Plastic particle screening device

A plastic granule and screening device technology, which is applied in the field of plastic manufacturing and processing, can solve the problem that plastic granules are easy to block the sieve holes, and achieve the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below by means of specific embodiments:

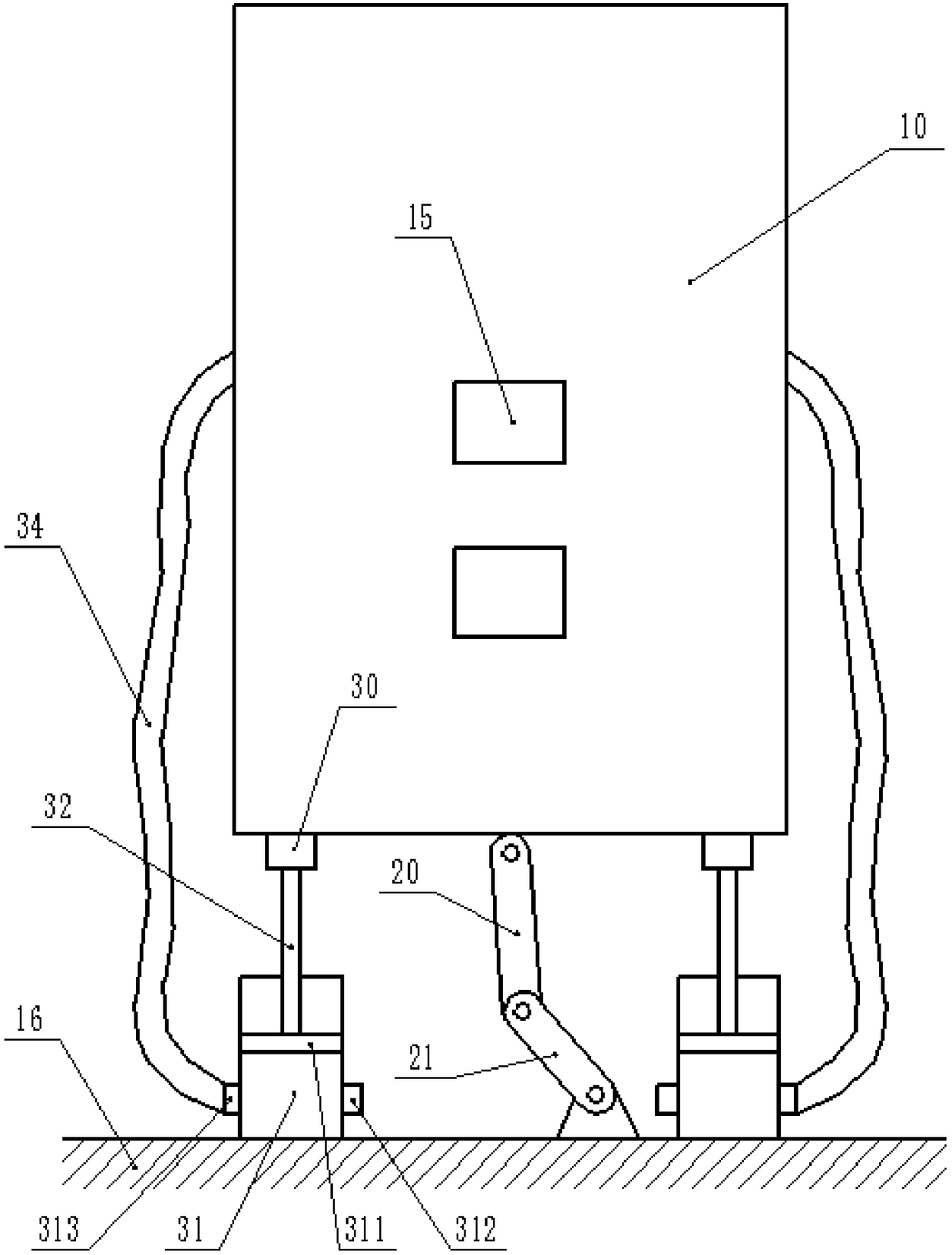

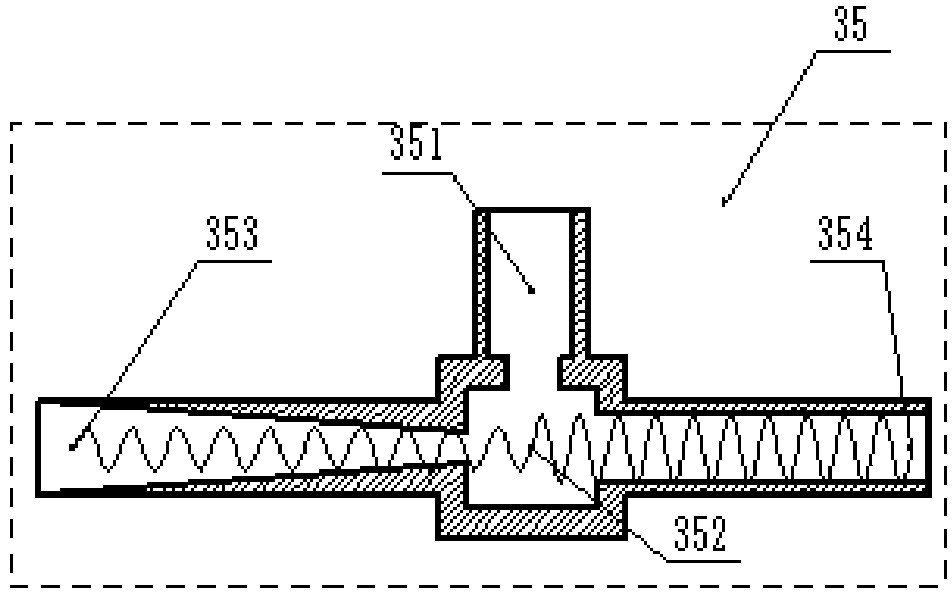

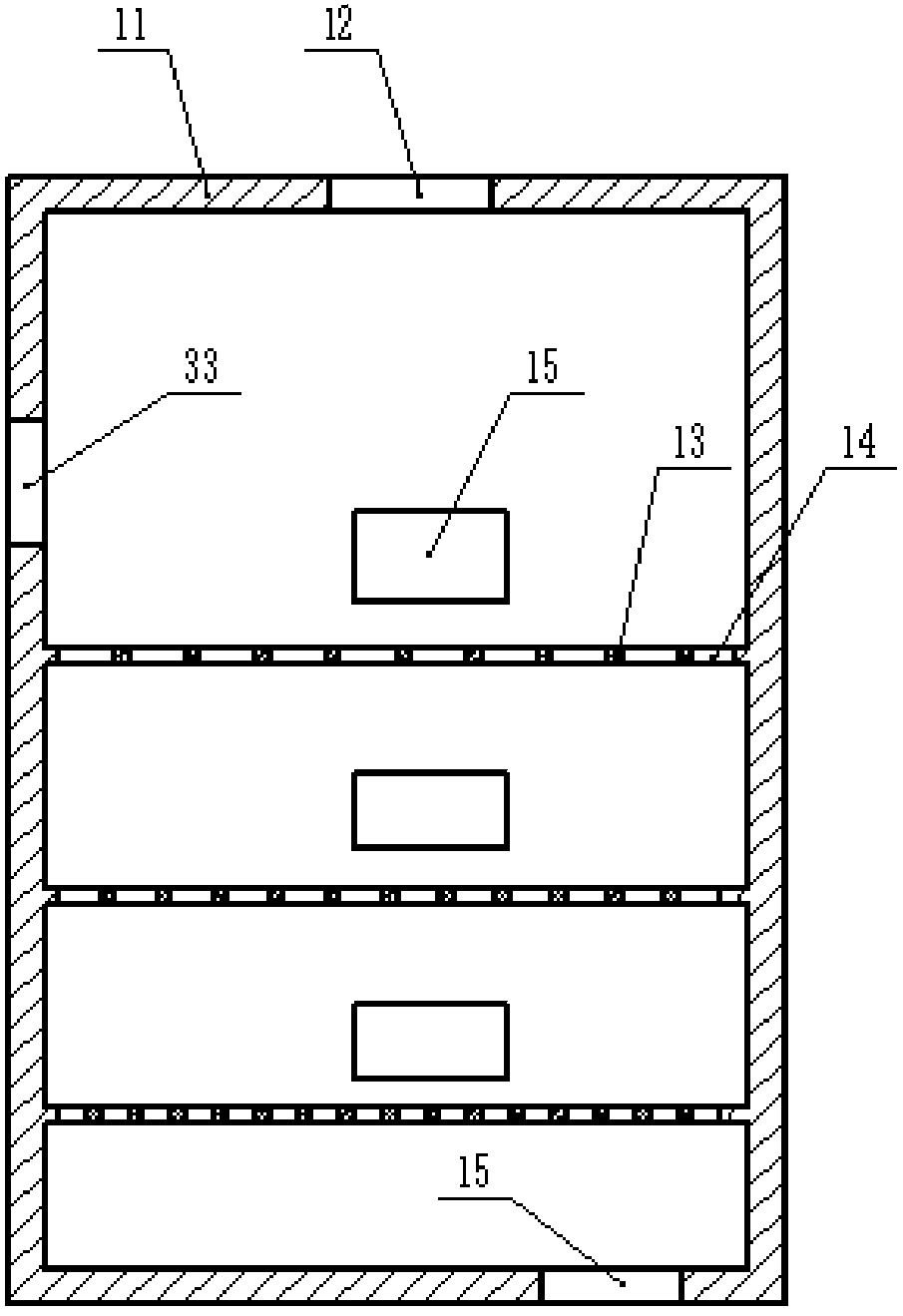

[0023] The reference signs in the accompanying drawings of the specification include: screening bucket 10, cover body 11, feed port 12, sieve plate 13, sieve hole 14, valve 15, frame 16, connecting rod 20, crank 21, mounting seat 30, Cylinder 31, piston rod 32, piston 311, inlet check valve 312, outlet check valve 313, air inlet 33, ventilation pipe 34, vortex pipe 35, air inlet end 351, vortex generator 352, cold air end 353, hot air End 354.

[0024] Examples of the present invention are figure 1 As shown, a plastic particle screening device is disclosed, including a screening bucket 10, a vibrating mechanism and an air supply system, wherein the vibrating structure is essentially a crank slider mechanism, including a connecting rod 20 hinged to the bottom of the screening bucket 10, a crank 21. One end is hinged to the connecting rod 20, and the other end is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com