Integrated reel-to-reel graphene continuous laminating device

A technology of laminating device and graphene, which is applied to the device for coating liquid on the surface, lamination device, lamination and other directions, can solve the problems of high quality control difficulty, poor appearance quality of finished products, high maintenance cost, and achieve appearance quality High, optimized fit quality, compact device effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

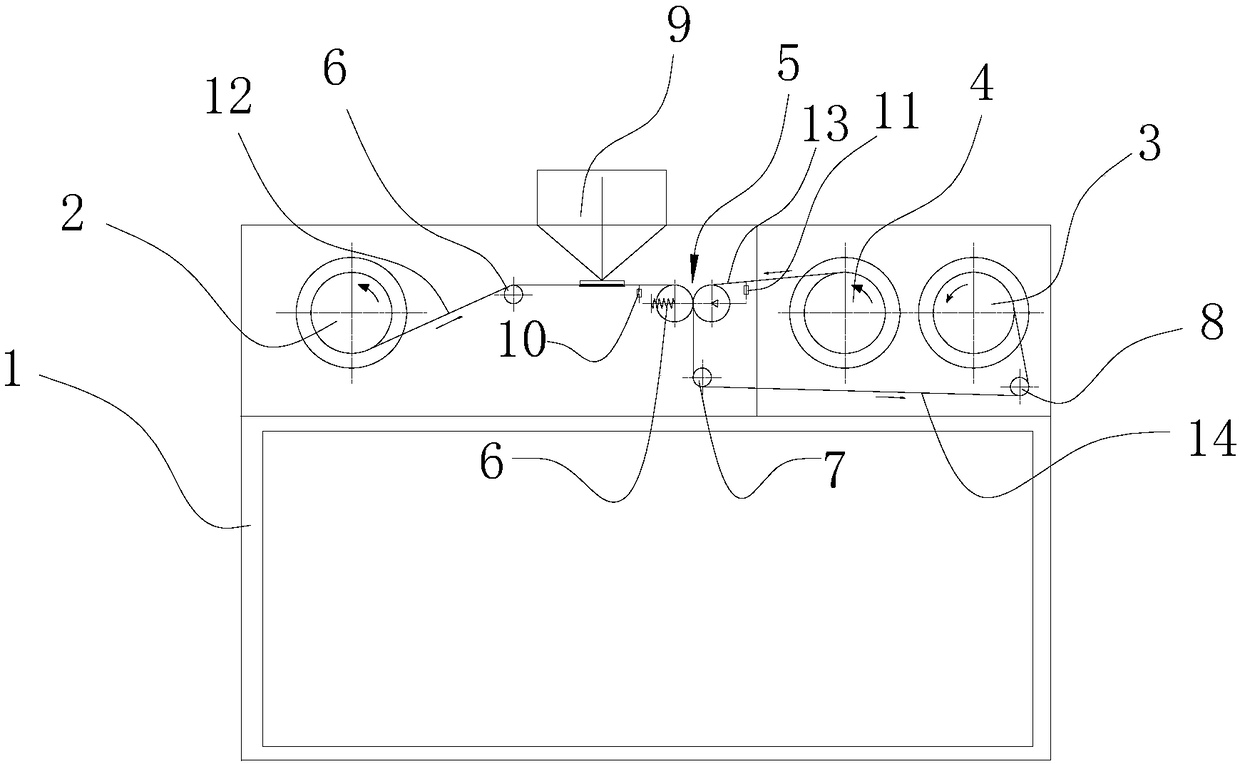

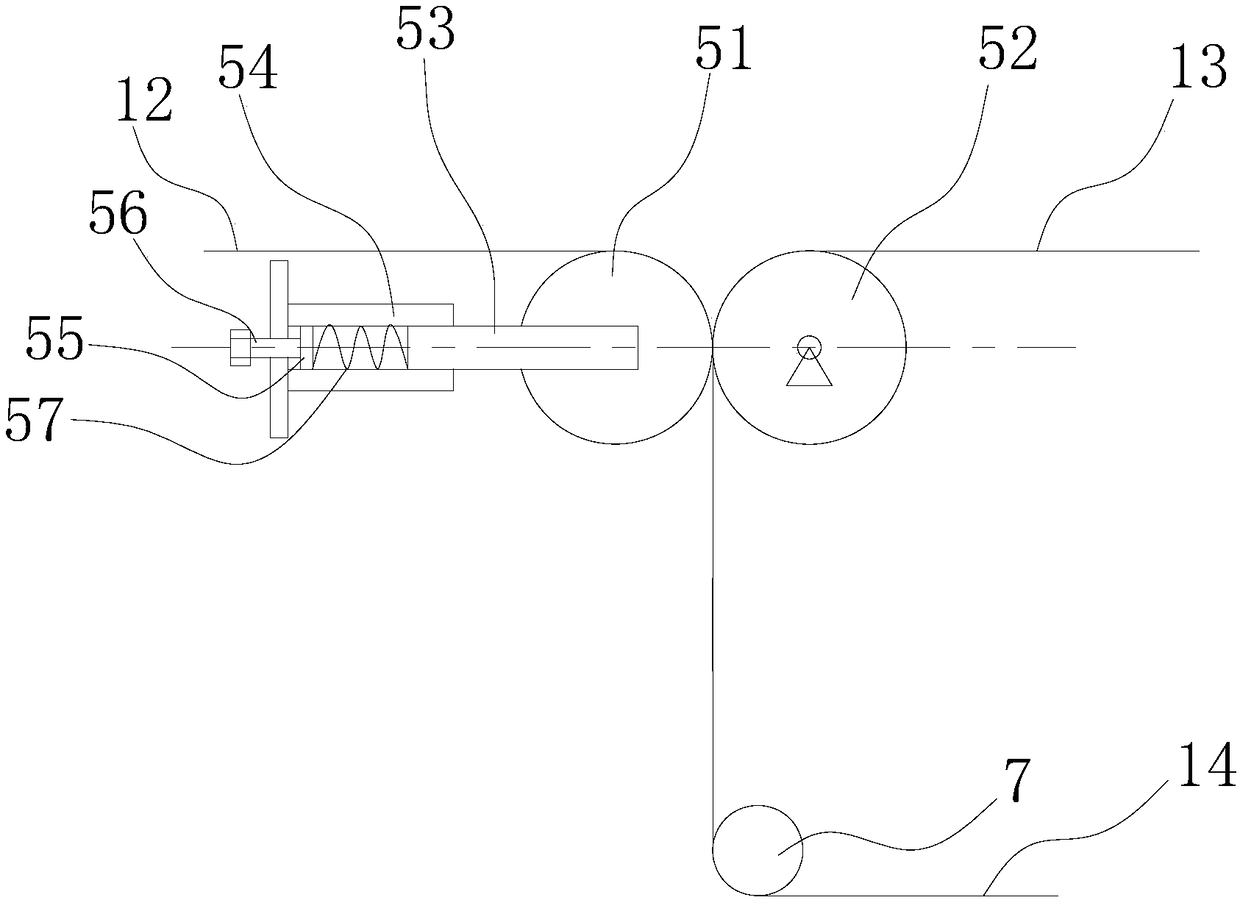

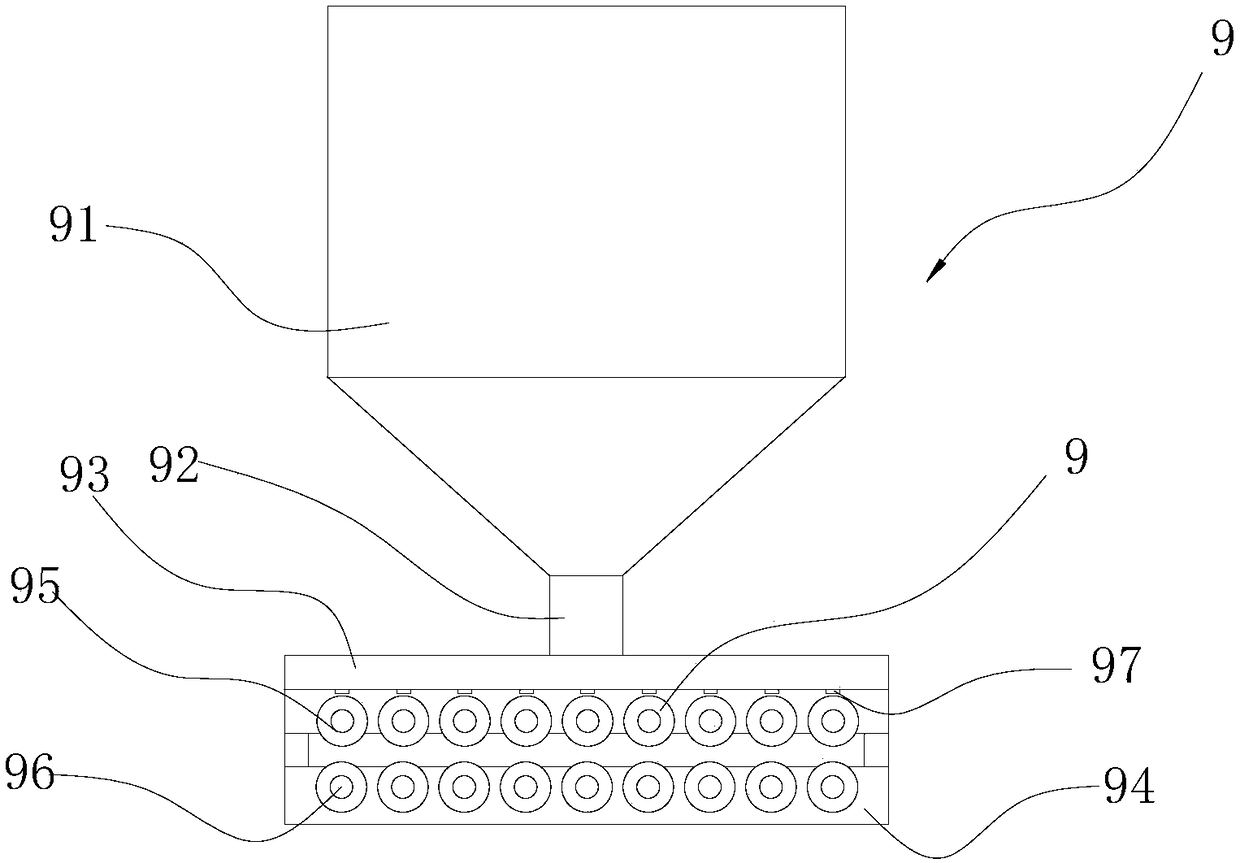

[0029] Such as Figure 1 to Figure 3 As shown, the present invention provides a kind of integrated roll-to-roll graphene continuous pasting device, comprises frame 1, and described frame 1 is provided with graphene semi-finished copper foil roll tension roller 2, gluing device 9, Finished roll tensioning roller 3, film-coated PET roll quick tensioning roll 4 and laminating device 5 with adjustable bonding force;

[0030] A first turning roller 6 is arranged between the graphene semi-finished copper foil coil tensioning roller 2 and the gluing device 9, and a second turning roller is arranged between the laminating device 5 and the finished product coil tensioning roller 3 7 and the third steering roller 8;

[0031] The graphene semi-finished copper foil roll tension roller 2 is tensioned with a graphene semi-finished copper foil roll, and the film-coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com