Moxibustion device

The technology of a moxibustion device and a fixed part is applied in the field of health care products, which can solve the problems of choking, easy generation of smoke, and dependence on manual work, and achieves the effects of convenient manufacture and use, reducing the amount of smoke generated, and prolonging the replacement cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

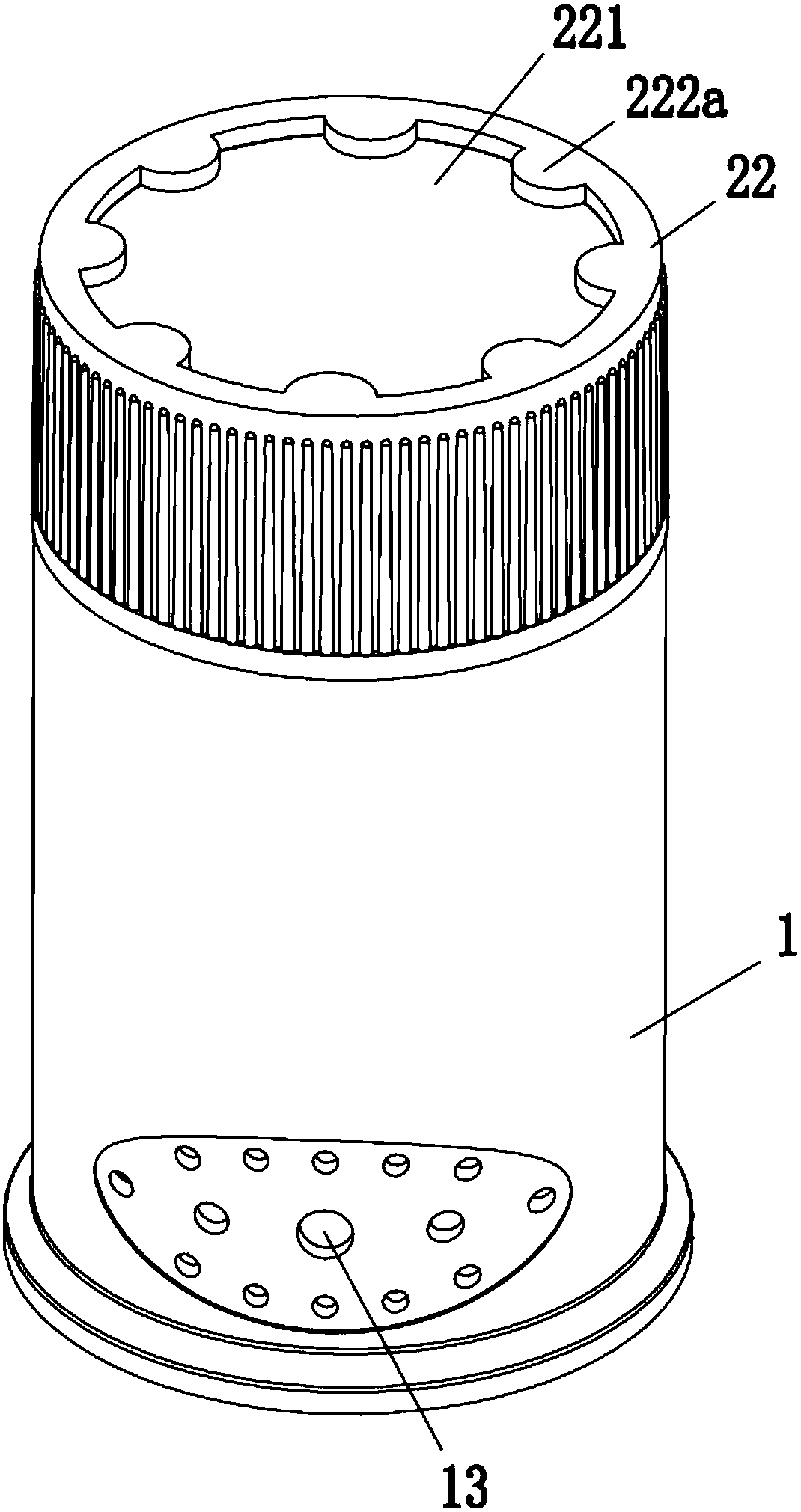

[0062] As shown in the figure, a moxibustion device is composed of a fixed part 1 and a movable part 2 as a whole. The fixed part 1 and the movable part 2 are matched by a lifting device. The threads and thread grooves on the inner wall of the part 2, so that the movable part 2 can be screwed in or out relative to the fixed part 1, and the interference fit between the threads and the thread grooves makes the movable part 2 unable to move under the action of gravity relative to the fixed part 1. Accidental screwing in or out occurs.

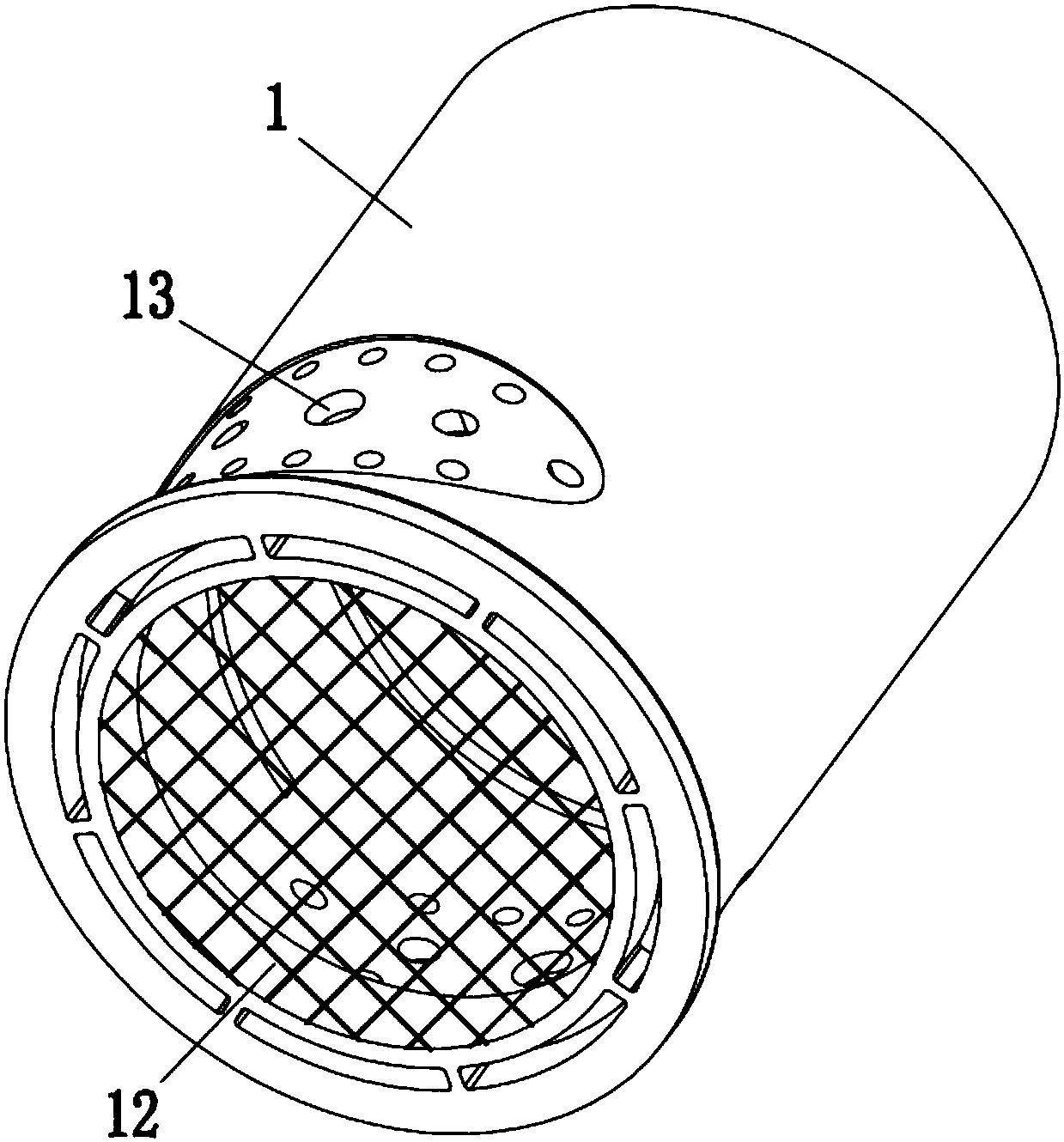

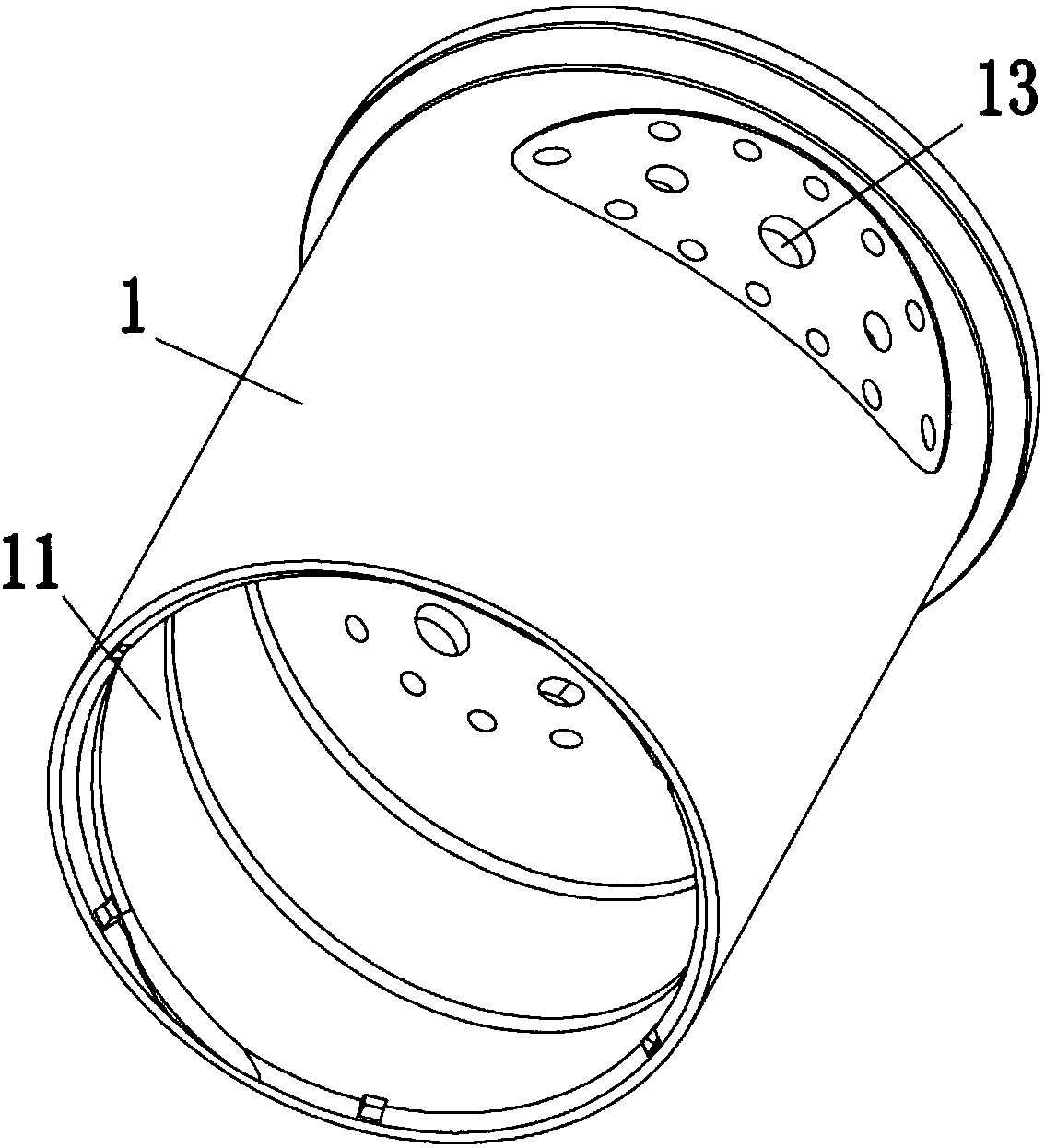

[0063] The fixed part 1 is provided with a first accommodating space 11 for the movable part 2, and a filter screen 12 is provided at the bottom of the first accommodating space 11, and the filter screen 12 is made of aluminum or stainless steel to prevent moxa sticks from burning. For burns caused by hot ash falling, the side wall of the fixed part 1 is also provided with a vent 13 so that the first accommodation space 11 can communicate with the...

Embodiment 2

[0069] On the basis of Example 1, Example 2 further uses the special smokeless moxa column of the present invention to further reduce the smoke generated during the burning process of the moxa column. The smokeless moxa column is composed of the following components in mass fraction: moxa 80wt%, moxa 15wt%, calcium peroxide 1wt% and binder 4%.

[0070] Mugwort is made from fresh mugwort leaves after picking, drying and mashing, while moxa charcoal is prepared according to the following steps:

[0071] The steps of pretreatment: the rhizome of wormwood is washed and dried for later use;

[0072] Step of pre-sintering: put the pretreated rhizomes of wormwood in a sintering furnace, and pre-sinter at 1000° C. for 3 hours;

[0073] Sintering and carbonization steps: compact the pre-sintered coarse material, seal the sintering furnace, replace the sintering atmosphere with nitrogen, sinter and carbonize at 1500°C for 10 hours, and then cool naturally to room temperature;

[0074]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com