A kind of high-speed vcp copper plating additive and preparation method thereof

An additive and high-speed technology, applied in the field of high-speed VCP copper plating additives and its preparation, can solve the problems of poor plating uniformity, maximizing current density, and affecting productivity in the gantry line plating process, and achieve shortened plating time, excellent uniformity, and uniformity. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

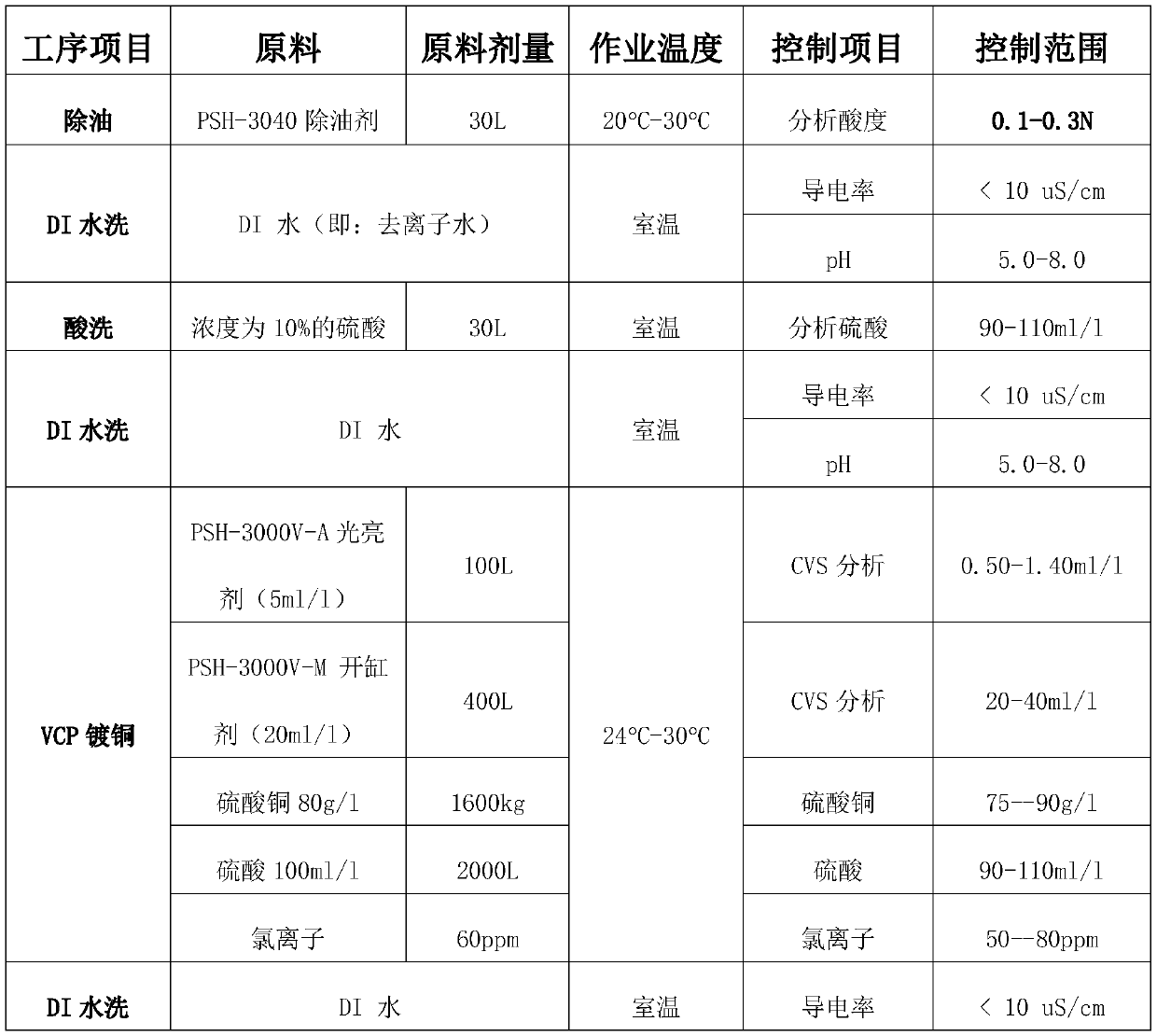

Method used

Image

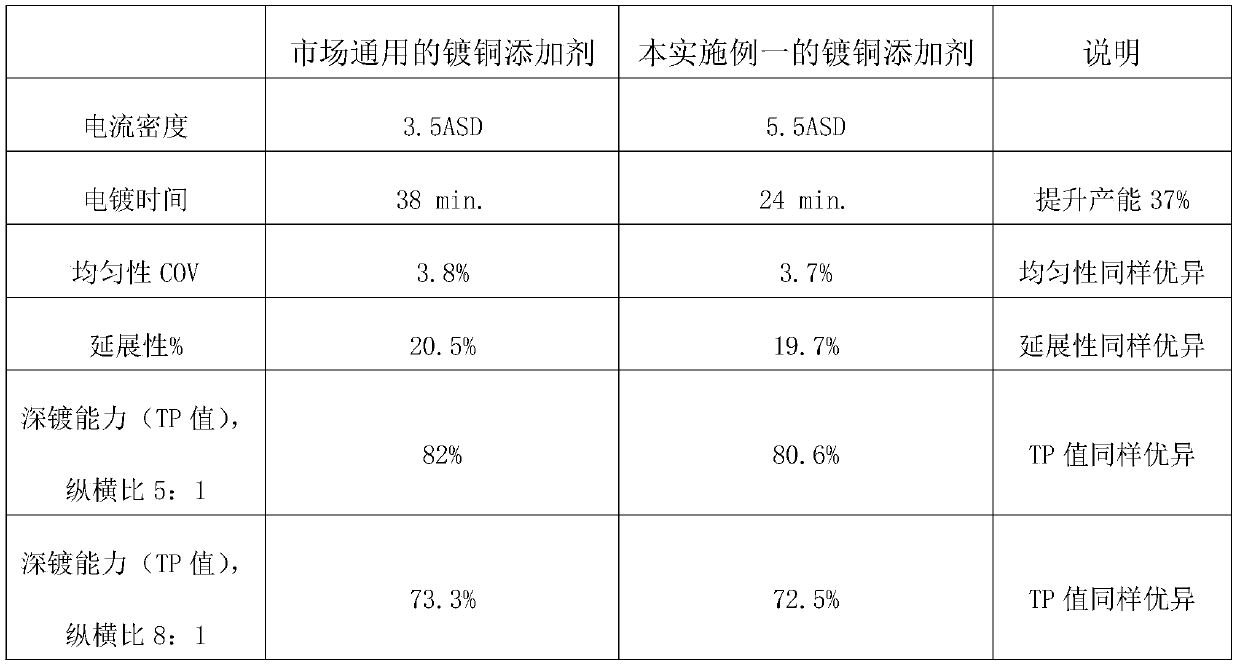

Examples

Embodiment 1

[0023] S1. Mix and stir 3 kg of water-soluble polyethylene glycol with a molecular weight of 10000-20000 and 43 kg of water until the polyethylene glycol is completely dissolved to obtain a primary mixture;

[0024] S2. Add 0.1kg of 2-picolinic acid into the primary mixture and mix and stir until the 2-picolinic acid is completely dissolved to obtain the secondary mixture;

[0025] S3, adding 10 kg of polyethylene glycol to polypropylene glycol in the ratio of 3:1 polyethylene glycol polypropylene glycol copolymer to the secondary mixture for mixing and stirring until the polyethylene glycol polypropylene glycol copolymer is completely dissolved to obtain a third mixture ;

[0026] S4. Add 0.2kg of quaternized polyvinylimidazole into the three mixtures and mix and stir until the polyvinylimidazole is completely dissolved to obtain the four mixtures;

[0027] S5. Add 0.4kg sodium dimethylformamidopropane sulfonate to the mixture for four times and mix and stir until the sodium...

Embodiment 2

[0030] S1. Mix and stir 5 kg of water-soluble polyethylene glycol with a molecular weight of 10000-20000 and 46 kg of water until the polyethylene glycol is completely dissolved to obtain a primary mixture;

