Method and device for determining self-resetting temperature of equipment

A self-reset and equipment technology, applied in mechanical equipment, monitoring of wind turbines, wind turbines, etc., can solve the problems of inability to properly set the self-reset temperature, inability to effectively reset the wind turbine, and loss of power generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

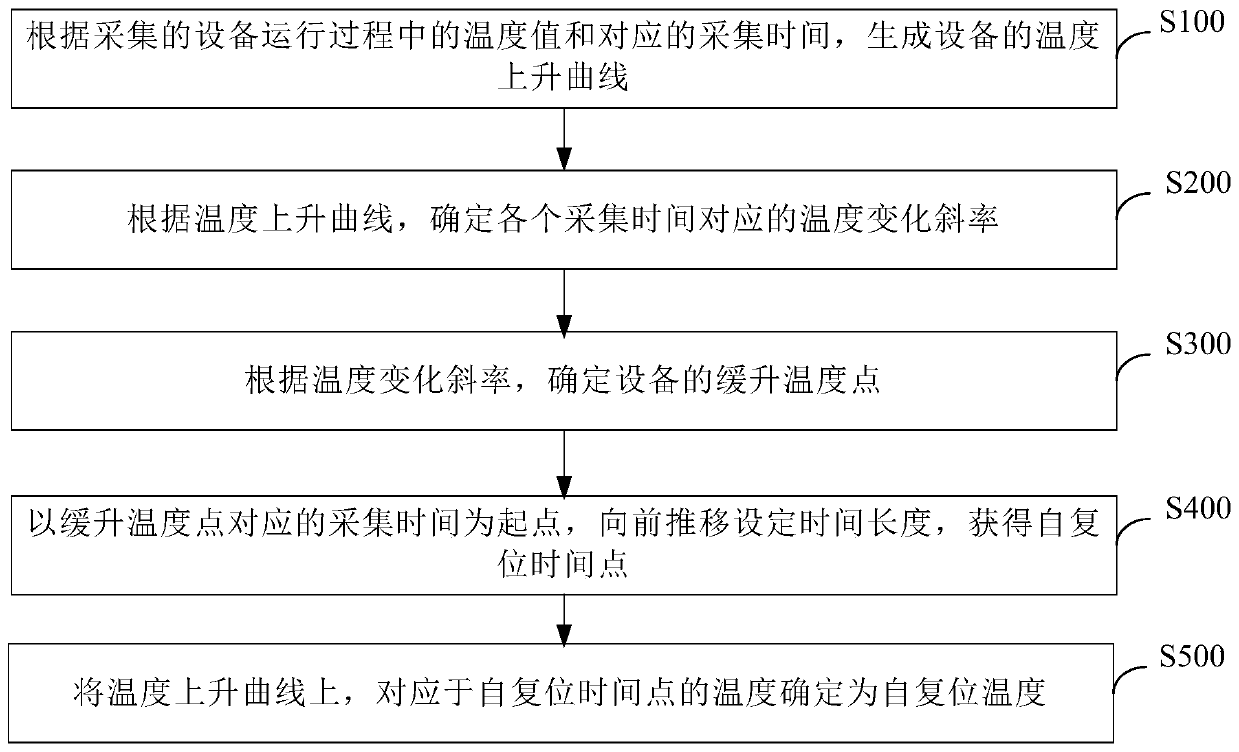

[0023] refer to figure 1 , shows a flowchart of steps of a method for determining the self-resetting temperature of a device according to Embodiment 1 of the present invention.

[0024] The method for determining the self-resetting temperature of the device in this embodiment includes the following steps:

[0025] S100: Generate a temperature rise curve of the device according to the collected temperature value during the operation of the device and the corresponding collection time.

[0026] The collection of temperature values during equipment operation is flexibly determined by those skilled in the art according to actual needs, for example, once a quarter, or once a month, or once a day, or once during the day and once at night, or during the day Acquisition and the like are performed when needed, which is not limited in this embodiment of the present invention.

[0027] S200: Determine the temperature change slope corresponding to each collection time according to the...

Embodiment 2

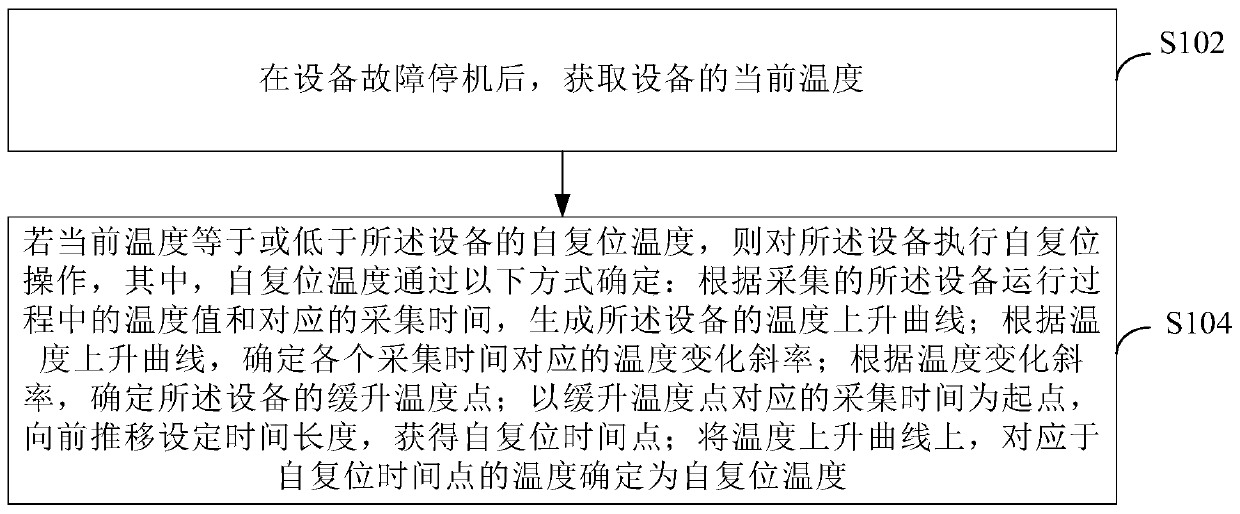

[0037] refer to figure 2 , shows a flow chart of steps of a device self-resetting method according to Embodiment 2 of the present invention.

