A hydraulic system automatic exhaust device and method for an electro-hydraulic brake test bench

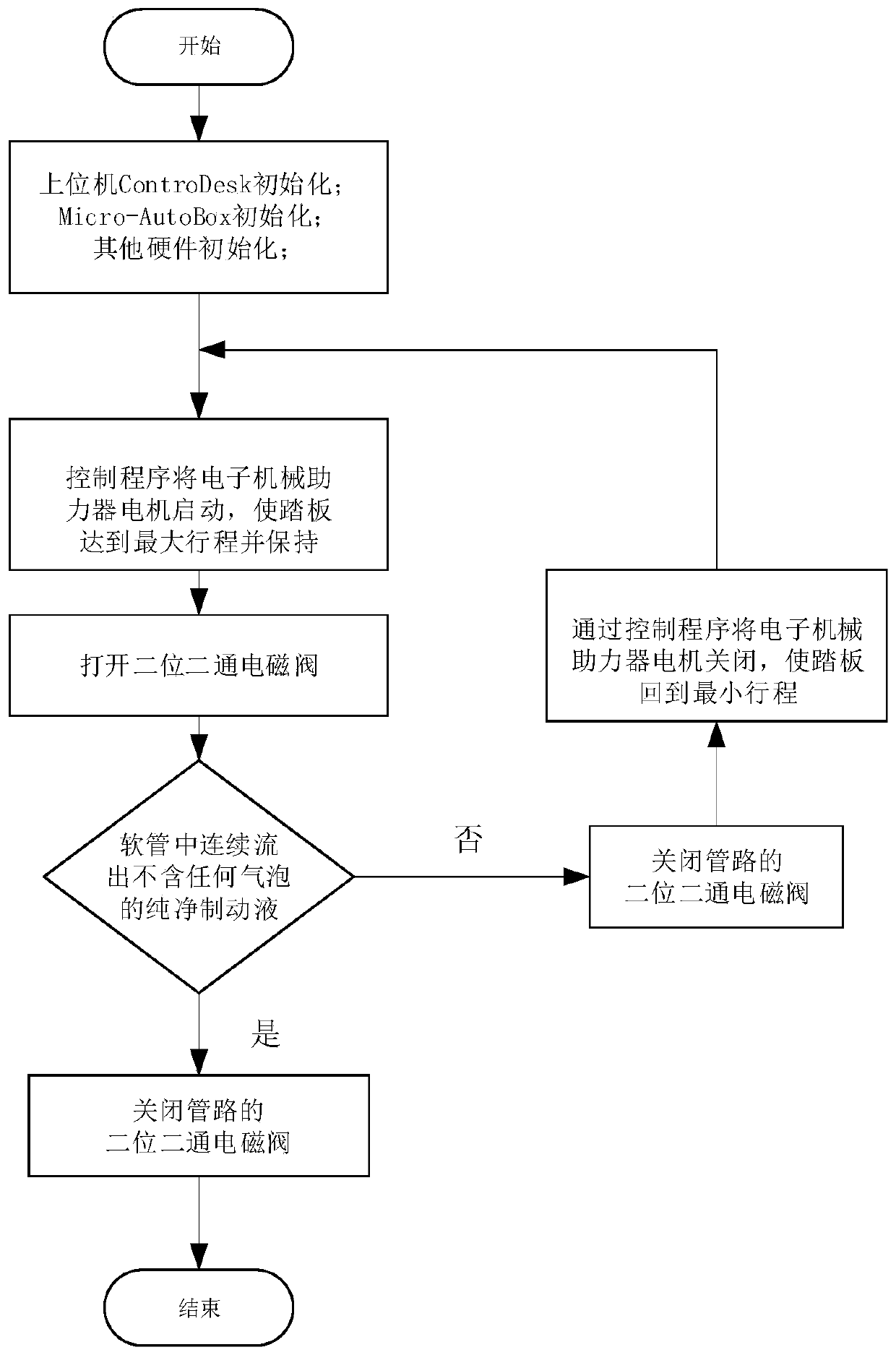

A test bench and automatic exhaust technology, applied in fluid pressure actuation devices, fluid pressure actuation system components, fluid pressure actuation system testing, etc., can solve brake fluid corrosion, incomplete exhaust, and time-consuming air To achieve the effect of clean exhaust, avoid dirty exhaust, and precise travel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

