Measurement method for battery welding quality

A technology of welding quality and measurement method, applied in the direction of material resistance, etc., can solve the problem of battery secondary damage accuracy, etc., and achieve the effect of rapid measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

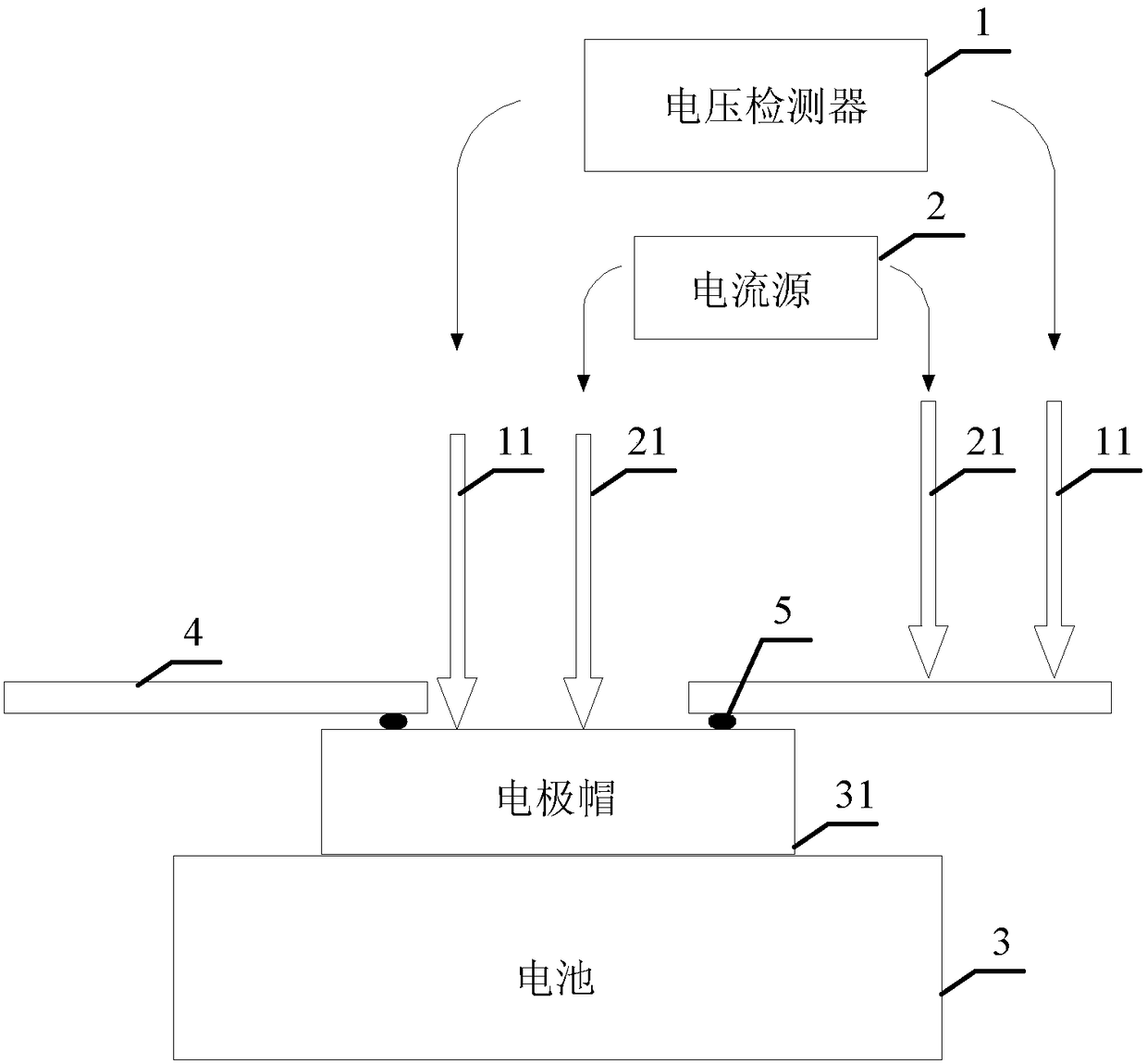

Method used

Image

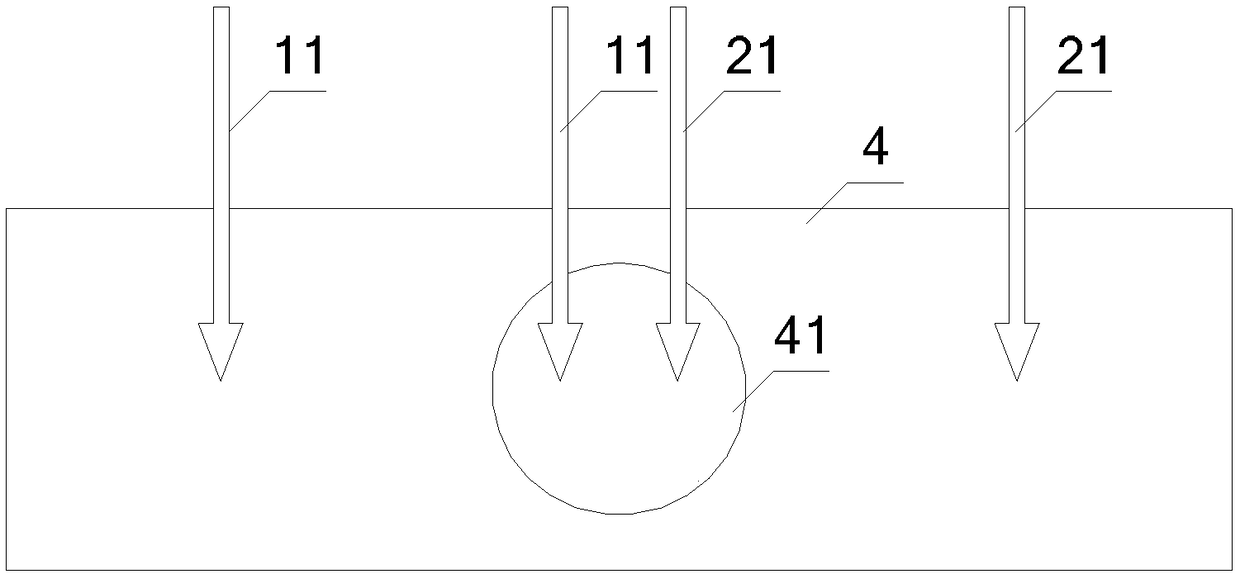

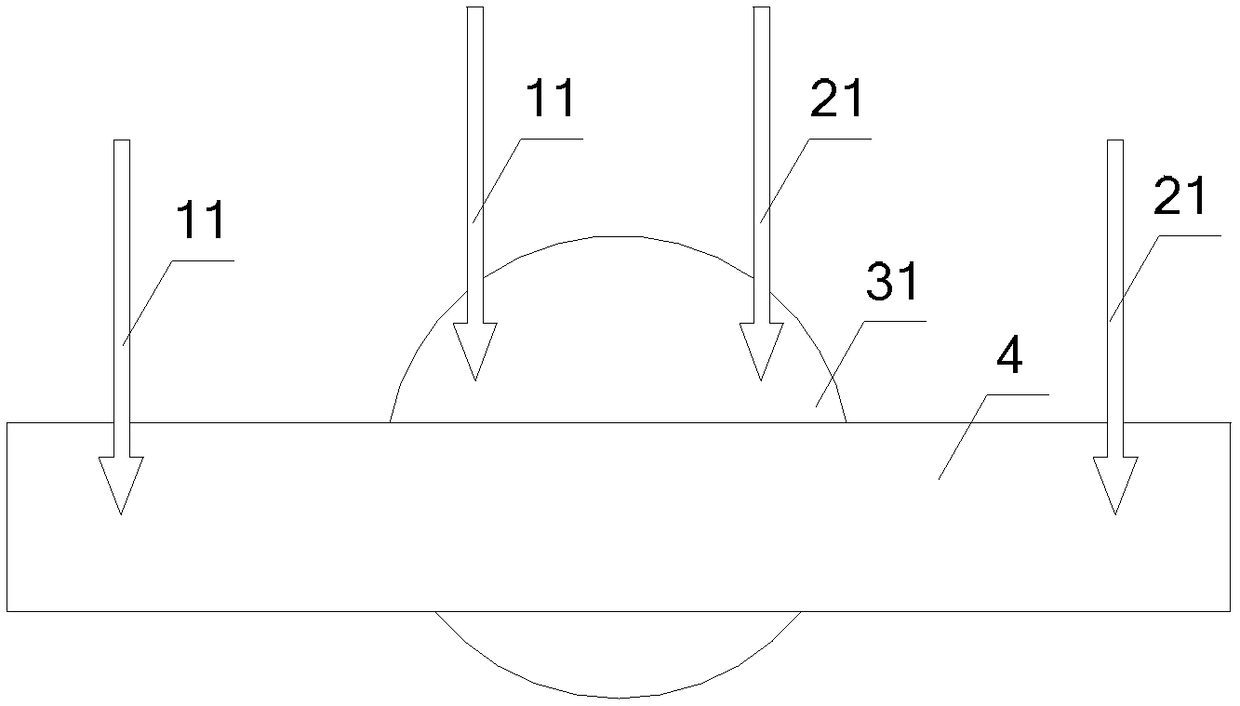

Examples

specific Embodiment

[0026] In this embodiment, the battery adopts a 18650 type lithium iron phosphate 1.5Ah / 3.2V single battery, and its electrode cap is circular with a diameter of 12 mm and a flat surface. The voltage detector is a voltage detection device that receives the signal from the controller and collects the voltage V ad . Specifically, this embodiment adopts ADI's high-speed analog-to-digital converter AD9220 to realize signal acquisition. The maximum sampling rate of AD9220 can reach 10 MHz, and an external crystal oscillator of 8 MHz is used to realize signal storage through sampling inside the FPGA. The voltage signal of the battery module can be collected and converted into a digital signal for output. The current source adopts ZM20-12ET switch type controlled DC constant current power supply, the controlled output current range is 1-10A, the maximum output voltage is limited to 3V, and the current accuracy is 0.2%. It can accept the control signal of the controller and accuratel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com