High-oxidation-stability oil-in-water emulsion and preparation method thereof

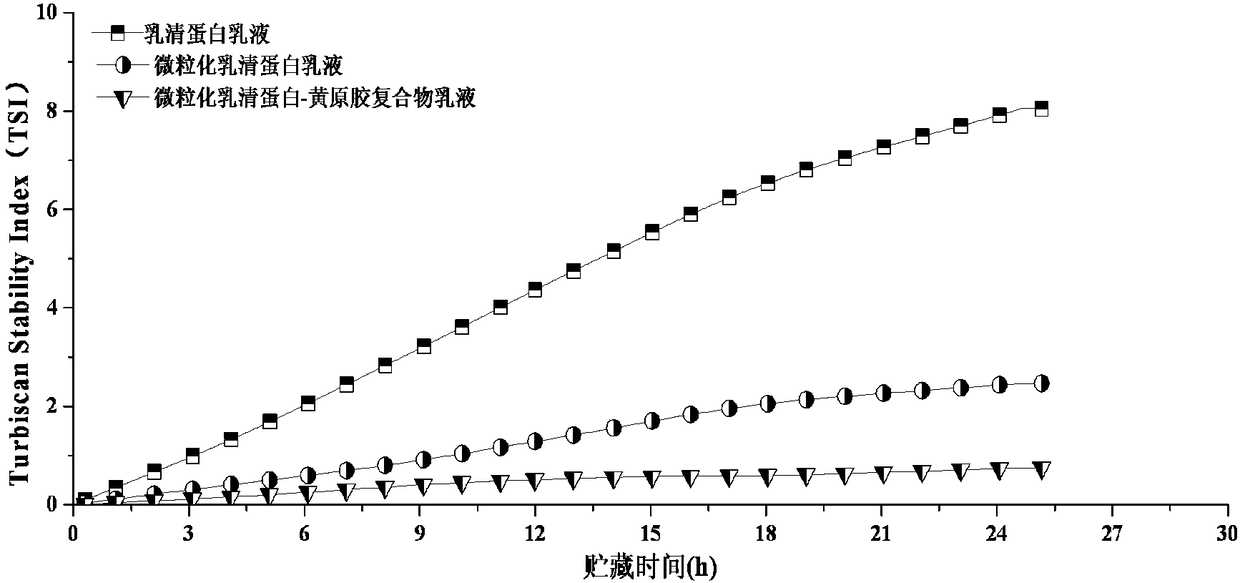

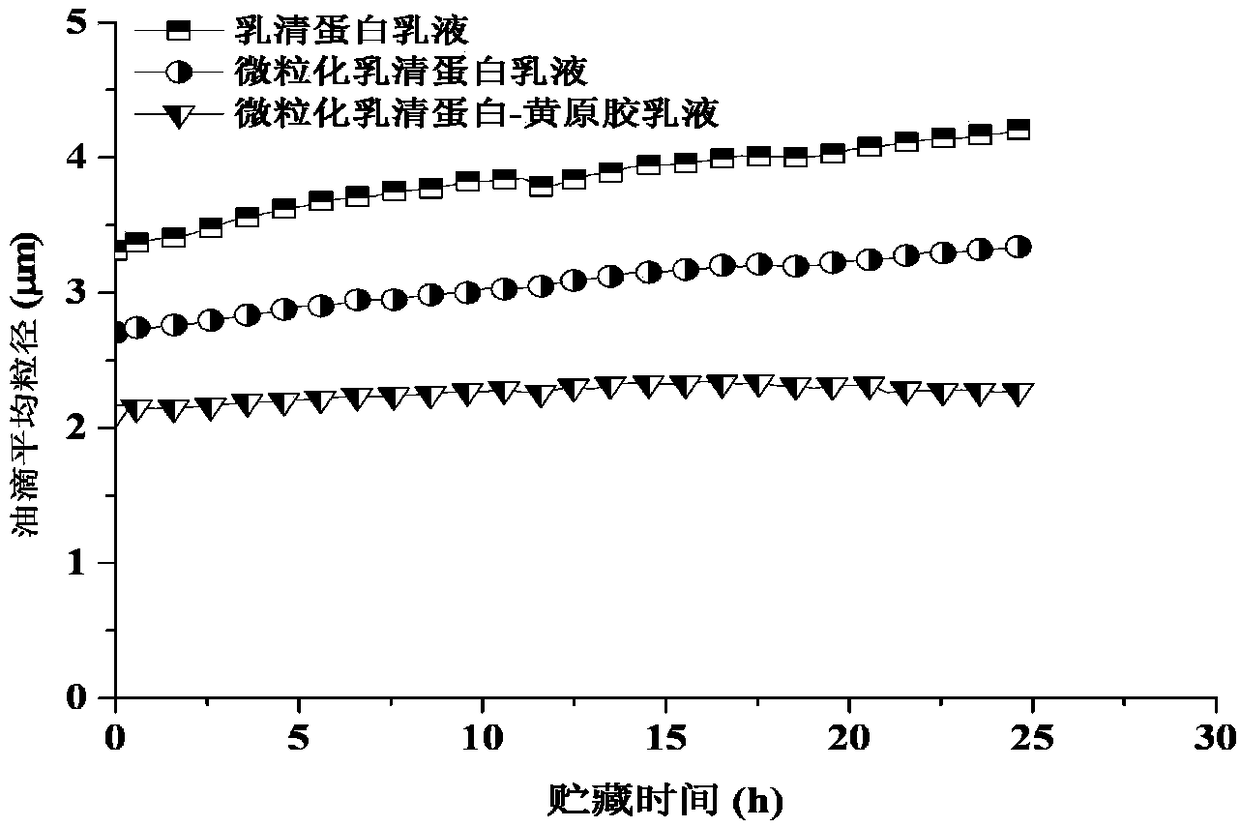

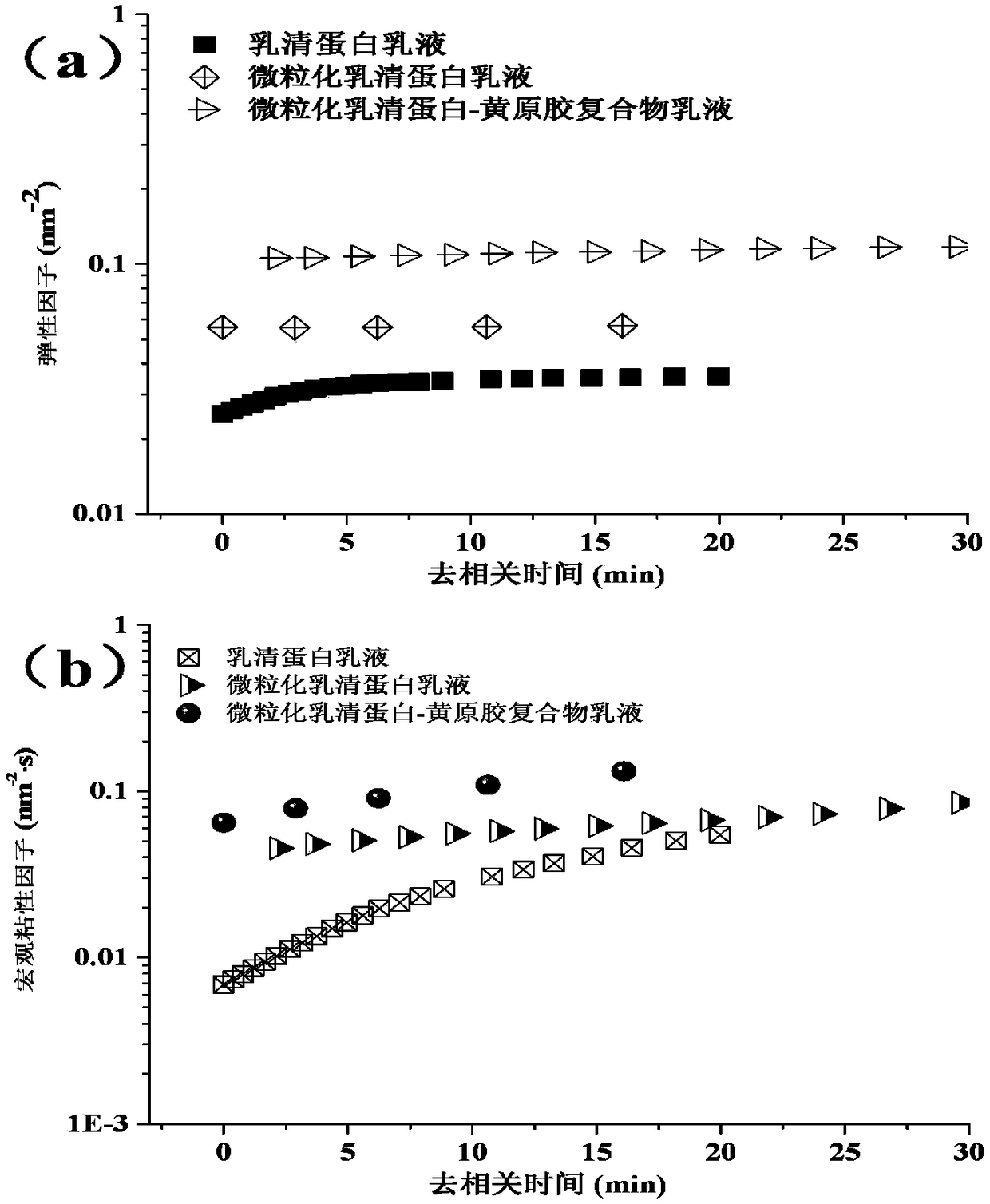

An oil-in-water emulsion, high oxidative stability technology, used in the production/processing of edible oil/fat components, edible oil/fat, etc., can solve problems such as poor oxidative stability, achieve natural raw materials, good application prospects, The effect of high physical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] An oil-in-water emulsion with high oxidation stability, its composition and parts by weight are as follows:

[0040] Micronized whey protein dispersion: 50 parts;

[0041] Xanthan gum system: 20 parts;

[0042] Oil phase: 30 parts.

[0043] The preparation method of the above-mentioned high oxidation stability oil-in-water emulsion, the steps are as follows:

[0044] (1) Preparation of micronized whey protein dispersion: Dissolve whey protein powder in water to obtain a whey protein dispersion with a concentration of 0.15 g / mL, adjust the pH to 6.5; minute, cooled to room temperature, and then placed at 10°C for 15 hours to obtain whey protein gel; micronized whey protein gel obtained by aging at 10,000 r / min for 3 minutes to obtain micronized whey protein dispersion.

