Auxiliary debugging method and equipment for microwave filters and storage equipment

A microwave filter and debugging method technology, which is applied to waveguide-type devices, instruments, design optimization/simulation, etc., can solve the problems of weak generalization ability, uneven distribution of matrix element values, cumbersome and other problems, so as to shorten the debugging time, The effect of improving debugging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

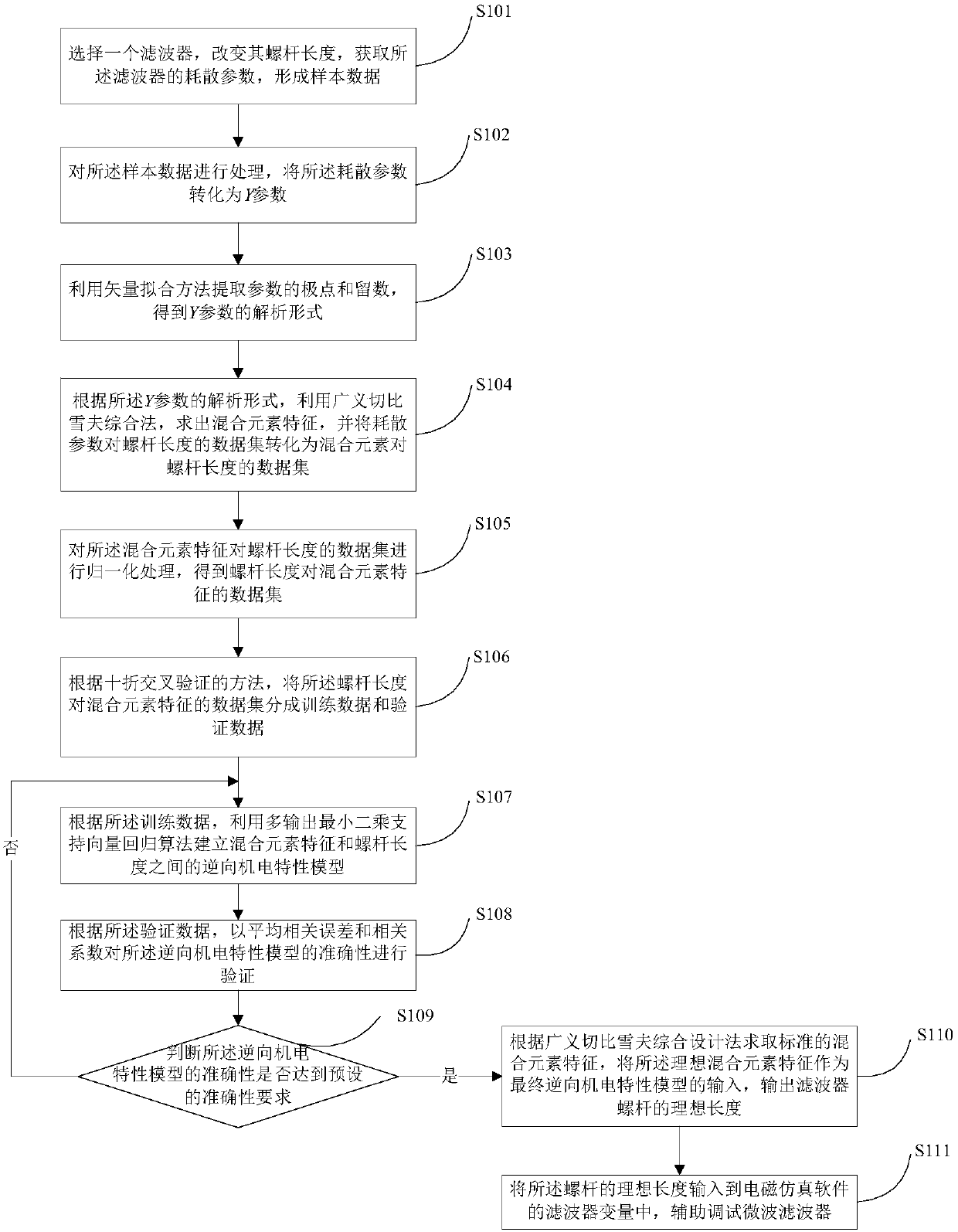

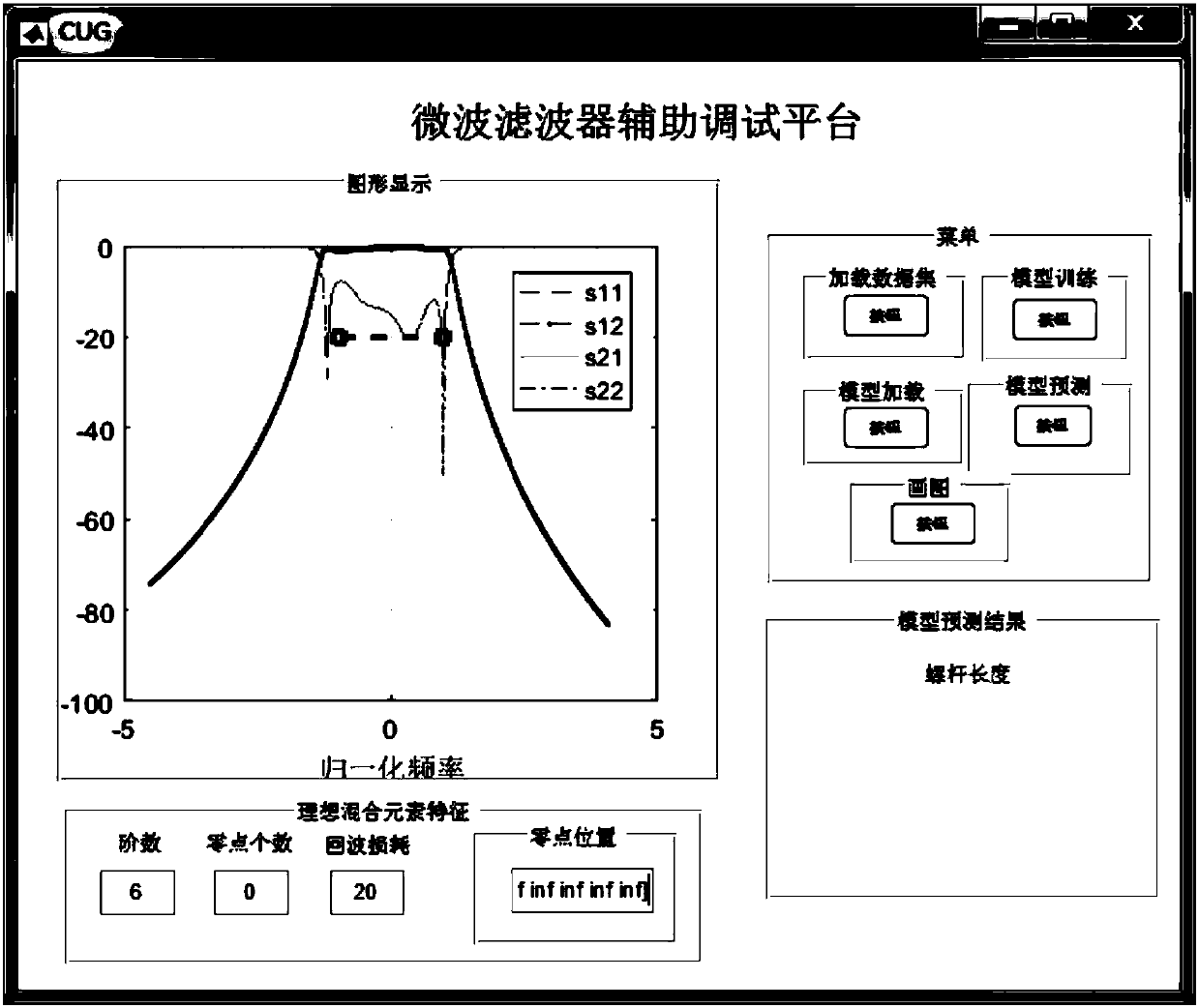

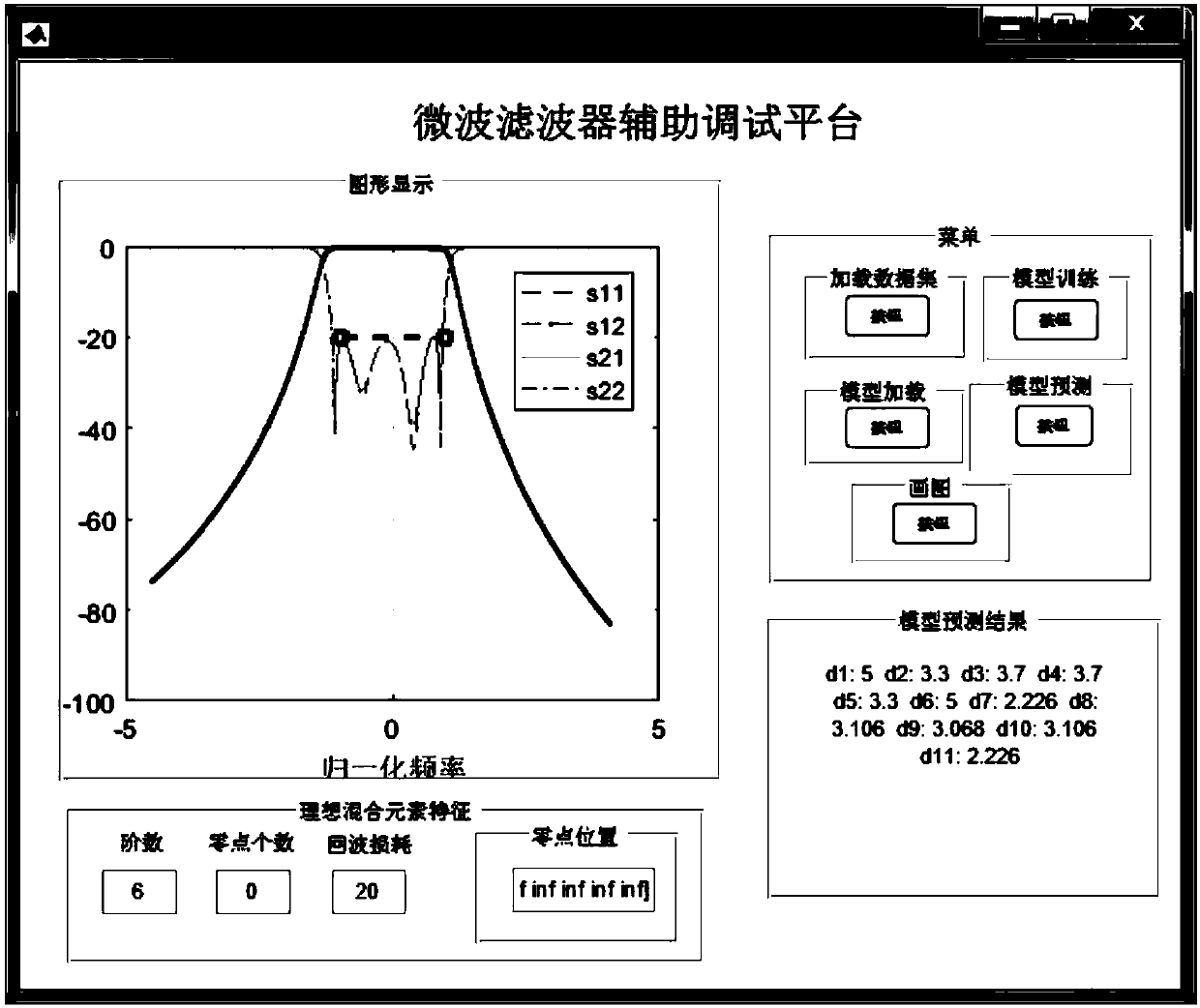

[0046] Embodiments of the present invention provide an auxiliary debugging method, device and storage device for a microwave filter with a reverse model established by mixing elements. By changing the bolt length of the microwave filter in the electromagnetic simulation software or the screw length of the actual filter, Obtain the corresponding dissipation parameter S to form a sample data set, extract the mixing elements from the dissipation parameters, and then obtain the data set Data between the characteristics of the mixing elements and the length of the screw, and then establish the characteristics of the mixing elements and the screw length by training the data set. Inverse electromechanical behavior model D betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com