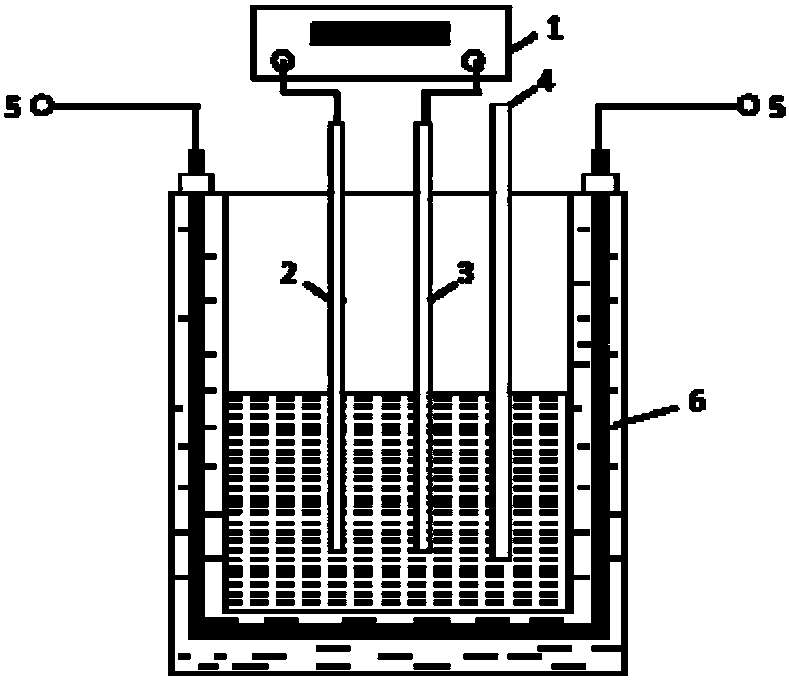

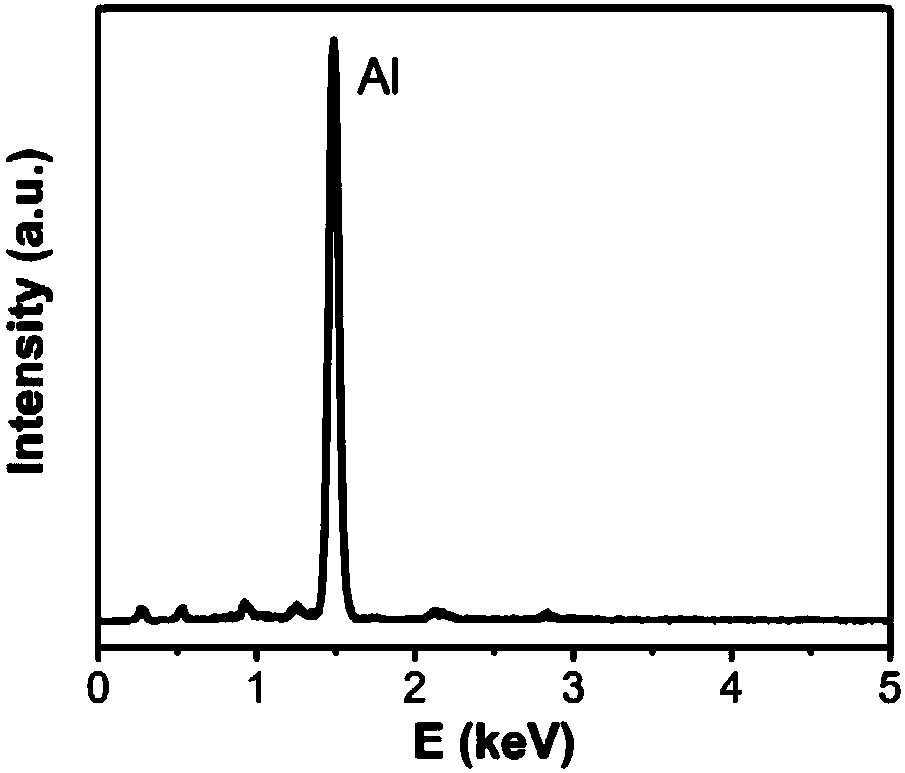

[0039] Preparation of oxalic acid-polyethylene glycol deep eutectic solvent, the mol ratio of oxalic acid and polyethylene glycol with a number average molecular weight of 200 is 1:2, 1:4, 1:6, 1:8, wherein the amount of fixed oxalic acid is 0.1mol. , heated and stirred at 40°C for 10 min to form an oxalic acid-polyethylene glycol deep eutectic solvent. Weigh 0.1g of alumina and dissolve in oxalic acid-polyethylene glycol deep eutectic solvent, heat and stir, use this system as electrolyte, use soluble aluminum matrix composite material as anode, stainless steel sheet as cathode, and fix the distance between electrodes at 1.5cm , for electrolysis. During the electrolysis process, the temperature is 25°C and the current density is 60-100mA·cm -2 And the working voltage is 1.8-2V. After electrolysis for 0.5h, the copper sheet was soaked in absolute ethanol, and after drying, the aluminum layer was peeled off, weighed, and the efficiency was calculated.

[0040] The results o...

Embodiment 2

[0044] Prepare a choline chloride-polyethylene glycol deep eutectic solvent, the molar ratio of oxalic acid to polyethylene glycol with a number average molecular weight of 200 is 1:2, 1:4 and 1:6, heat and stir at 30°C for 10 minutes to form Choline chloride-polyethylene glycol deep eutectic solvent, in which the amount of choline chloride fixed is 0.1mol. Weigh 0.1g of alumina and dissolve it in the choline chloride-polyethylene glycol deep eutectic solvent, heat and stir, use this system as the electrolyte, use the soluble aluminum matrix composite material as the anode, and the stainless steel sheet as the cathode, and fix the distance between the electrodes 1.5cm, electrolysis. During the electrolysis process, the temperature is 25°C and the current density is 160-200mA·cm -2 And the working voltage is 1.8-2V. After 4 hours of electrolysis, the copper sheet was soaked in absolute ethanol, and after drying, the aluminum layer was peeled off, weighed, and the efficiency w...

Embodiment 3

[0049] Prepare urea-polyethylene glycol deep eutectic solvent, the molar ratio of oxalic acid to polyethylene glycol is 1:2, 1:4 and 1:6, heat and stir at 35°C for 10min to form urea-polyethylene glycol deep eutectic Solvent, wherein the amount of fixed urea is 0.1mol. Weigh 0.1g of alumina and dissolve it in urea-polyethylene glycol deep eutectic solvent, heat and stir, use this system as electrolyte, use soluble aluminum matrix composite material as anode, stainless steel sheet as cathode, and fix the distance between electrodes at 1.5cm , for electrolysis. During the electrolysis process, the temperature is 25°C and the current density is 80-100mA·cm -2 And the working voltage is 1.8-2V. After 8 hours of electrolysis, the copper sheet was soaked in absolute ethanol, and after drying, the aluminum layer was peeled off, weighed, and the efficiency was calculated.

[0050] The results obtained are: the molar ratios of the prepared urea-polyethylene glycol deep eutectic solv...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap