A method for preparing a micron ionic crystal powder sample for scanning electron microscopy

A technology of ion crystal and scanning electron microscope, which is applied in the direction of material analysis, measuring devices, and instruments using wave/particle radiation, can solve problems such as agglomeration and agglomeration, and achieve short sample preparation cycle, tight combination, and uniform powder dispersion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

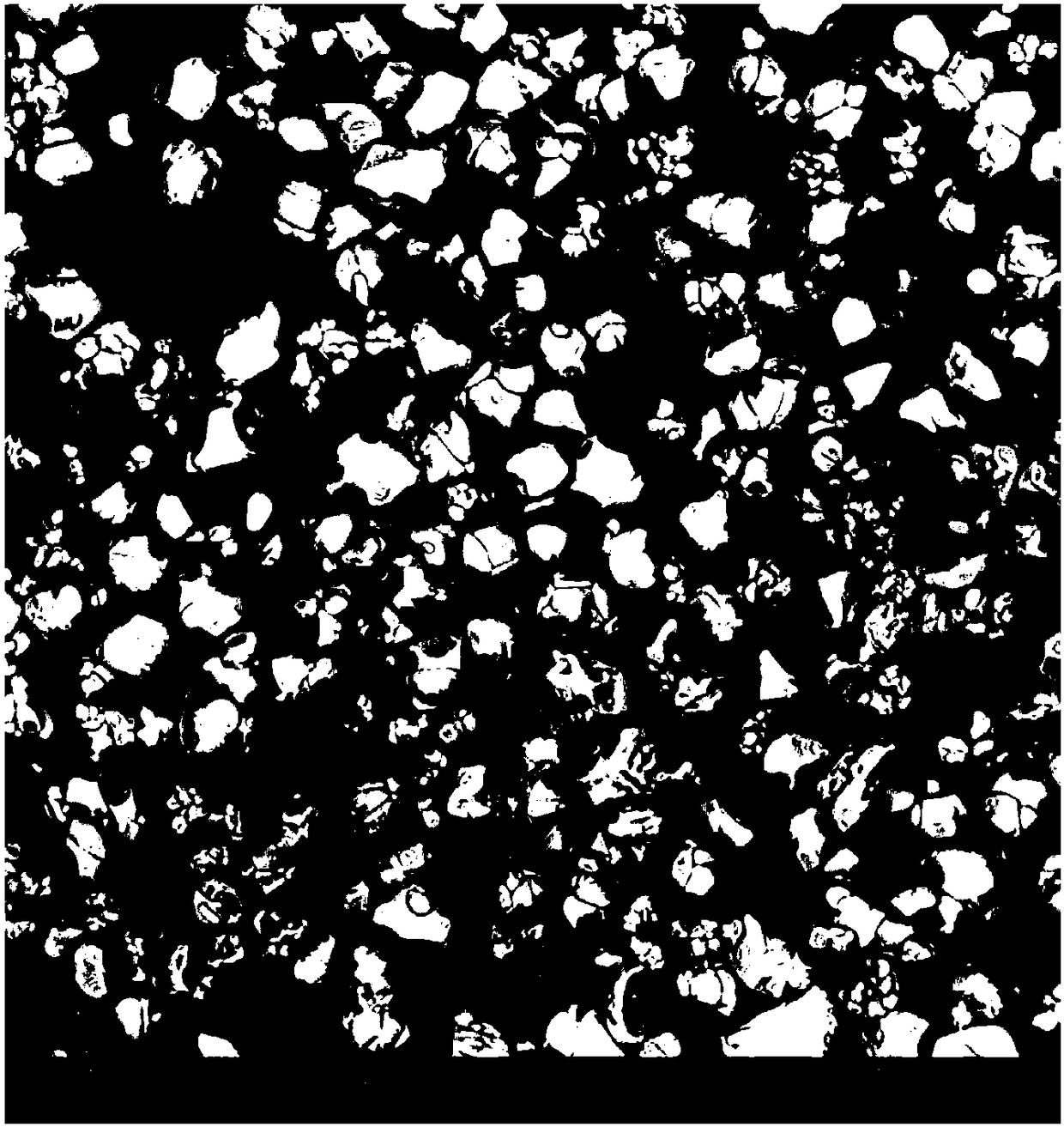

Image

Examples

Embodiment 1

[0033] A method for preparing a scanning electron microscope sample of a micron-sized ionic crystal powder, comprising the steps of:

[0034] (1) Dispersion: Take the powder sample and the dispersion liquid according to a certain proportion, add the powder sample into the dispersion liquid and stir to disperse to obtain a suspension;

[0035] (2) Sampling: Take 1-2 drops of the suspension in step (1) in the mold and volatilize at a certain temperature. After the dispersion is volatilized, the dispersed powder sample is obtained;

[0036] (3) Prepare the resin glue: blend the resin and the curing agent in a certain proportion, and stir to obtain the resin glue for curing the sample;

[0037] (4) Cold mounting sample preparation: Pour the resin glue prepared in step (3) into the mold of step (2), and let it stand at a certain temperature until the sample is solidified to obtain a metallographic sample;

[0038] (5) Gold spraying: Sputtering gold spraying on the surface of the s...

Embodiment 2

[0048] A method for preparing a scanning electron microscope sample of a micron-sized ionic crystal powder, comprising the steps of:

[0049] (1) Dispersion: Take the powder sample and the dispersion liquid according to a certain proportion, add the powder sample into the dispersion liquid and stir to disperse to obtain a suspension;

[0050] (2) Sampling: Take 1-2 drops of the suspension in step (1) in the mold and volatilize at a certain temperature. After the dispersion is volatilized, the dispersed powder sample is obtained;

[0051] (3) Prepare the resin glue: blend the resin and the curing agent in a certain proportion, and stir to obtain the resin glue for curing the sample;

[0052] (4) Cold mounting sample preparation: Pour the resin glue prepared in step (3) into the mold of step (2), and let it stand at a certain temperature until the sample is solidified to obtain a metallographic sample;

[0053] (5) Gold spraying: Sputtering gold spraying on the surface of the s...

Embodiment 3

[0062] A method for preparing a scanning electron microscope sample of a micron-sized ionic crystal powder, comprising the steps of:

[0063] (1) Dispersion: Take the powder sample and the dispersion liquid according to a certain proportion, add the powder sample into the dispersion liquid and stir to disperse to obtain a suspension;

[0064] (2) Sampling: Take 1-2 drops of the suspension in step (1) in the mold and volatilize at a certain temperature. After the dispersion is volatilized, the dispersed powder sample is obtained;

[0065] (3) Prepare the resin glue: blend the resin and the curing agent in a certain proportion, and stir to obtain the resin glue for curing the sample;

[0066] (4) Cold mounting sample preparation: Pour the resin glue prepared in step (3) into the mold of step (2), and let it stand at a certain temperature until the sample is solidified to obtain a metallographic sample;

[0067] (5) Gold spraying: Sputtering gold spraying on the surface of the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com