[0045] (2) Preparation of xanthan gum system: mix xanthan gum and water at a mass ratio of 1:25, heat-treat at 75°C for 40 minutes, and stir evenly to obtain the xanthan gum system.

[0046](3) Prep...

Embodiment 2

[0049] An oil-in-water emulsion with high oxidation stability, its composition and parts by weight are as follows:

[0050] Micronized whey protein dispersion: 70 parts;

[0051] Xanthan gum system: 10 parts;

[0052] Oil phase: 20 parts.

[0053] The preparation method of the O / W type emulsion of above-mentioned high oxidation stability, the steps are as follows:

[0054] (1) Preparation of micronized whey protein dispersion: dissolve whey protein powder in water to obtain a whey protein dispersion with a concentration of 0.10 g / mL, adjust the pH to 4.0; Minutes, cooled to room temperature, and then placed at 4°C for 10 hours to obtain whey protein gel; micronized whey protein gel obtained by aging at 12000r / min for 6 minutes to obtain micronized whey protein dispersion.

[0055] (2) Preparation of xanthan gum system: mix xanthan gum and water at a mass ratio of 1:30, heat-treat at 90°C for 20 minutes, and stir evenly to obtain the xanthan gum system.

[0056] (3) Prepar...

Embodiment 3

[0059] An oil-in-water emulsion with high oxidation stability, its composition and parts by weight are as follows:

[0060] Micronized whey protein dispersion: 20 parts;

[0061] Xanthan gum system: 30 parts;

[0062] Oil phase: 50 parts.

[0063] The preparation method of the above-mentioned high oxidation stability oil-in-water emulsion, the steps are as follows:

[0064] (1) Preparation of micronized whey protein dispersion: Dissolve whey protein powder in water to obtain a whey protein dispersion with a concentration of 0.12 g / mL, and adjust the pH to 5.0; heat and moisten it in a constant temperature water bath at 95°C for 10 minutes , cooled to room temperature, and then placed at 3°C for 10 hours to obtain whey protein gel; micronized whey protein gel obtained by aging at 15000r / min for 9 minutes to obtain micronized whey protein Dispersions.

[0065] (2) Preparation of xanthan gum system: mix xanthan gum and water at a mass ratio of 1:35, heat-treat at 100°C for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com