Intensive repair method of molten chromium and molten carbon on the surface of non-uniform worn guide rail

A repair method and non-uniform technology, which is applied in the field of carbon-enhanced repair and chrome-melted surface of non-uniformly worn guide rails. It can solve the problems of guide rails that cannot meet the requirements of use, poor wear resistance, time-consuming and labor-intensive problems, and achieve non-uniform repair. range, anti-wear performance is stable and uniform, and the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

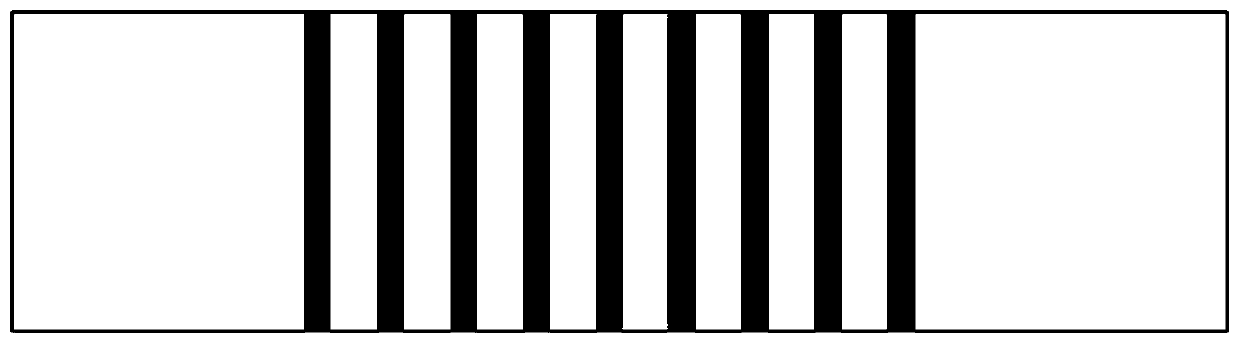

[0063] The surface hardness value of the guide rail is 300-420HV, and the hardness difference △H is 120HV. Since n=[△H / 100+0.5]=1, there is only one wear zone on the surface of the guide rail, which is set as zone A, and the standard hardness is Value H 0A =360HV. According to the relationship between the bionic surface and the hardness value of the wear zone, it can be known that the bionic surface S processed in the wear zone 2 . If M%=30% after repair is set, then by (h 0 -h w ') / h 0 = M% we can know h w '=(1-M%)×h 0 =0.5404μm, because 20%0A and h w =h w ' value is substituted into the biomimetic surface S composed of strip-shaped units 2 The wear resistance relation: h w =-0.00086×H+0.0026×θ+0.018×L+0.5705; get θ 0A =107.5-6.9×L 0A , so set the standard spacing L 0A After the value of θ can be obtained 0A , L 0A = 4 ~ 6mm, θ 0A =45°~90°. Divide zone A into 4 small hardness intervals, the hardness range of interval 1 is 300-330HV, and the average hardness v...