[0038] In this embodiment, taking the application of the determined self-resetting temperature of the device in actual industrial control as an example, the scheme for determining the self-resetting temperature of the device provided in the embodiment of the present invention is described.

[0039] The device self-resetting method in this embodiment includes the following steps:

[0040] S102: Obtain the current temperature of the device after the device is shut down due to failure.

[0041] Taking a wind generator as an example, the equipment includes but is not limited to: generator windings, main bearings, gear bearings, gearboxes, pitch motors, control cabinets, nacelles, frequency converters, etc. of the wind generator.

[0042] In the embodiment of the present invention, the equipment failure shutdown mainly includes the failur...

Embodiment 3

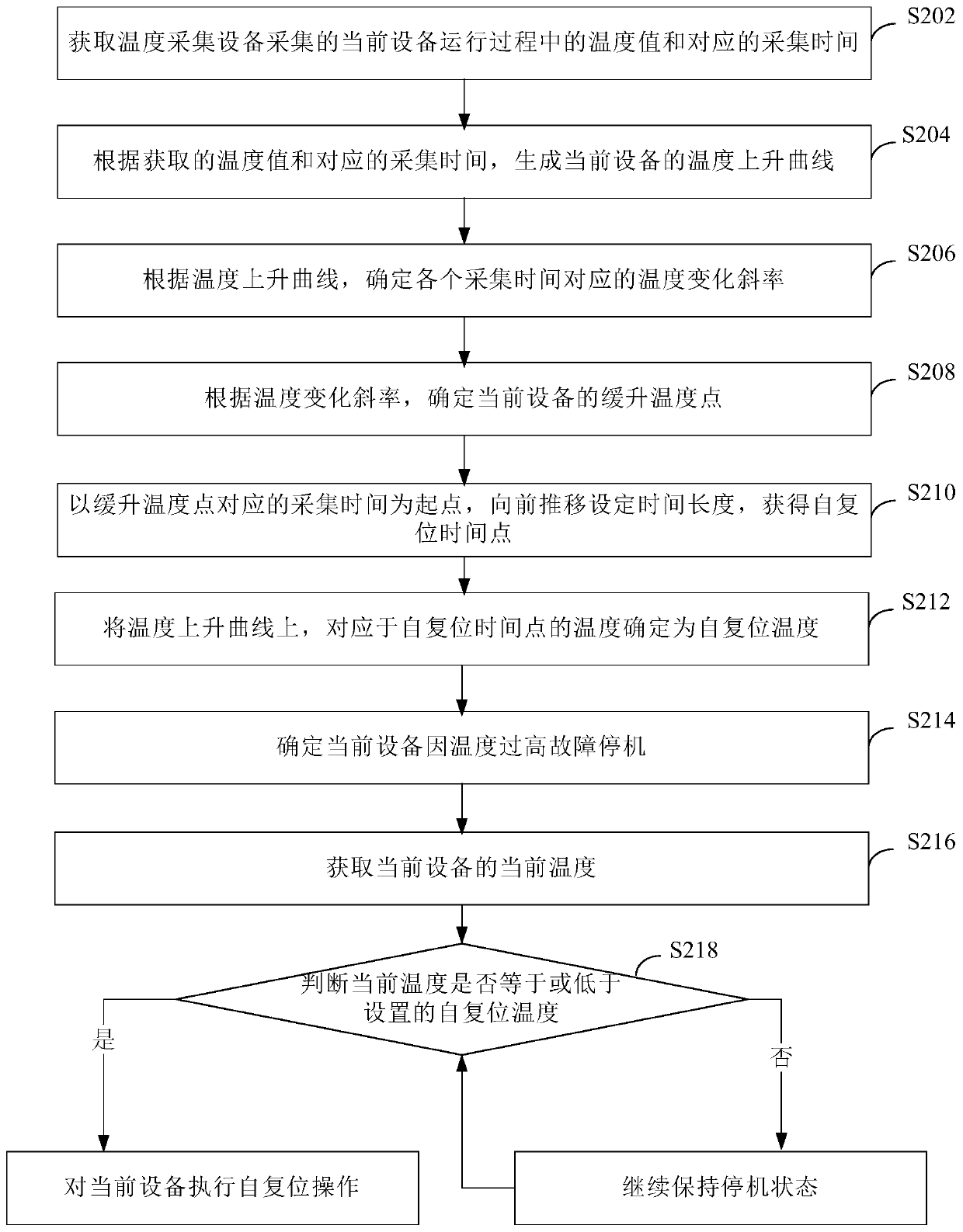

[0051] refer to image 3 , shows a flowchart of steps of a device self-resetting method according to Embodiment 3 of the present invention.

[0052] This embodiment describes the solution provided by the embodiment of the present invention in combination with the determination of the self-resetting temperature of the device and its application in actual industrial control.

[0053] The device self-resetting method in this embodiment includes the following steps:

[0054] S202: Obtain the temperature value collected by the temperature collection device during the current device operation and the corresponding collection time.

[0055] As described in Embodiments 1 and 2, the acquisition timing can be set by those skilled in the art according to actual needs. In addition, the collection period can also be set by those skilled in the art according to actual needs, such as collecting once at a set time interval or collecting in real time, which is not limited in the embodiments ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com