[0031] S2. Add 0.3kg of 2-picolinic acid into the primary mixture and mix and stir until the 2-picolinic acid is completely dissolved to obtain the secondary mixture;

[0032] S3. Add 5 kg of polyethylene glycol-polypropylene glycol copolymer with a ratio of 3:1 to polypropylene glycol to the secondary mixture and mix and stir until the polyethylene glycol-polypropylene glycol copolymer is completely dissolved to obtain a tertiary mixture ;

[0033] S4. Add 0.3kg of quaternized polyvinylimidazole into the three mixtures and mix and stir until the polyvinylimidazole is completely dissolved to obtain the four mixtures;

[0034] S5. Add 0.6kg sodium dimethylformamidopropane sulfonate into the mixture for four times and mix and stir until the sodium dimethylformamidopropane ...

Embodiment 3

[0037] S1. Mix and stir 2 kg of water-soluble polyethylene glycol with a molecular weight of 10000-20000 and 37 kg of water until the polyethylene glycol is completely dissolved to obtain a primary mixture;

[0038] S2. Add 0.1kg of 2-picolinic acid into the primary mixture and mix and stir until the 2-picolinic acid is completely dissolved to obtain the secondary mixture;

[0039] S3. Add 8 kg of polyethylene glycol-polypropylene glycol copolymer with a ratio of 3:1 to polypropylene glycol to the secondary mixture and mix and stir until the polyethylene glycol-polypropylene glycol copolymer is completely dissolved to obtain a three-time mixture ;

[0040] S4. Add 0.1kg of quaternized polyvinylimidazole to the three mixtures and mix and stir until the polyvinylimidazole is completely dissolved to obtain the four mixtures;

[0041] S5. Add 0.2kg sodium dimethylformamidopropane sulfonate to the mixture for four times and mix and stir until the sodium dimethylformamidopropane su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com