Vertical swirl split-phase capacitance integrated water content measurement device

A measuring device, an integrated technology, applied in the direction of measuring devices, material capacitance, analysis materials, etc., can solve the problems of growth, inability to guarantee the stability of gas-liquid two-phase flow form, long overall structure, etc., and achieve high capacitance measurement accuracy, Good water content measurement accuracy and the effect of shortening the structure length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below with reference to the accompanying drawings.

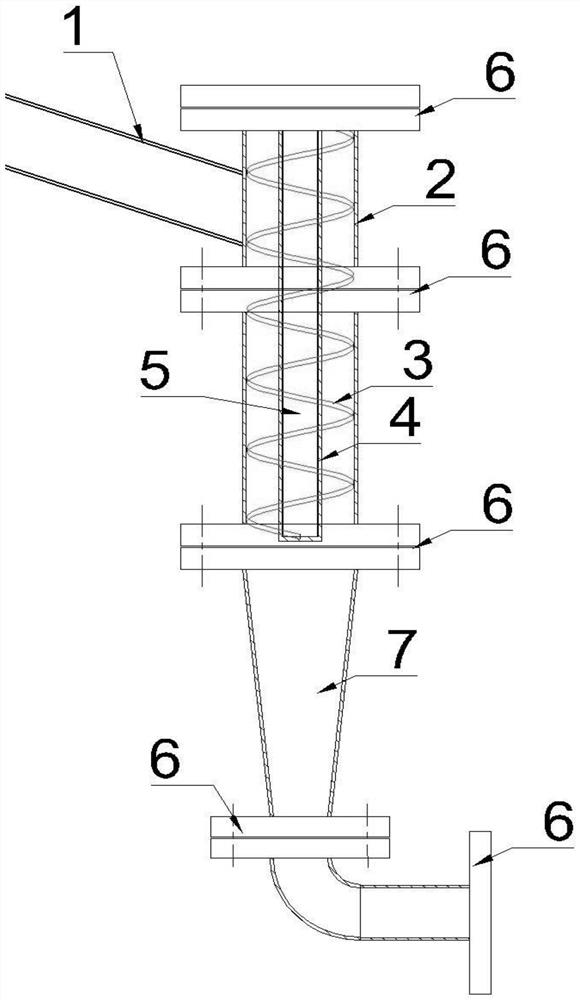

[0027] The present invention is a moisture content measuring device used in wet gas two-phase flow, the structural diagram is as follows figure 1 shown. It can be used in conjunction with any gas flow measuring device, such as orifice plate, Venturi, nozzle, V-cone and other throttling devices and ultrasonic, turbine, thermal and other flow meters.

[0028] The present invention is different from the conventional moisture content measuring device in that the electric capacity is measured while the gas-liquid two-phase is swirled and phase-separated. Such as figure 1 As shown, the gas-liquid two-phase flows tangentially into the swirl phase separation section through the inclined inlet 1. In order to realize the fluid flow without resistance, the inlet inclination angle is the same as the helical blade 3 elevation angle of 10° to 50°, and at the same time, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com