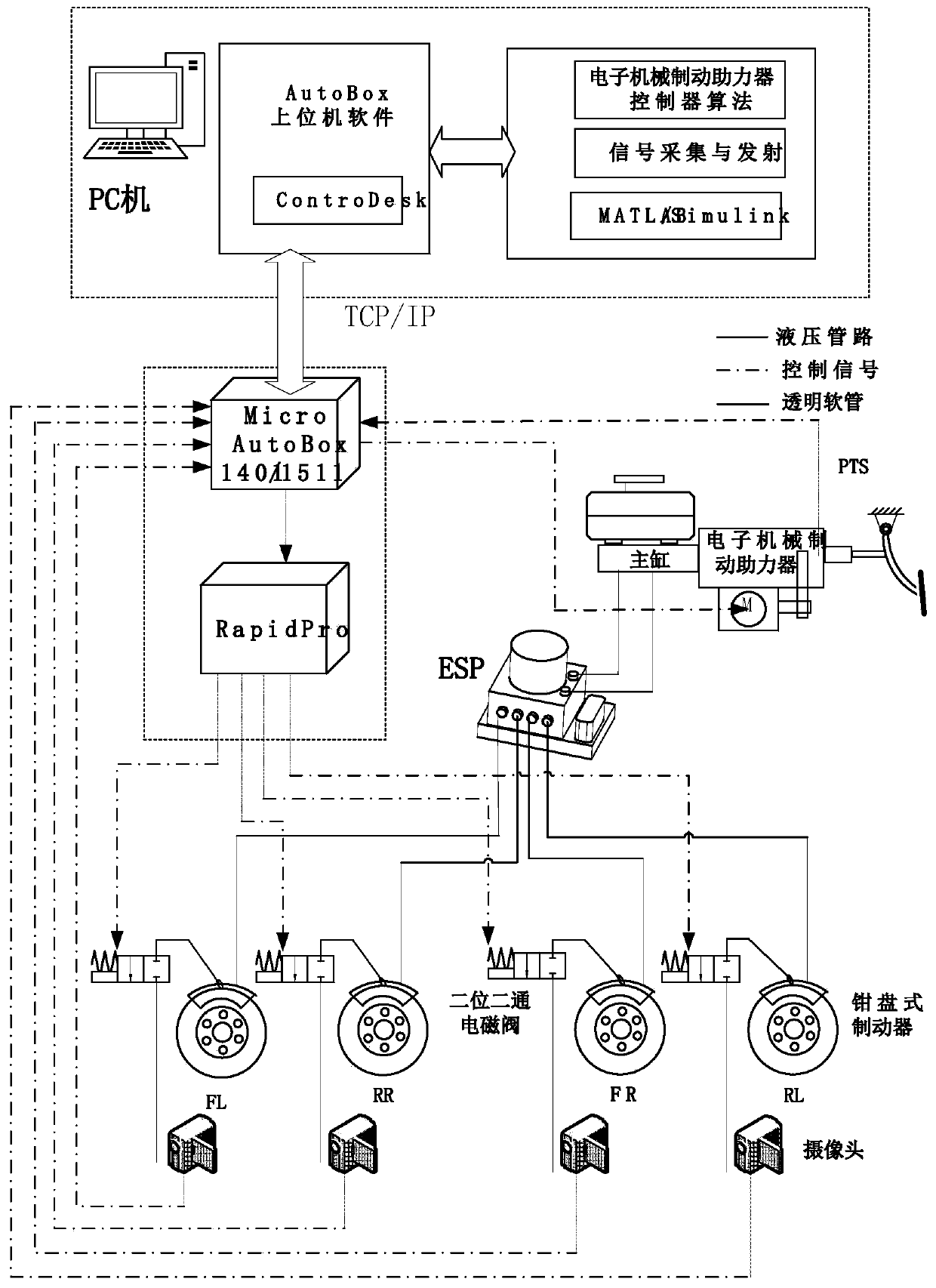

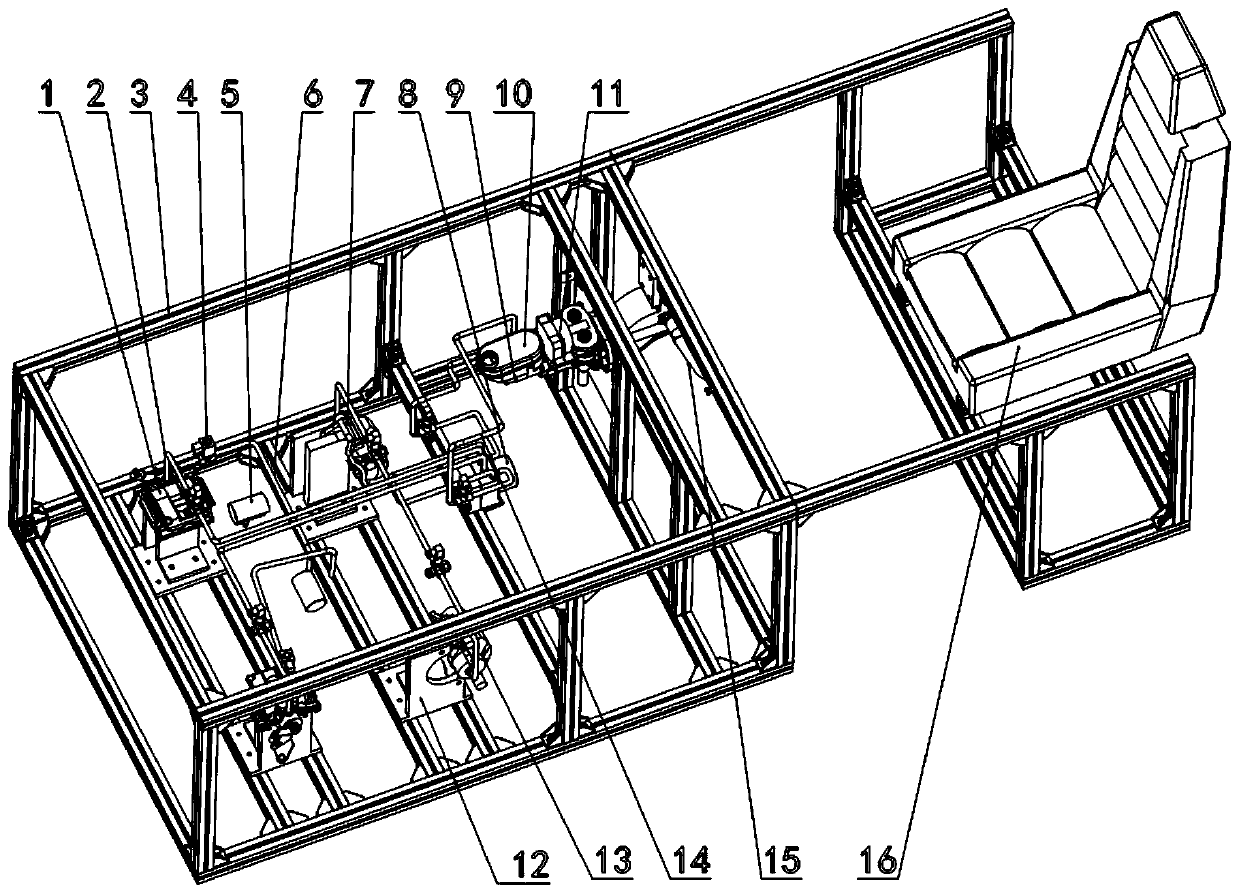

[0033] refer to figure 1 , figure 2, a hydraulic system automatic exhaust device of an electro-hydraulic brake test bench, the device includes a front brake wheel cylinder 1, a bench main body 3, a transparent hose 6, a rear brake wheel cylinder 7, and a vehicle electronic stability system 8 , brake master cylinder 9, liquid storage pot 10, electromechanical brake booster 11, support 12, brake pedal 15, adjustable seat 16, signal acquisition and launch platform, PC, two-way brake master cylinder Hydraulic pipeline 14, four two-position two-way solenoid valves 4, four caliper disc brakes 13 and four-way brake wheel cylinder hydraulic pipeline 2;

[0034] The platform main body 3 is fixed on a horizontal plane; an adjustable seat 16 is arranged at one end of the platform main body 3 ; and the support 12 is fixed on the platform main body 3 .

[0035] The electromechanical brake booster 11 is one of the control objects of the device, and the product whose publication number is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com