Sand core with specific exhaust structure, and preparation method thereof

A sand core and a specific technology, applied in the field of sand core and its preparation, can solve the problems of complex and unstable exhaust structure of the sand core, and achieve the effects of remarkable exhaust effect, increased exhaust effect, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

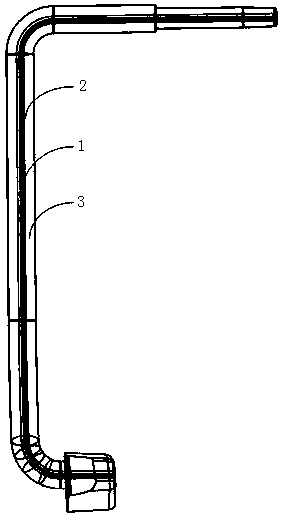

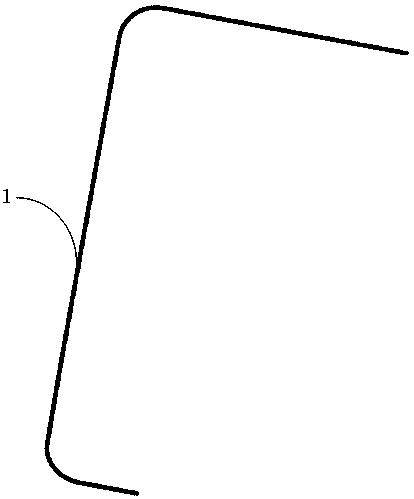

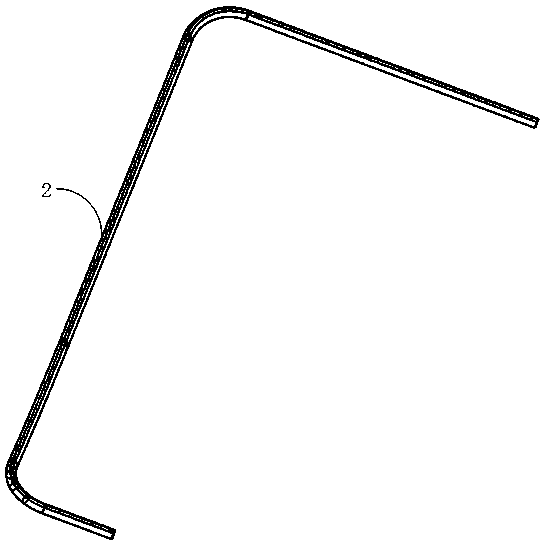

[0032] The invention provides a sand core with a specific exhaust structure and a preparation method thereof. The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings to make it easier to understand and grasp.

[0033] A sand core with a specific exhaust structure, such as Figure 1 to Figure 3 As shown, it includes a metal wire skeleton 1, a high-temperature resistant exhaust fiber pipe 2 and a sand layer 3. The metal wire skeleton 1 is used for the molding support of the exhaust pipe of the sand core; the high temperature resistant exhaust fiber pipe 2 is used as the exhaust of the sand core The main body of the pipeline, the high temperature resistant exhaust fiber tube 2 is sleeved on the outer circumference of the metal wire frame 1, and the wall of the high temperature resistant exhaust fiber tube 2 is air-permeable; the sand layer 3 is cured and coated on the high temperature resistant exhaust fiber tub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com