Electric control box cooling structure of heat pump drying unit and heat pump drying unit

A heat pump drying and cooling structure technology, applied in the direction of heat pumps, dryers, drying gas arrangement, etc., can solve problems such as corrosion, unfavorable heat dissipation of electric control boxes, generation of static electricity, etc., to prevent excessive temperature fluctuations and prevent components from running The effect of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

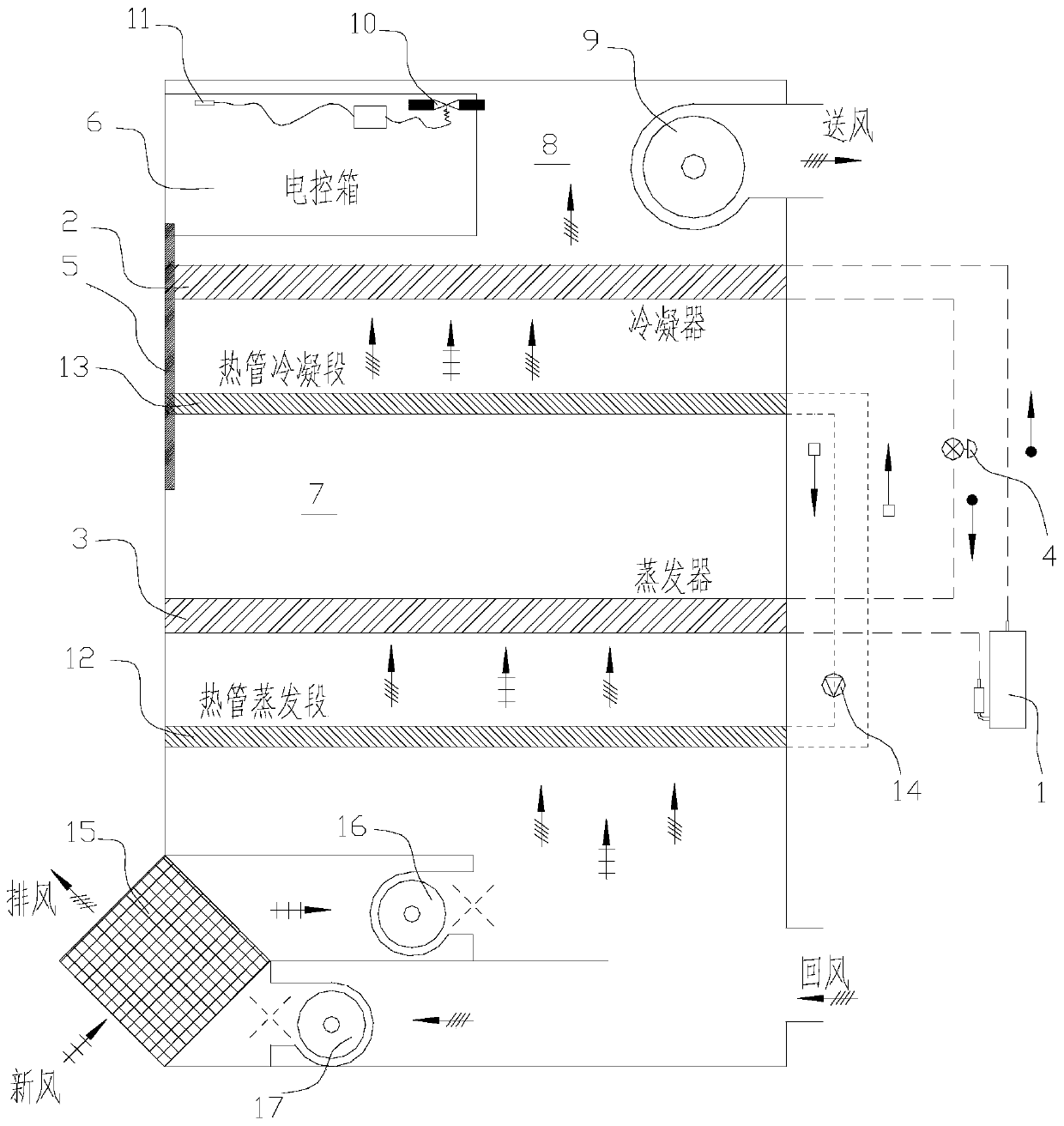

[0031] figure 1 It schematically shows a schematic diagram of the principle of the heat pump drying unit in a preferred embodiment of the present invention, and schematically shows the cooling structure of the electric control box therein.

[0032] like figure 1 As shown, the heat pump drying unit is preferably an integrated heat pump drying unit, including a heat pump system, and the heat pump system includes a compressor 1, a condenser 2, an evaporator 3 and a throttling device 4 (such as an expansion valve). During specific work, the refrigerant circulation process of the heat pump system is: compressor 1→condenser 2→throttle device 4→evaporator 3→compressor 1. Heat up. Wherein, in the air circulation direction, the evaporator 3 is arranged on the upstream side of the condenser 2 shown, so the evaporator 3 can cool and dehumidify the return air of the unit, so that it is located in the air circulation direction of the evaporator The area downstream of 3 is the dry low-te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com