Embodiment 2

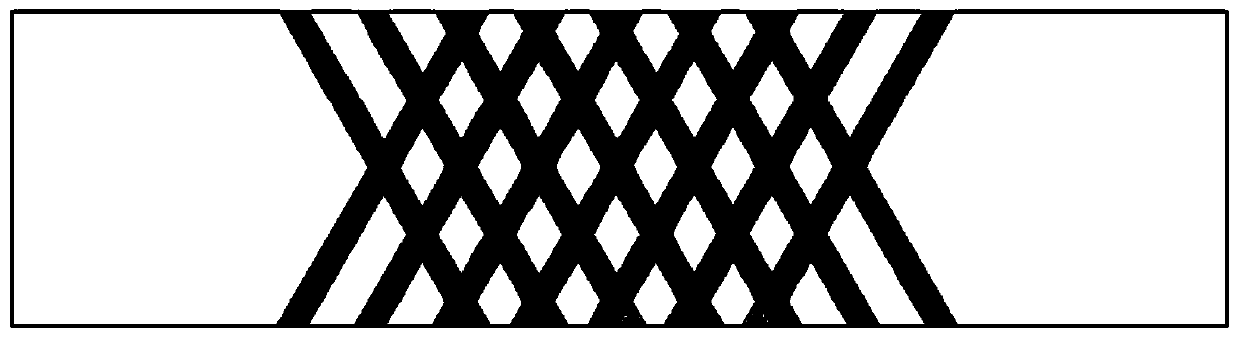

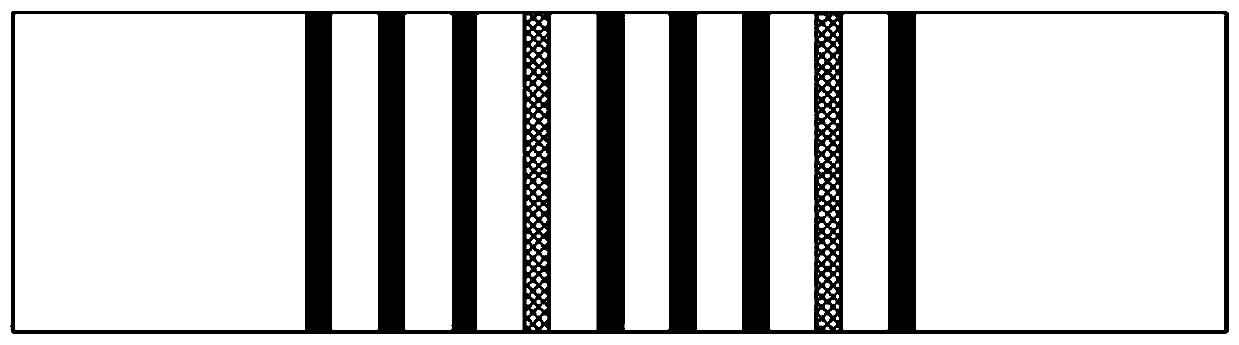

[0065] The surface hardness value of the guide rail is 300-580HV, and the hardness difference △H is 280HV. Since n=[△H / 100+0.5]=3, the surface of the guide rail is divided into three wear areas A, B, and C. A Zone hardness range 300 ~ 400HV, standard hardness value H 0A =350HV; the hardness range of B zone is 400~500HV, and the standard hardness value is H 0B =450HV; the hardness range of C zone is 500~580HV, and the standard hardness value is H 0C =540HV. According to the relationship between the bionic surface and the hardness value of the wear interval, it can be known that the bionic surface S processed in area A 2 , B area processing bionic surface S 3 , area C processing bionic surface S 4 . Set repaired M% = 50%, then by (h 0 -h w ') / h 0 = M% we can know h w '=(1-M%)×h 0 =0.386μm, because 40%0A and h w =h w ' value is substituted into the bionic surface S composed of mesh units 2 The wear resistance relation h w =-0.00061×H+0.0018×θ+0.013×L+0.4084, it can ...

Embodiment 3

[0067] The surface hardness value of the guide rail is 200-700HV, and the hardness difference △H is 500HV. Since n=[△H / 100+0.5]=5, the surface of the guide rail is divided into five parts: A, B, C, D, and E Wear zone, the hardness range of A zone is 200~300HV, and the standard hardness value is H 0A =250HV; the hardness range of B area is 300~400HV, and the standard hardness value is H 0B =350HV; the hardness range of C zone is 400~500HV, and the standard hardness value is H 0C =450HV; the hardness range of D zone is 500~600HV, and the standard hardness value is H 0D =550HV; the hardness range of E zone is 600~700HV, and the standard hardness value is H 0E =650HV. According to the relationship between the bionic surface and the hardness value of the wear interval, it can be known that the bionic surface S processed in area A 1 , B area processing bionic surface S 2 , area C processing bionic surface S 3 , area D processing bionic surface S 4 , E zone processing bionic s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com