Cooling structure for direct-current superconducting current limiter and assembling method thereof

A technology of superconducting current limiter and cooling structure, applied in superconducting magnets/coils, emergency protection circuit devices for limiting overcurrent/overvoltage, circuit devices, etc., can solve the problem that DC withstand voltage cannot meet system requirements, etc. problem, to avoid bubble discharge phenomenon, facilitate heat dissipation, and facilitate installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

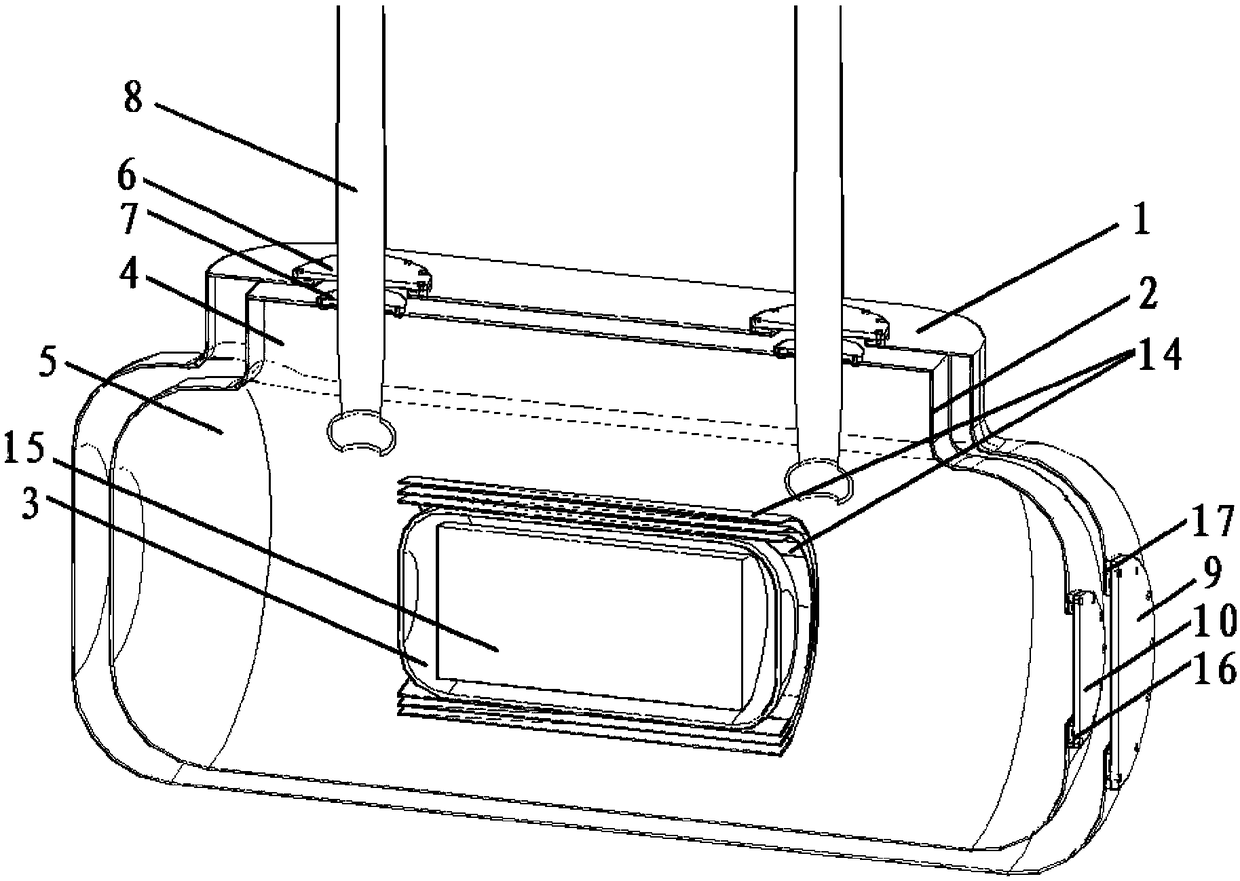

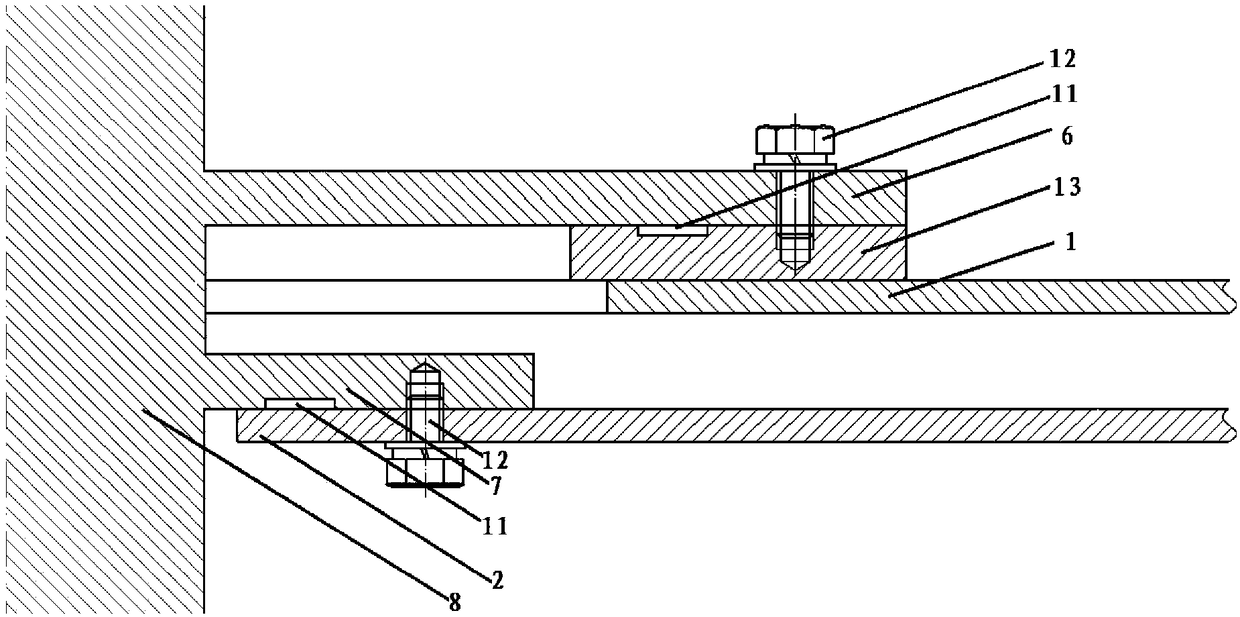

[0032] Such as figure 1 As shown, a cooling structure for a DC superconducting current limiter of the present invention includes a double-layer vacuumized structure formed by a tank body 5 and an inlet and outlet line part 4 connected to the upper part of the tank body 5, and a magnet is placed in the inner layer of the double-layer vacuumized structure 15 and the cooling liquid, the interlayer is a vacuum layer, the manhole is located at the end of one side of the tank body 5, and the connection between the tank body 5 and the inlet and outlet part 4 adopts chamfers.

[0033] In this embodiment, in order to avoid sharp discharges, the connecting parts of the tank body 5 and the inlet and outlet parts 4 adopt chamfered corners.

[0034] The inner layer 2 of the double-layer vacuum structure is also provided with a magnet 15, a shielding shell 3 and an insulating cardboard 14, wherein the shielding shell 3 is a structure that cooperates with the magnet 15, and its upper part is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com